Автоматическая машина для резки стекла

Доступные автоматические машины для резки стекла на любой бюджет в 2025 году.

В компании LIJIANG Glass вы найдете различные самые популярные станки для резки стекла с комплектами загрузочных столов на любой бюджет и потребности.

Lijiang Glass offers high-quality, budget-friendly glass cutting machines for commercial, industrial, and architectural glass processing. Our 2025 automatic CNC glass cutting machines are trusted by glass factories, manufacturers, and workshops worldwide, including the USA, UK, UAE, Canada, Australia, Russia, South Africa, China, and India, as well as Asia, Europe, North America, South America, Africa, and Oceania. We provide custom glass cutting, washing & drying, loading & unloading, tempering, and insulated glass production lines to maximize efficiency and precision in every glass project.

Руководство по покупке автоматического станка для резки стекла

Руководство по покупке стекла LIJIANG здесь для вас — здесь есть наши рекомендации по главному вопросу: какой тип автоматической машины для резки стекла или линии резки стекла вам следует купить? Существует коллекция руководств по покупкам по категориям.

Правильные этапы работы стеклорезной машины

Когда мы используем автоматическую машину для резки стекла, мы должны заранее проверить стекло, которое нужно разрезать. Что касается внешнего вида стекла, то у нас не может быть появления белых пятен и царапин. Только после того, как самые основные условия будут квалифицированы, может быть осуществлено массовое производство. При измерении передний ряд должен быть объектом измерения, и при необходимости следует провести полную проверку.

Know More

Каковы рабочие характеристики автоматической машины для резки стекла

Сколько функций и преимуществ имеет автомат для резки стекла, как должен знать старший специалист в области обработки стекла, просто разобрать все оборудование для резки стекла и проанализировать рабочие характеристики оборудования для резки стекла с точки зрения механических, электрические и ПЛК системы управления...

Know More

Как выбрать оборудование для автоматической резки стекла?

С развитием рынка стекла в некоторых развивающихся странах также были разработаны автоматизированные машины и оборудование для обработки стекла. Среди них машины для резки стекла постепенно совершенствуются, и существует бесчисленное множество производителей. Как предприятие по производству стекла, как нам выбрать подходящее оборудование для резки стекла?

Know More

One article unlocks! Various application scenarios of architectural glass cutting table

Don't miss it! This article comprehensively shows how building glass cutting machines display their extraordinary capabilities and complete exquisite cutting in various building scenarios.

Know More

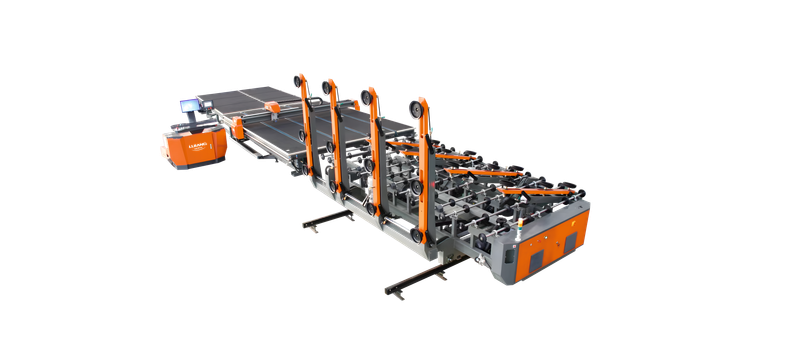

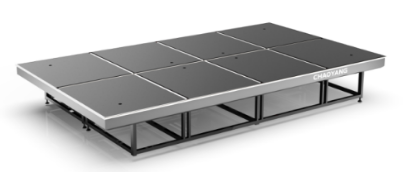

Автоматический стол для резки стекла | Эффективное решение для прямой и фигурной резки листового стекла

Автоматический стол для резки стекла — это высокопроизводительный станок для прямой и фигурной резки флоат-стекла. Его компактная конструкция подходит для цехов и производственных линий любого размера. Оснащенный ЧПУ и технологией прецизионной резки, он обрабатывает стекло толщиной от 2 до 19 мм с точностью ±0,15 мм, обеспечивая гладкие края и точные размеры. Благодаря автоматической загрузке, программному обеспечению для оптимизации раскроя и функции обнаружения трещин, он повышает производительность, снижает трудозатраты и уменьшает количество отходов. Идеально подходит для архитектурного, бытового, фасадного и декоративного стекла, предлагая стабильное, эффективное и неприхотливое в обслуживании решение для резки.

Automatic Glass Cutting Equipment

Выбор подходящего автоматического станка для резки стекла — одно из важнейших решений для любого производителя стекла. На рынке представлено множество вариантов, каждый из которых обещает точность, скорость и производительность, поэтому бывает сложно определить, какое оборудование действительно соответствует вашим производственным потребностям. В этом руководстве мы расскажем о ключевых факторах и четырёх проверенных шагах, которые помогут вам выбрать лучшее оборудование для резки стекла для вашей мастерской или промышленного предприятия.

Основной принцип работы

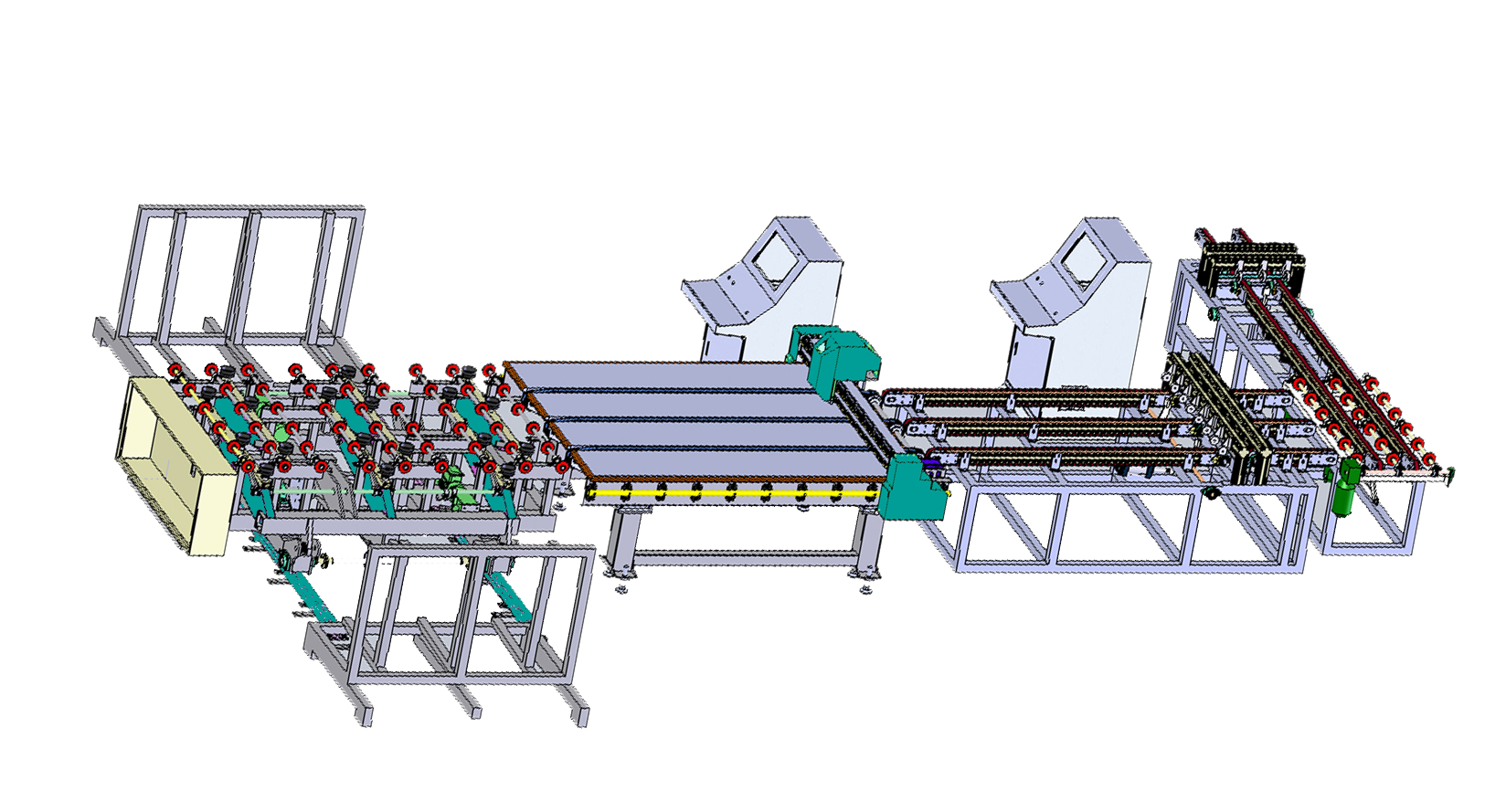

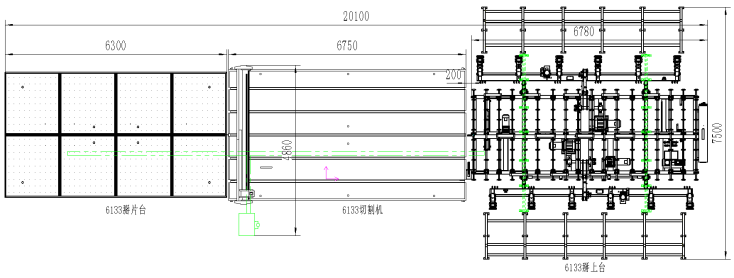

Полностью автоматическая линия подачи, резки и разбивания стекла

Полностью автоматическая линия подачи, резки и разбивания стекла Подробные рабочие шаги

Каждое действие может выполняться независимо или использоваться для обычной работы. После подачи сигнала на загрузку (ручного и автоматического) рычаг поворачивается вверх примерно на 95 градусов посредством механизма опрокидывания, и вся машина начинает двигаться вперед.

Когда индукционное устройство на рычаге касается стекла, вся машина останавливается. Вакуумная система работает: стекло всасывается присоской через вакуумные системы. Когда разрежение достигает заданного значения, вакуумный насос останавливается. Телескопический шатун присоски поднимает стекло назад и вверх на 80 мм с помощью электродвигателя подъема рычага.

Останавливаясь примерно на 1,5 секунды, чтобы убедиться, что стекло захвачено, большой рычаг, приводимый в движение двигателем, возвращает стекло к передаточному ролику. Присоска под стеклом начинает дуть, и телескопический стержень заставляет присоску и стекло одновременно опускаться.

Когда стекло падает на ролик конвейера, малый рычаг продолжает падать, стекло отделяется от присоски, и конвейер начинает отправлять стеклянный лист в передний конец загрузочной машины и останавливается в сигнальной точке. Затем вся рама автоматически перемещается, находит нулевое положение и останавливается.

Дождавшись сигнала от стола резки, стекло подается на стол резки с той же скоростью, что и конвейерная лента резательной машины. После выгрузки стекла рабочий цикл автоматически повторяется. Станок может выбрать любую позицию в зависимости от требуемой толщины стекла.

Технический параметр

- Размер листа: Минимальный размер: 2400*1500 мм (односторонняя загрузка)

- Максимальный размер загрузки: 6100*3300 мм

- Толщина листа стекла: 3 ~ 19 мм

- Рабочая глубина всасывания: 700 мм

- Скорость ходьбы по оси X: 5-25 м/мин (регулируемая)

- Скорость ходьбы по оси Y: 8-12 м/мин (регулируемая)

- Скорость подачи: 5-25 м/мин (регулируемая)

- Количество откидных рычагов: 12 рычагов (двусторонняя загрузка)

- Количество однорычажных присосок: три

- Тип загрузки: Двусторонняя загрузка

- Рабочий цикл: 60 с (30 с на каждую дополнительную позицию)

- Источник питания установки: переменный ток 380 В/50 Гц (особые условия могут быть скорректированы в соответствии с требованиями заказчика)

- Суммарная мощность установки: 8-17 кВт

- Сжатый воздух: 0,6-0,8 МПа;

- Вакуум: -50-99 кПа (регулируется в зависимости от толщины стекла)

- Высота рабочего стола: 900 + 20 мм

- Размер машины: 4650*2980*900 мм

Техническое описание

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line Основной принцип работы

Подробные рабочие шаги

- The chassis material is welded and formed by the national standard manganese-containing section bridge steel (Q345A) after aging treatment. The comprehensive mechanical properties, plasticity and welding properties of this kind of steel are good. The frame is processed as a whole, and the stability and accuracy of the equipment are greatly improved by tempering aging treatment to ensure the stability of the product. After special rust removal process, the surface rust spots and oxide layer are removed. The top coat is sprayed with high-grade epoxy primer and the top coat is sprayed with high-grade automobile paint.

- Through the analysis of professional structure software, the equipment ensures the stability, dynamic balance, mechanical strength to achieve the most perfect match, and ensures that the structure of the table is not deformed.

- The device has one key reset function. It can complete all the preparations before starting automatically by clicking on the touch screen, which greatly improves the work efficiency.

- Reasonable arrangement of integral cables and gas pipes and complete sealing

- High-speed silent linear guide is adopted for guide rail, which has high cutting accuracy and low noise.

- Advanced Japanese Ankawa servo motor is used in the driving part, which makes the equipment reliable, error small and efficient.

- Japanese SMC proportional solenoid valve is used for cutting rice. The pressure is automatically adjusted according to the glass thickness. The cutter head rotates 360 degrees, and the upper and lower buffering cutter cuts (any straight line and all kinds of special shaped glass can be cut accurately).

- The knife head is equipped with knife protection function. If the knife head falls outside the glass or the glass gap, the program stops automatically, effectively preventing damage to parts and glass.

- Double motor high speed drive (large inertia Yaskawa servo) ensures cutting speed and fluency;

- Conveyor device, synchronous automatic transmission device, convenient for glass upper and lower transmission, frequency conversion speed regulation, stable and easy to optimize the transmission speed;

- Positioning device, photoelectric scanning positioning system;

- Compensation function, tool eccentricity compensation, clearance compensation, pitch compensation.

Технический параметр

- Максимальный размер: 6100×3300 мм

- Толщина: 3~19 мм

- Точность резки: ±0,30

- Точность резки стекла специальной формы: ±0,35

- Скорость резки: 0-200 м/мин

- Скорость транспортировки: 0-25 м/мин

- Размеры машины: 6800×4100×1500 мм

- Высота рабочего стола: 900 мм±20 мм

- Вес: 2600 кг

- Общая мощность оборудования: 9-15 кВт

Техническое описание

Контроллер движения:

- Высокая скорость работы, плавность хода, высокая точность управления, модульная структура контроллера;

- Интерфейс «человек-машина» прост и широк, настройка параметров проста, число параметров, которые необходимо изменять операторам, меньше, они просты и интуитивно понятны, а требования к операторам невысокие.

- Режимы резки трубопровода, фотоэлектрического позиционирования и прямой резки свободно настраиваются с помощью опций. Автоматический режим резки и режим подачи воздуха могут быть переключены в любой момент обработки.

- Программирование раскладки графической библиотеки, выбор специальной формы из библиотеки, установка соответствующих параметров, количества обрабатываемых деталей, автоматическое раскладывание деталей, генерация траектории обработки;

- Полное хранение запасов стекла под давлением, после ввода и сохранения давления резки для каждой спецификации толщины его можно напрямую вызвать;

- Отслеживание и отображение в реальном времени пути обработки, своевременная регистрация координат движения, состояния осей, состояния ввода/вывода, автоматическая регистрация диагностики неисправностей и сигналов тревоги;

- Получает разнообразные документы по обработке, принимает стандартный G-код Optima, Super Package Software, файл AUTOCAD DXF, система имеет собственное программное обеспечение для редактирования графики (точно такое же, как метод редактирования Пола);

- Программирование раскладки графической библиотеки, выбор нестандартной формы из библиотеки, установка соответствующих параметров, объем обработки, автоматическая раскладка, генерация траектории обработки;

- Функция сортировки файлов класса DXF, включая сортировку по ближайшей точке, точке входа, по цвету изображения (по часовой стрелке, против часовой стрелки) и другие параметры. Реализовано свободное переключение между однофазной и двунаправленной резкой.

- Функция фотоэлектрического позиционирования, в соответствии с фактическим положением и углом отклонения, автоматически регулирует резку;

- Функция компенсации: компенсация эксцентриситета инструмента, компенсация зазора, компенсация шага;

- Все виды защиты: включая мягкое и жесткое ограничение, ограничение давления резака, внешнее управление аварийной остановкой и т. д.

Программное обеспечение для оптимизации:

- Импортируемые результаты оптимизации, выполненные в Office

- Схему раскроя можно создавать и редактировать вручную.

- С функциями копирования и мобильных устройств

- Ручное редактирование последовательности нарезки

- Схему резки можно быстро создать с помощью режимов X, Y и Z.

- Одновременная оптимизация нескольких исходных и небольших патчей

- Оптимизированный набор текста без ограничения размера

- Оптимизированное вращение результатов, управление зеркалами и т. д.

- Управление приоритетами для оптимизации резки мелких размеров

- Приоритетное управление оптимизацией исходного листа стекла

- Функция сканирования шаблонов и обработка сканирующей графики

- Управление хранением оригинальных листов стекла

- 20 эффективных алгоритмов оптимизации

- Резаную графику можно редактировать

- Дизайн и печать этикеток (Label-WAY)

- Четкая печать оптимизированного отчета о результатах

- Импорт файла данных Excel

- Управление резкой энергосберегающего стекла и клеевого стекла

- Графическая библиотека, содержащая 350 параметрических графических объектов, включая все наиболее часто используемые типы графики (Geo-Way)

- Двумерная САПР с функцией обработки нестандартного сканирования (Cad-Way)

- Автоматическое преобразование цифровых сигналов от систем ЧПУ в графические точки формовки

- Интерфейс программного обеспечения доступен на многих языках, включая кит

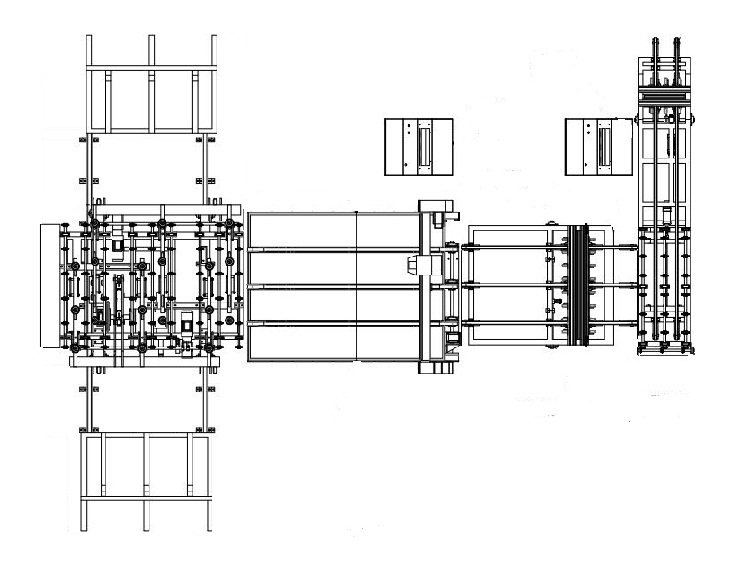

Автоматический стол для разбивания стекла с воздушным поплавком

Основной принцип работы

、Контактеры: Renmin/Zhengtai

、Автоматический выключатель: Жэньминь/Чжэнтай

、Кнопка: Жэньминь/Чжэнтай

、Главный электромагнитный клапан: Airtac

、Другие пневматические компоненты: Deke/Shengguan

、Вентилятор: Лиюань

механическая часть;

、Рабочий стол: водонепроницаемая пластина высокой плотности

、Стол: импортный промышленный войлок (черный)

、Разбивочная планка: массив дерева (натуральный цвет)

Примечание: В зависимости от даты поставки и технического усовершенствования компания-производитель оставляет за собой право замены купленных деталей той же марки.

Подробные рабочие шаги

- Функция предварительной стирки;

- Автоматически точное позиционирование для 3-х боковых ступеней DGU или 4-х боковых ступеней IGU;

- Автоматическое заполнение аргоном может устанавливать значение газа и отображать процесс заполнения в режиме онлайн с высокой концентрацией газа.

Технический параметр

- Разрывная планка: 3+1 тип

- Размер стола: 6300*3500 мм

- Толщина стекла: 3-19 мм

- Мощность: 8 кВт

- Высота стола: 900 + 20 мм

Техническое описание

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой Индивидуальный спрос и обслуживание

Закупка других машин для обработки стекла

Самый популярный- Приобретите другое автоматическое оборудование для обработки стекла (например, машину для закалки стекла и машину для производства изоляционного стекла) и экспортируйте их вместе с теми же контейнерами. Никаких затрат на закупку.

Установка и руководство оборудованием на месте

Самый популярный- Необходимо направить к этим пользователям терминала инженеров по послепродажному обслуживанию с многолетним опытом работы с руководством по установке и вводу в эксплуатацию автоматического оборудования на месте за 200 долларов США в день.

Уход за оборудованием Техническое обслуживание в течение всего жизненного цикла

Самый популярный- Предоставьте копию запасных частей и хрупких деталей, обычно используемых в автоматическом стекольном оборудовании, и приобретите их вместе, приняв на себя ответственность за полное техническое обслуживание этого стекольного оборудования.

Перепланируйте планировку цеха вашего стекольного завода

Самый популярный- Основываясь на многолетнем опыте в обработке стекла, компания LIJIANG Glas предоставит клиентам разумные предложения по перепланировке цеха вашего стекольного завода с точки зрения водоснабжения, электроснабжения, размещения, эффективного улучшения...

Записаться на производство

Sales Promotion & Discounts

LIJAING Glass After-Sales Department will help you if you have any questions or problems – the range of services at your disposal includes everything from start-up to product returns.

If necessary, a member of our staff will be on the site within a very short period to work together with you and to take care of your issues and interests. Our employees in after-sales service are not only glass experts—they are also qualified in many other specific areas. For example, our team includes experienced designers who are pleased to provide any additional glass cutting machine suggestions for any specific events.

Все об автоматической резке стекла

При выборе и использовании полностью автоматического станка для резки стекла следует уделять внимание таким аспектам, как производительность оборудования, простота эксплуатации и послепродажное обслуживание, чтобы обеспечить эффективность производства и качество продукции предприятий по переработке стекла.

Распространенные неисправности и методы устранения неисправностей автоматических станков для резки стекла

- Glass cutting speed decreases or glass cutting diagonal changes

Troubleshooting method:

(1) Open the cover of both sides of the panel;

(2) Loosen the tension sleeves on both sides;

(3) Adjust the tightness of the timing belts on both sides to be consistent.

- After the cutting line is removed, the glass cannot be cut through and cannot be broken.

Troubleshooting methods:

(1) Adjust the angle of the cutter wheel;

(2) Replace the appropriate cutter wheel.

- Cutting line glass cutting edge exposed edge

Troubleshooting methods:

(1) Inject lubricating oil;

(2) Reduce the knife pressure.

- The set cutting size becomes larger or smaller than the actual machine operating size.

Troubleshooting method: Adjust the settings of the cutting machine driver.

- No floating function

Reason: The air path may be blocked, the fan is damaged or the air source triplex is blocked.

Troubleshooting methods:

(1) Clear the air path and triple components;

(2) Replace the fan.

- After the operation panel is set, the cutting head cannot automatically return to the mechanical origin.

Reason: It may be that the proximity switch for returning to the mechanical origin is damaged.

Troubleshooting method: Replace the origin switch.

- No positive or negative limit

Reason: The positive and negative limit switches are damaged.

Troubleshooting method: Replace the limit switch with a new one.

- The computer cannot find the board (hardware)

Reason: Usually caused by poor contact with the board.

Troubleshooting method: Remove the board card from the PCI slot and reinsert it tightly.

- Servo overvoltage alarm

It is caused by the wrong connection between the servo motor power supply and the ground wire. Just correct the wrong wire connection.

- Encoder communication protection

The encoder address book wire is weakly welded or broken, just re-solder the encoder wire.

- The servo motor vibrates too much

Reason: The fasteners are loose or the motor is too rigid.

Troubleshooting methods:

(1) Adjust the tightness of the rotating parts;

(2) Reduce the rigidity of the servo motor.

Know More

Какой автоматический станок для резки стекла вам больше подойдет?

The manual glass cutting machine is the most traditional glass cutting machine. The entire machine consists of two parts: a glass conveyor belt and a cutting table. By operating the conveyor belt manually, the glass to be cut is transported to the cutting table for cutting with a blade. The advantage of this cutting machine is that it can cut relatively small pieces of special-shaped glass and process the glass into different shapes. The disadvantage is that cutting the glass into a unique shape requires a special mold, and the manual operation itself is time-consuming and labor-intensive, making mass production impossible.Manual glass-cutting machine

This kind of glass cutting machine is roughly the same as a manual cutting machine, but a semi-automatic button operation device is added to the cutting machine. Although it is still mainly used to cut special-shaped glass, and special molds need to be made in advance according to the shape of the glass, the size of the glass that can be processed is larger than that of a manual cutting machine. And because it uses pneumatic plus motor kinetic energy during cutting, it saves a lot of manpower, so the production efficiency is much higher than that of manual cutting machines.Semi-automatic glass cutting machine

This glass cutting machine is a step further than semi-automatic glass cutting machines. It consists of a chassis mechanism, a beam mechanism, a glass processing tabletop, a cutter head mechanism, a conveying mechanism, a mechanical positioning mechanism, an electrical control system, etc., and has a complex structure.Fully automatic glass cutting machine

Its processing method is controlled by the computer software equipped with the machine, which directly draws and then performs the operation. In this way, you can set in advance whether to make square, round, or special-shaped glass through the computer, without making a mold in advance.

The most advanced form of this kind of cutting machine is the production line model. In addition to the film-loading table, computer cutting machine, and film-breaking machine, this model also has a film-unloading table. The whole process of the assembly line is computer-controlled, with a high degree of automation, and is suitable for long periods. It can handle large quantities of glass products and is easy to maintain.

When cutting with a fully automatic glass cutting machine, typesetting is required first, and then cutting, film removal, and other processes can be carried out. Not only is it required to discharge as many pieces as possible that meet the required shape on the original glass sheet to improve the utilization rate of raw materials, but it is also required that the typesetting operation is simple and easy to use. Mechanical interactive typesetting is the most commonly used and convenient way for operators to type and cut according to the work order on site.

This kind of glass cutting machine also operates fully automatically through computer control. But unlike traditional blade cutting, it uses high-pressure water cutting technology, mainly for thicker glass products. Various complex patterns are formed through computer numerical control. This cutting machine performs cold cutting without producing thermal deformation or thermal effects. It can ensure smooth incision and can be completed in one go without the need for secondary operations. Due to these advantages, it can also perform complex operations of drilling glass.Water jet glass cutting machine

Каковы стандартные этапы работы автоматических станков для резки стекла?

2. Check that there are no white spots or scratches on the appearance of the glass to be cut.

3. Push the longitudinal beam, and then push the cross beam after returning to its position to prevent collision with each other.

4. Before starting the machine, check whether there is air leakage in the machine pipeline. If there is air leakage, never start the machine.

5. Turn on the power switch and check whether there are any obstacles on the working surface and guide rails. If there are any obstacles, they must be removed.

6. Two people lift the glass to be cut to the cutting table, making sure it is firmly attached to prevent shaking. Before lifting the glass, you must confirm that there are no cracks in the glass itself to avoid the phenomenon of automatic separation of the glass during lifting.

7. Press the blow button to make the glass float on the table and move freely.

8. After the glass is positioned, press the stop button, and then press the suction device to firmly fix the glass at the designated position to achieve the positioning effect.

9. When the cutting is completed, press the stop button and then press the air blow switch.

10. When the whole piece of glass that has been cut is moved to the breaking table, turn on the blowing motor of the breaking table before moving. Only after the first piece is confirmed to be qualified can it be mass-produced. When measuring, the first row horizontally and vertically is used as the measurement object, and a full inspection is performed if necessary.

11. Divide the dough into small pieces horizontally and vertically according to the knife marks, and place the remaining material in the designated position. Stack the broken pieces of glass neatly and place them on the glass shelf.

12. Before shutting down, close all air valves and vent the remaining gas in the air circuit. If a backfire is found in the pipeline, the power and gas must be cut off immediately.

13. Use a rag to clean the glass fragments on the cutting table and breaking table.

Как выбрать автоматический станок для резки стекла?

It seems that the model of the automatic glass cutting machine is composed of a simple string of letters and numbers, but it represents the factory age, technical equipment, and other contents of the cutting machine, so you should first determine which series of equipment you want to buy, and then distinguish the differences between different models. After all, each customer will set a budget first, and then purchase a cost-effective machine under a reasonable budget.

In addition, you should also look at the specific parameters of the automatic glass cutting machine, such as the cutting efficiency and the whole machine service mode. These parameters determine whether the equipment is convenient to use and the technical level of the equipment itself. What we have to do is to purchase machines with high precision and high speed as much as possible, so as not to delay future use.

The above are the precautions for purchasing automatic glass-cutting machines. In fact, in addition to purchasing specialists, if you can bring factory technicians, they come from the front line of operation, will be very familiar with the technology and use of the cutting machine, and will also give reasonable suggestions during the trial to avoid detours.

People can visit several automatic glass cutting machine manufacturers and compare automatic glass-cutting machines of different models and batches. I believe that they will have a deeper understanding of the industry and will be more adept at purchasing.

Какие части включает в себя автоматическая линия резки стекла?

To judge the performance of the glass cutting line, you need to look at the material of the whole machine to see if it has passed the national standard. At the same time, you should also judge the details, such as whether it has been oxidized to prevent rust. Is the vacuum degree and reliability achieved? If a system is not set up perfectly, it will inevitably affect the operation of the entire line, so you must be careful when checking.

For technicians, people especially hope that the glass cutting line has a one-button reset function, so that there is no need to operate it repeatedly, and it can also speed up the timeliness and speed of preparation work. For safety reasons, the equipment especially needs to have an alarm device, so that an alarm can be issued when the operation is not professional. People can repair and maintain according to the alarm, and they can also have a better understanding of the machine equipment.

The glass cutting line is relatively complex, and its mechanical configuration is very complete. Most of them adopt high-precision and high-density designs, which not only beautify the compactness of the appearance but also do not affect everyone's use. The indicators for reference when purchasing include the external dimensions, the size and thickness of the film, the film retrieval cycle, and also include power supply, power, etc.

The above is a specific introduction to the glass cutting line. It can be seen that the requirements for purchasing personnel are very high. Only by fully understanding the various components of the line can the purchase process be handy and the budget can be made to meet the factory's expectations. At present, many glass-cutting line manufacturers will carry out structural optimization work, to continuously upgrade technology and launch new products.