Automatic Glass Cutting Equipment

Выбор подходящего автоматического станка для резки стекла — одно из важнейших решений для любого производителя стекла. На рынке представлено множество вариантов, каждый из которых обещает точность, скорость и производительность, поэтому бывает сложно определить, какое оборудование действительно соответствует вашим производственным потребностям. В этом руководстве мы расскажем о ключевых факторах и четырёх проверенных шагах, которые помогут вам выбрать лучшее оборудование для резки стекла для вашей мастерской или промышленного предприятия.

Основной принцип работы

Он в основном используется для автоматической загрузки стекла. После установки стекла в указанное положение и подачи сигнала о загрузке, большой рычаг через опрокидывающий механизм поворачивается примерно на 95 градусов, и вся машина начинает двигаться вперед. Когда индукционное устройство на маленьком рычаге касается стекла, вся машина останавливается, и стекло всасывается присоской через вакуумную систему на стекле, двигатель подъема маленького рычага поднимает стекло вверх и назад примерно на 80 мм. Шагающий двигатель отступает, и большая рука падает. Когда приводной рычаг находится на месте, присоска под стеклом начинает дуть. Когда стрела падает вниз, стекло падает на конвейерное колесо. Наконец, стекло транспортируется к режущему столу конвейерным колесом.

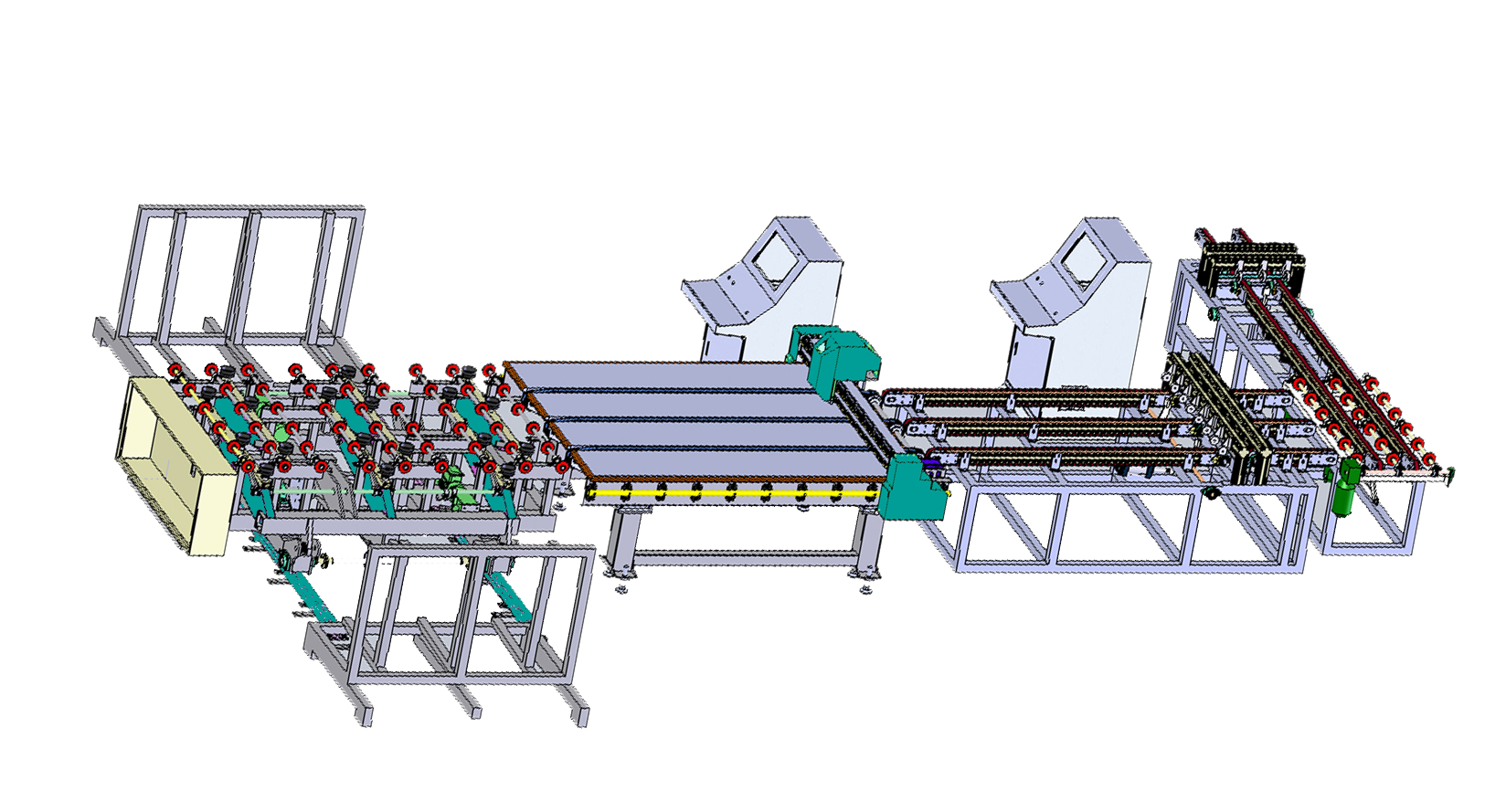

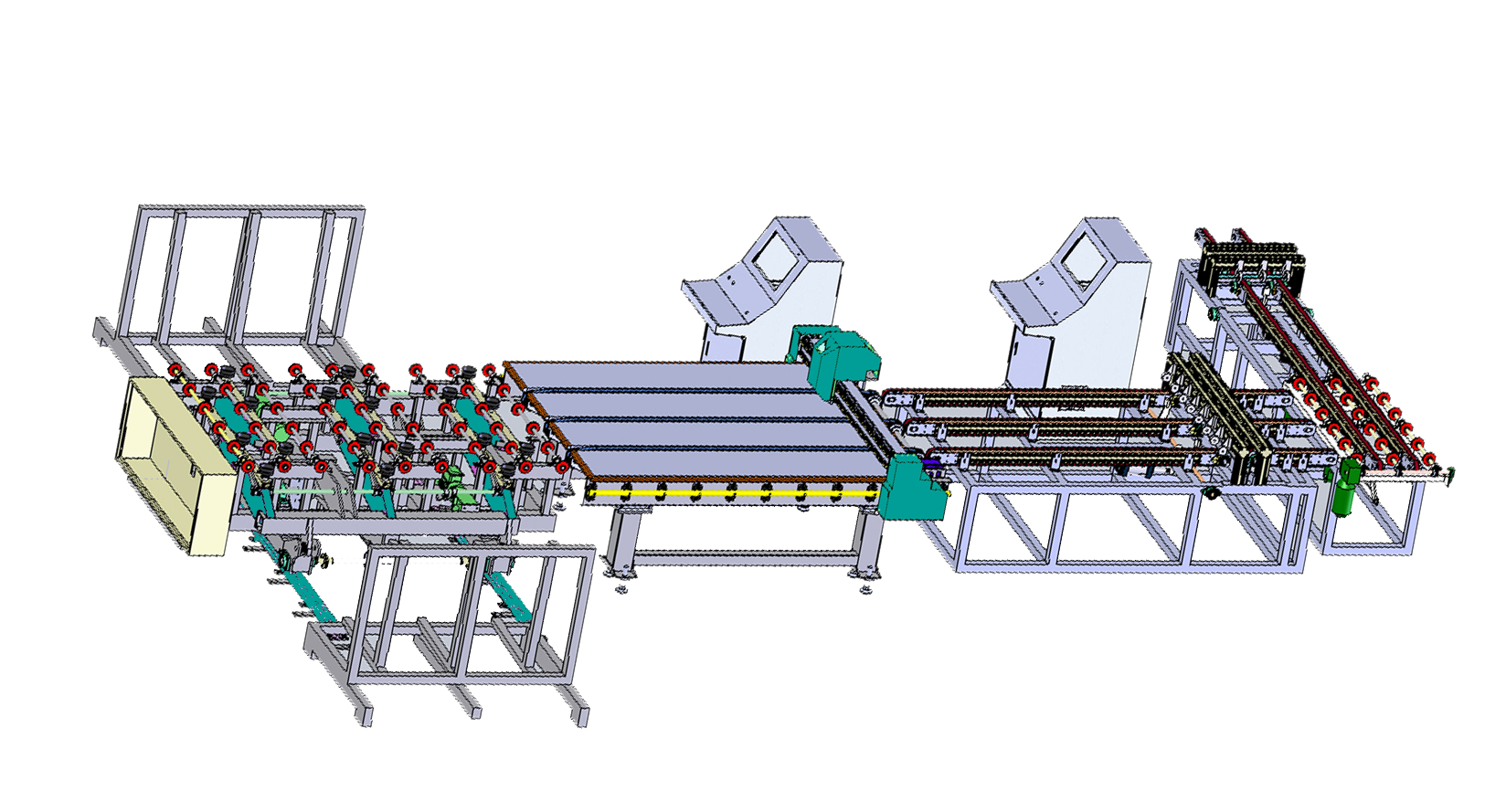

Полностью автоматическая линия подачи, резки и разбивания стекла

Полностью автоматическая линия подачи, резки и разбивания стекла

Полностью автоматическая линия подачи, резки и разбивания стекла

Полностью автоматическая линия подачи, резки и разбивания стекла Подробные рабочие шаги

Весь рабочий процесс может осуществляться автоматически с помощью ПЛК или вручную. Ручной режим в основном подходит для настройки и обслуживания оборудования.

Каждое действие может выполняться независимо или использоваться для обычной работы. После подачи сигнала на загрузку (ручного и автоматического) рычаг поворачивается вверх примерно на 95 градусов посредством механизма опрокидывания, и вся машина начинает двигаться вперед.

Когда индукционное устройство на рычаге касается стекла, вся машина останавливается. Вакуумная система работает: стекло всасывается присоской через вакуумные системы. Когда разрежение достигает заданного значения, вакуумный насос останавливается. Телескопический шатун присоски поднимает стекло назад и вверх на 80 мм с помощью электродвигателя подъема рычага.

Останавливаясь примерно на 1,5 секунды, чтобы убедиться, что стекло захвачено, большой рычаг, приводимый в движение двигателем, возвращает стекло к передаточному ролику. Присоска под стеклом начинает дуть, и телескопический стержень заставляет присоску и стекло одновременно опускаться.

Когда стекло падает на ролик конвейера, малый рычаг продолжает падать, стекло отделяется от присоски, и конвейер начинает отправлять стеклянный лист в передний конец загрузочной машины и останавливается в сигнальной точке. Затем вся рама автоматически перемещается, находит нулевое положение и останавливается.

Дождавшись сигнала от стола резки, стекло подается на стол резки с той же скоростью, что и конвейерная лента резательной машины. После выгрузки стекла рабочий цикл автоматически повторяется. Станок может выбрать любую позицию в зависимости от требуемой толщины стекла.

Каждое действие может выполняться независимо или использоваться для обычной работы. После подачи сигнала на загрузку (ручного и автоматического) рычаг поворачивается вверх примерно на 95 градусов посредством механизма опрокидывания, и вся машина начинает двигаться вперед.

Когда индукционное устройство на рычаге касается стекла, вся машина останавливается. Вакуумная система работает: стекло всасывается присоской через вакуумные системы. Когда разрежение достигает заданного значения, вакуумный насос останавливается. Телескопический шатун присоски поднимает стекло назад и вверх на 80 мм с помощью электродвигателя подъема рычага.

Останавливаясь примерно на 1,5 секунды, чтобы убедиться, что стекло захвачено, большой рычаг, приводимый в движение двигателем, возвращает стекло к передаточному ролику. Присоска под стеклом начинает дуть, и телескопический стержень заставляет присоску и стекло одновременно опускаться.

Когда стекло падает на ролик конвейера, малый рычаг продолжает падать, стекло отделяется от присоски, и конвейер начинает отправлять стеклянный лист в передний конец загрузочной машины и останавливается в сигнальной точке. Затем вся рама автоматически перемещается, находит нулевое положение и останавливается.

Дождавшись сигнала от стола резки, стекло подается на стол резки с той же скоростью, что и конвейерная лента резательной машины. После выгрузки стекла рабочий цикл автоматически повторяется. Станок может выбрать любую позицию в зависимости от требуемой толщины стекла.

Технический параметр

- Размер листа: Минимальный размер: 2400*1500 мм (односторонняя загрузка)

- Максимальный размер загрузки: 6100*3300 мм

- Толщина листа стекла: 3 ~ 19 мм

- Рабочая глубина всасывания: 700 мм

- Скорость ходьбы по оси X: 5-25 м/мин (регулируемая)

- Скорость ходьбы по оси Y: 8-12 м/мин (регулируемая)

- Скорость подачи: 5-25 м/мин (регулируемая)

- Количество откидных рычагов: 12 рычагов (двусторонняя загрузка)

- Количество однорычажных присосок: три

- Тип загрузки: Двусторонняя загрузка

- Рабочий цикл: 60 с (30 с на каждую дополнительную позицию)

- Источник питания установки: переменный ток 380 В/50 Гц (особые условия могут быть скорректированы в соответствии с требованиями заказчика)

- Суммарная мощность установки: 8-17 кВт

- Сжатый воздух: 0,6-0,8 МПа;

- Вакуум: -50-99 кПа (регулируется в зависимости от толщины стекла)

- Высота рабочего стола: 900 + 20 мм

- Размер машины: 4650*2980*900 мм

Техническое описание

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line Основной принцип работы

Принцип работы заключается в подаче отрезанного стекла по конвейерной ленте к рабочему столу, автоматическом вводе положения стекла с помощью фотоэлектрической системы сканирования, после чего режущая головка с алмазным диском на держателе резака перемещается по осям X и Y соответственно под управлением программы, обрезая лист. В блоке управления станка используется контроллер движения с ЧПУ, а в блоке привода — усовершенствованный серводвигатель переменного тока.

Подробные рабочие шаги

- The chassis material is welded and formed by the national standard manganese-containing section bridge steel (Q345A) after aging treatment. The comprehensive mechanical properties, plasticity and welding properties of this kind of steel are good. The frame is processed as a whole, and the stability and accuracy of the equipment are greatly improved by tempering aging treatment to ensure the stability of the product. After special rust removal process, the surface rust spots and oxide layer are removed. The top coat is sprayed with high-grade epoxy primer and the top coat is sprayed with high-grade automobile paint.

- Through the analysis of professional structure software, the equipment ensures the stability, dynamic balance, mechanical strength to achieve the most perfect match, and ensures that the structure of the table is not deformed.

- The device has one key reset function. It can complete all the preparations before starting automatically by clicking on the touch screen, which greatly improves the work efficiency.

- Reasonable arrangement of integral cables and gas pipes and complete sealing

- High-speed silent linear guide is adopted for guide rail, which has high cutting accuracy and low noise.

- Advanced Japanese Ankawa servo motor is used in the driving part, which makes the equipment reliable, error small and efficient.

- Japanese SMC proportional solenoid valve is used for cutting rice. The pressure is automatically adjusted according to the glass thickness. The cutter head rotates 360 degrees, and the upper and lower buffering cutter cuts (any straight line and all kinds of special shaped glass can be cut accurately).

- The knife head is equipped with knife protection function. If the knife head falls outside the glass or the glass gap, the program stops automatically, effectively preventing damage to parts and glass.

- Double motor high speed drive (large inertia Yaskawa servo) ensures cutting speed and fluency;

- Conveyor device, synchronous automatic transmission device, convenient for glass upper and lower transmission, frequency conversion speed regulation, stable and easy to optimize the transmission speed;

- Positioning device, photoelectric scanning positioning system;

- Compensation function, tool eccentricity compensation, clearance compensation, pitch compensation.

Технический параметр

- Максимальный размер: 6100×3300 мм

- Толщина: 3~19 мм

- Точность резки: ±0,30

- Точность резки стекла специальной формы: ±0,35

- Скорость резки: 0-200 м/мин

- Скорость транспортировки: 0-25 м/мин

- Размеры машины: 6800×4100×1500 мм

- Высота рабочего стола: 900 мм±20 мм

- Вес: 2600 кг

- Общая мощность оборудования: 9-15 кВт

Техническое описание

Программная часть:

Контроллер движения:

Программное обеспечение для оптимизации:

Контроллер движения:

- Высокая скорость работы, плавность хода, высокая точность управления, модульная структура контроллера;

- Интерфейс «человек-машина» прост и широк, настройка параметров проста, число параметров, которые необходимо изменять операторам, меньше, они просты и интуитивно понятны, а требования к операторам невысокие.

- Режимы резки трубопровода, фотоэлектрического позиционирования и прямой резки свободно настраиваются с помощью опций. Автоматический режим резки и режим подачи воздуха могут быть переключены в любой момент обработки.

- Программирование раскладки графической библиотеки, выбор специальной формы из библиотеки, установка соответствующих параметров, количества обрабатываемых деталей, автоматическое раскладывание деталей, генерация траектории обработки;

- Полное хранение запасов стекла под давлением, после ввода и сохранения давления резки для каждой спецификации толщины его можно напрямую вызвать;

- Отслеживание и отображение в реальном времени пути обработки, своевременная регистрация координат движения, состояния осей, состояния ввода/вывода, автоматическая регистрация диагностики неисправностей и сигналов тревоги;

- Получает разнообразные документы по обработке, принимает стандартный G-код Optima, Super Package Software, файл AUTOCAD DXF, система имеет собственное программное обеспечение для редактирования графики (точно такое же, как метод редактирования Пола);

- Программирование раскладки графической библиотеки, выбор нестандартной формы из библиотеки, установка соответствующих параметров, объем обработки, автоматическая раскладка, генерация траектории обработки;

- Функция сортировки файлов класса DXF, включая сортировку по ближайшей точке, точке входа, по цвету изображения (по часовой стрелке, против часовой стрелки) и другие параметры. Реализовано свободное переключение между однофазной и двунаправленной резкой.

- Функция фотоэлектрического позиционирования, в соответствии с фактическим положением и углом отклонения, автоматически регулирует резку;

- Функция компенсации: компенсация эксцентриситета инструмента, компенсация зазора, компенсация шага;

- Все виды защиты: включая мягкое и жесткое ограничение, ограничение давления резака, внешнее управление аварийной остановкой и т. д.

Программное обеспечение для оптимизации:

- Импортируемые результаты оптимизации, выполненные в Office

- Схему раскроя можно создавать и редактировать вручную.

- С функциями копирования и мобильных устройств

- Ручное редактирование последовательности нарезки

- Схему резки можно быстро создать с помощью режимов X, Y и Z.

- Одновременная оптимизация нескольких исходных и небольших патчей

- Оптимизированный набор текста без ограничения размера

- Оптимизированное вращение результатов, управление зеркалами и т. д.

- Управление приоритетами для оптимизации резки мелких размеров

- Приоритетное управление оптимизацией исходного листа стекла

- Функция сканирования шаблонов и обработка сканирующей графики

- Управление хранением оригинальных листов стекла

- 20 эффективных алгоритмов оптимизации

- Резаную графику можно редактировать

- Дизайн и печать этикеток (Label-WAY)

- Четкая печать оптимизированного отчета о результатах

- Импорт файла данных Excel

- Управление резкой энергосберегающего стекла и клеевого стекла

- Графическая библиотека, содержащая 350 параметрических графических объектов, включая все наиболее часто используемые типы графики (Geo-Way)

- Двумерная САПР с функцией обработки нестандартного сканирования (Cad-Way)

- Автоматическое преобразование цифровых сигналов от систем ЧПУ в графические точки формовки

- Интерфейс программного обеспечения доступен на многих языках, включая кит

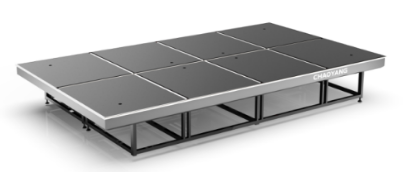

Автоматический стол для разбивания стекла с воздушным поплавком

LIJIANG Стекло - Тип: LJ-BP-6133 (тип 3+1)

Основной принцип работы

Электрическая часть:

、Контактеры: Renmin/Zhengtai

、Автоматический выключатель: Жэньминь/Чжэнтай

、Кнопка: Жэньминь/Чжэнтай

、Главный электромагнитный клапан: Airtac

、Другие пневматические компоненты: Deke/Shengguan

、Вентилятор: Лиюань

механическая часть;

、Рабочий стол: водонепроницаемая пластина высокой плотности

、Стол: импортный промышленный войлок (черный)

、Разбивочная планка: массив дерева (натуральный цвет)

Примечание: В зависимости от даты поставки и технического усовершенствования компания-производитель оставляет за собой право замены купленных деталей той же марки.

、Контактеры: Renmin/Zhengtai

、Автоматический выключатель: Жэньминь/Чжэнтай

、Кнопка: Жэньминь/Чжэнтай

、Главный электромагнитный клапан: Airtac

、Другие пневматические компоненты: Deke/Shengguan

、Вентилятор: Лиюань

механическая часть;

、Рабочий стол: водонепроницаемая пластина высокой плотности

、Стол: импортный промышленный войлок (черный)

、Разбивочная планка: массив дерева (натуральный цвет)

Примечание: В зависимости от даты поставки и технического усовершенствования компания-производитель оставляет за собой право замены купленных деталей той же марки.

Подробные рабочие шаги

- Функция предварительной стирки;

- Автоматически точное позиционирование для 3-х боковых ступеней DGU или 4-х боковых ступеней IGU;

- Автоматическое заполнение аргоном может устанавливать значение газа и отображать процесс заполнения в режиме онлайн с высокой концентрацией газа.

Технический параметр

- Разрывная планка: 3+1 тип

- Размер стола: 6300*3500 мм

- Толщина стекла: 3-19 мм

- Мощность: 8 кВт

- Высота стола: 900 + 20 мм

Техническое описание

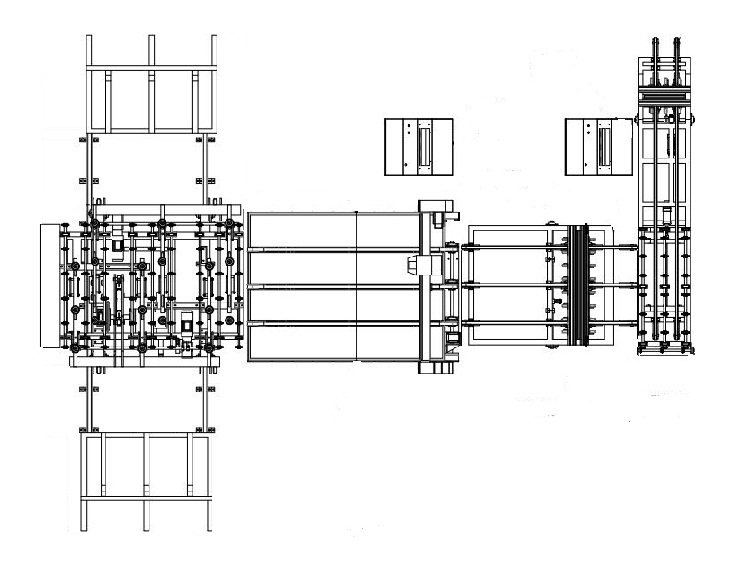

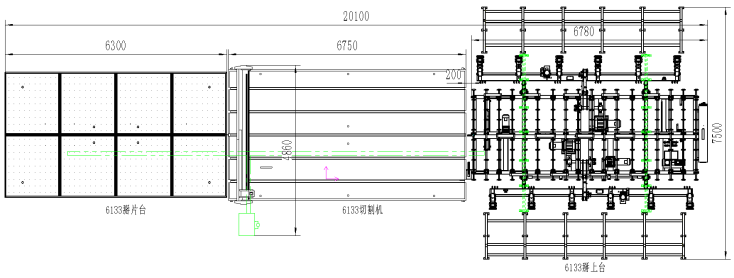

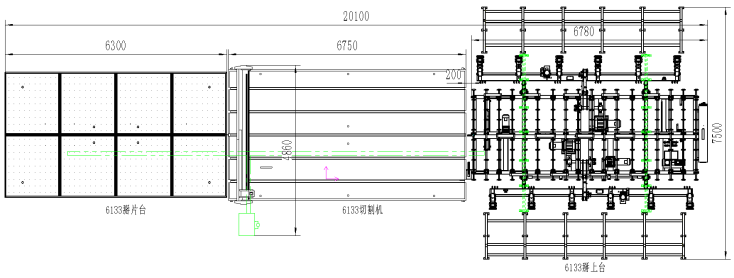

Эскизы дизайна

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой

Автоматическая линия соединения столов для разбивания стекла с воздушной подушкой