LJZW2020 Автоматическая машина для гибки алюминиевых прокладок для стеклопакетов

Автоматическая машина для гибки алюминиевых распорок для стеклопакетов LIJIANG Glass LJZW2020 может автоматически регулировать скорость гибки в соответствии с размером алюминиевой рамы, чтобы избежать деформации большой рамы и обеспечить высокую скорость и непрерывность маленькой рамы, а также это оборудование может поддержка дугообразной алюминиевой рамы и изгиб алюминиевой рамы специальной формы...

- Поставщик: LIJIANG Стекло

- Доставка:

Подробнее

LJZW2020 Automatic Insulating Glass Aluminum Spacer Bar Bending Machine

The angled aluminum frame is one of the reasons for the poor sealing of insulating glass;

the main reason for the failure of angled insulating glass in the case of double sealing is usually improper handling of the four corners of the aluminum frame. Affects the sealing effect of insulating glass. With the improvement of corporate quality awareness and market competition, more and more companies are using aluminum strip bending machines to produce overall bent aluminum frames. In addition to fully automating the aluminum strip bending machine, glass deep processing practitioners use computers to input the shape, input size, input production quantity, input glue amount, etc. to the aluminum strip bending machine, as well as realize functions such as automatic splicing of aluminum strips, and innovate aluminum strips. The use functions of the bending machine are also placed in front of aluminum strip bending machine manufacturers.

It can be realized by bending the whole aluminum strip;

1. Install an argon gas filling hole on the aluminum strip bending machine.

Filling the insulating glass with argon gas is necessary for insulating glass buildings to save energy, reduce noise, lower the dew point, prevent the deformation of the insulating glass from causing the two pieces of glass to stick together, and prevent the oxidation of Low-E glass. As the number of companies that directly inflate air on insulating glass lines increases, the demand for companies that inflate air on aluminum frames is also increasing. This function can be added to the newly developed aluminum strip bending machine. Using an aluminum strip bending machine to drill air holes greatly improves the efficiency of drilling holes in the aluminum frame.

2. Add the digital dimensioning function to the aluminum strip bending machine.

Nowadays, insulating glass production continues to be concentrated in large-scale insulating glass production enterprises. In large-scale production enterprises, insulating glass aluminum frames with similar sizes are prone to confusion when making insulating glass, and the accurate size cannot be found. As a result, the company's production is chaotic and quality is difficult to guarantee. When the aluminum strip bending machine bends the aluminum frame, printing the size and production date of the aluminum frame on the aluminum frame can avoid such problems and improve production efficiency. In addition, to completely solve the problem of aluminum strips affecting the sealing of insulating glass, special equipment for molecular sieve filling and aluminum strips is needed.

2. Introduction to supporting equipment for fully foldable aluminum frames.

Fully folded aluminum frame equipment includes a semi-automatic molecular sieve filling machine, automatic molecular sieve filling machine, semi-automatic aluminum strip bending machine, and fully automatic aluminum strip bending machine. The semi-automatic molecular sieve filling machine can punch the molecular sieve filling holes and fill the molecular sieve. In addition to flushing and filling molecular sieve holes, the fully automatic molecular sieve-filling machine can also automatically seal the molecular sieve-filling holes with glue. A semi-automatic aluminum strip bending machine can fold aluminum strips into rectangular shapes. In addition to folding aluminum bars into rectangles, the fully automatic aluminum bar bending machine can also bend aluminum bars into circular arcs and other arbitrary shapes.

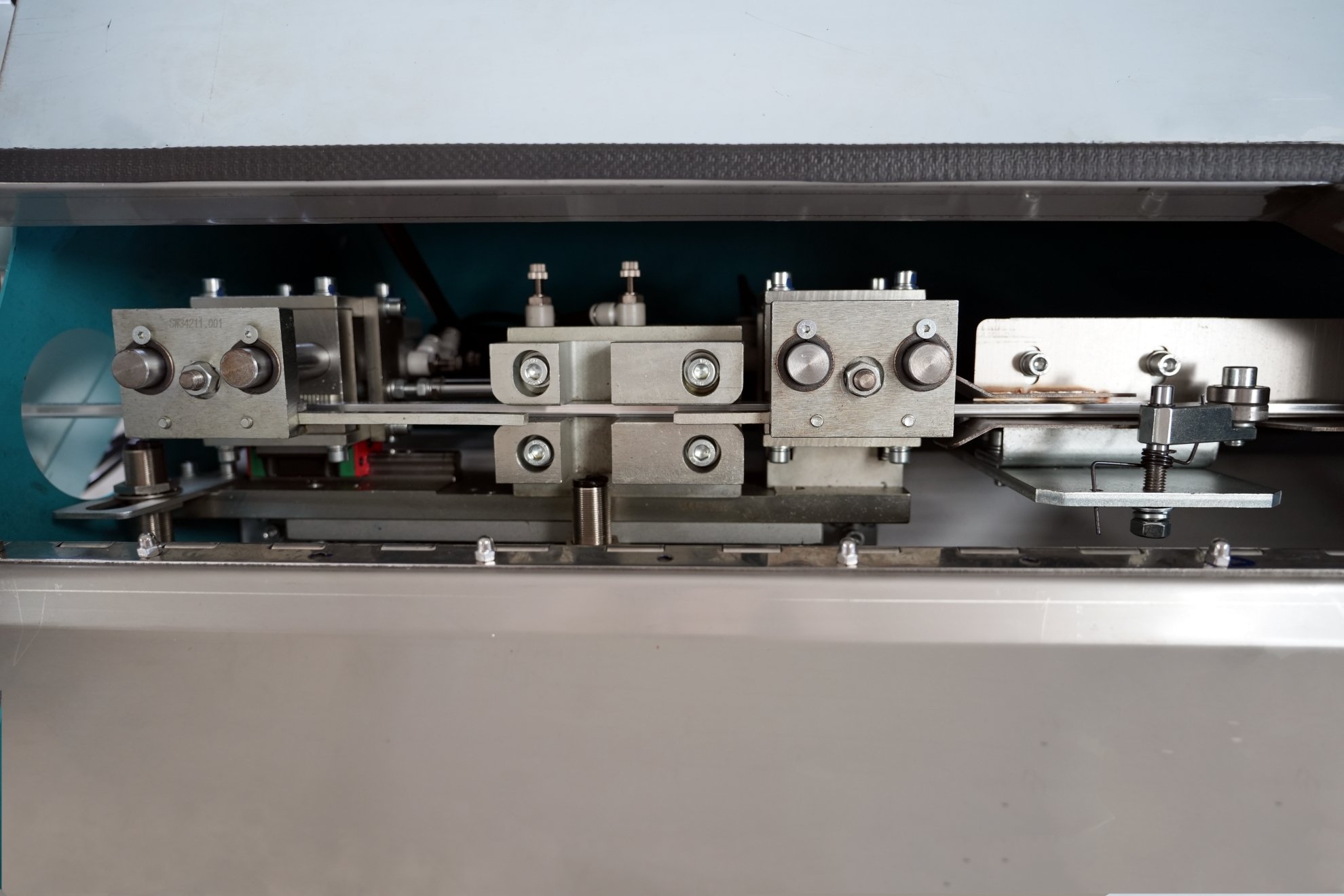

Figure 1 Automatic Insulating Glass Aluminum Spacer Bar Bending Machine 1

Figure 1 Automatic Insulating Glass Aluminum Spacer Bar Bending Machine 1

Benefits & Advantages

- Germany Siemens PLC control system

- Germany Siemens CNC servo control system

- Four spacer size storage units

- CNC servo control feeding mechanism

- Auto furnishing and cutting spacer fuction

- Auxiliary function of adjustment for bending Large aluminum frame

- Can be optional to different specifications and sizes of aluminum space

- Supporting bending for different shapes’ spacers Continuously

- Separated guard board outside of bender

- Automatically avoid the connection while bending and cutting

- Pause/set device, convenient for machine malfunction maintenance, protect the servo motor

- USB input function, read the excel format file directly etc(optional)

- Spacer printing function(Optional)

- Can bend aluminum spacer, Technoform, Alupro, Thermix, Swisspacer and Stainless steel(Stainless steel optional)

- Automatic drill gass filling hole(Optional)

Figure 2 Automatic Saw Cutting Function of Spacer Strips Bending Machine

Figure 2 Automatic Saw Cutting Function of Spacer Strips Bending Machine

Technical Data

| Item. | Spec. |

| Dimension | 10500mm*2200mm*2600mm |

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | 0-47m/min |

| Air pressure | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5Kw |

| Weight | 1800kg |

| Production capacity | 90m/min |

Operating Procedures

- Check whether the equipment and working area are cleaned and wiped clean; there should be no obstacles, impurities, new pulls, grinding, or bruises on the equipment bed, work surface, guide rails, and other main sliding surfaces. If any of the above situations occur, the equipment must be cleared and the equipment must be wiped clean; if new pulls, grinding, or bruises occur, the person in charge of the equipment or the team leader should be asked to check together and make a record.

- Check that the handles, valves, and major components of each operating mechanism should be placed in non-working positions.

- Check that all safety protection devices (protective cover, limit switch, limit stop iron, electrical grounding, safety device, etc.) are complete and intact, and installed correctly and reliably; the door covers of distribution boxes and oil pools should be closed.

- Check that the amount of oil in the lubrication parts (oil pool, oil cup guide rail, and other sliding surfaces) is sufficient, and add oil according to the lubrication instruction chart.

- Check whether the main components and fasteners are abnormally loose. Aluminum bar bending machine operating procedures

- Carry out a dry running test run, start with inching, and check that each operating device, safety device (braking, reversing, interlocking, limit, insurance, etc.) and each indicating device (indicating instrument, indicator light, etc.) should work sensitively, accurate and reliable; the movements of all parts should be coordinated; the oil supply should be normal and the lubrication should be good; the machine tool should operate without abnormal sounds, vibrations, temperature rises, odors, smoke, etc. Make sure everything is normal before starting work.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Какова скорость гибки станка для гибки алюминиевых полос и какое самое быстрое время для изготовления алюминиевой рамы размером 1 м * 1 м?

Как решить проблему сверхшироких углов в процессе гибки композитных полос с теплыми кромками из нержавеющей стали?

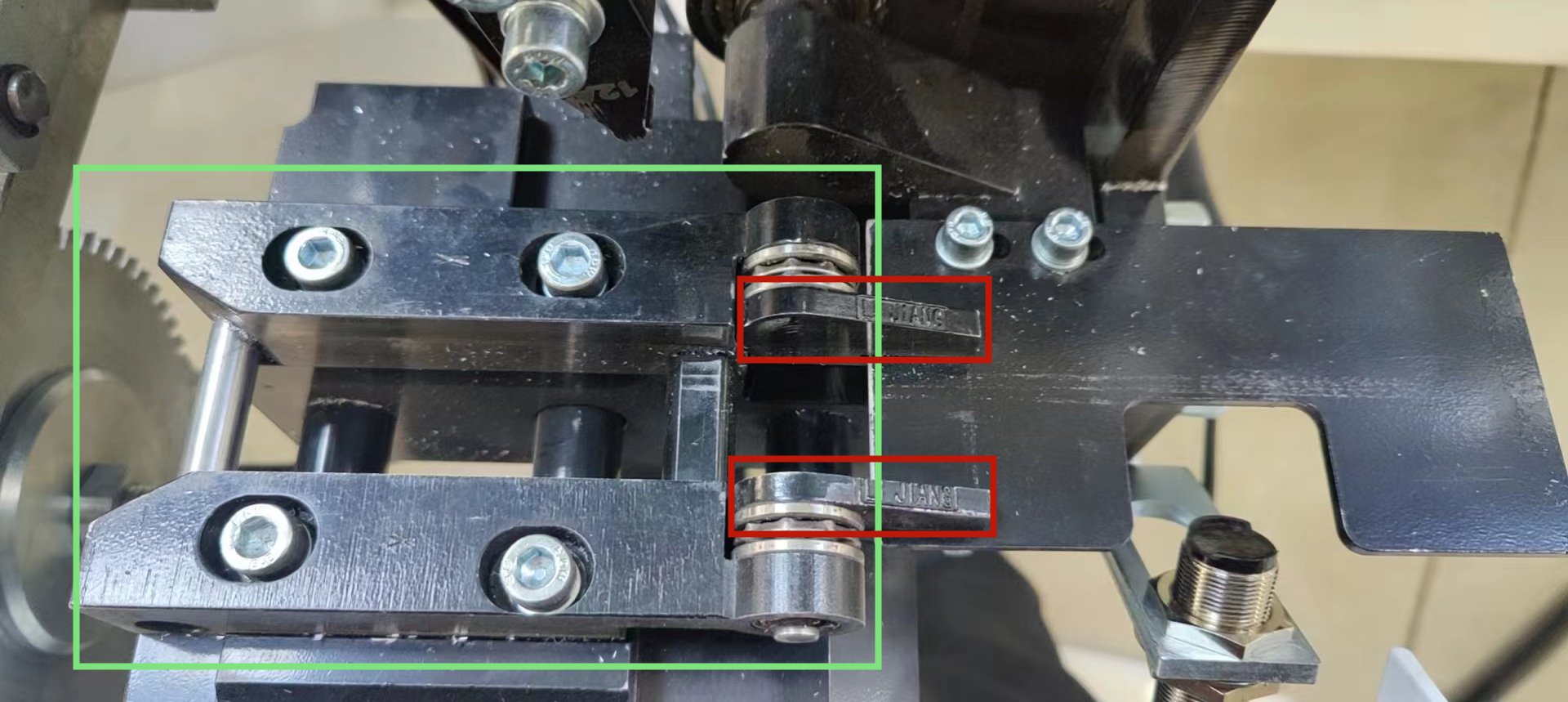

The bending clamp part of the automatic spacer bending machine

The bending clamp part of the automatic spacer bending machine In the production process of insulating glass, stainless steel composite warm edge strips are used more and more as insulating glass spacers. This kind of warm edge strip itself is relatively hard, and the bending angle of stainless steel composite warm edge strips is often encountered during processing. In the case of an ultra-wide section, it is difficult to completely solve the problem simply by increasing the pinch pressure of the spacer bending machine.

LIJIANG Glass can make the bending clamp part of the automatic spacer bending machine into separate parts, which are the red and green parts in the figure, and the red part is the corner part. We can design its plane position to be 10 wires higher than the green fixed part. , which is 0.1mm, this design can increase the force of the bending corner, reduce spring back, and effectively solve the problem of ultra-wide corners.

Как согнуть прокладку из стекловолокна с теплым краем на автоматическом гибочном оборудовании?

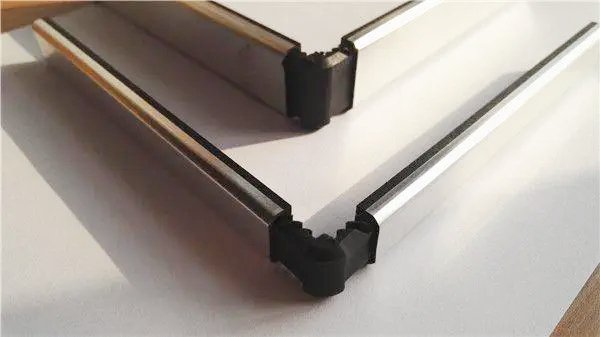

Дистанционная рамка из стекловолокна с теплым краем

Дистанционная рамка из стекловолокна с теплым краемСама прокладка из стекловолокна с теплым краем не содержит металла. Внутренняя сторона теплой кромки содержит материал из стекловолокна, а тыльная сторона представляет собой неметаллическую пленку. Его тепловые характеристики лучше, чем у непроницаемой стальной композитной теплой кромки и чистой непроницаемой стали. Его превосходная степень прямолинейности и степень прочности гарантируют, что две глубины клея между тремя слоями стекла равномерны, а прокладка более прямая и красивая; недостатком является то, что материал из стекловолокна обычно относительно хрупок. Гибка теплых кромок из стекловолокна на обычных гибочных машинах приведет к прямой поломке теплых кромок из стекловолокна. Его нужно нагреть и согнуть, а затем охладить и придать ему форму, прежде чем его можно будет использовать.

Как согнуть полосы из чистой непрозрачной стали с помощью автоматического гибочного оборудования?

Чистые непрозрачные стальные полосы

Чистые непрозрачные стальные полосыВ качестве жесткой прокладки с теплым краем полоса из чистой непрозрачной стали обладает более слабым энергосберегающим эффектом, чем композитная лента с теплым краем из нержавеющей стали и лента с теплым краем из стекловолокна, но она имеет очевидные преимущества при использовании огнеупорного изоляционного стекла или большой пластины. стекла, что выдвигает новые требования к дистанционно-гибочному станку. Из-за высокой твердости непроницаемой стали обычным гибочным машинам трудно формировать ее за один раз, поэтому необходимо согнуть прокладку из чистой непроницаемой стали несколькими методами гибки в соответствии с различным выбором материалов из непроницаемой стали.

Текущее оборудование имеет несколько желобов, как распределяются желоба?

В настоящее время автоматический станок для гибки алюминиевых прокладок для стеклопакетов имеет 4 желоба, которые обычно можно разделить на четыре распределения: 6, 9, 12 и 12-27. В самый широкий можно складывать алюминиевые полосы 27А, а в самый узкий можно складывать алюминиевые полосы 6А.