Equipamento de corte automático de vidro

Escolher a máquina de corte de vidro automática certa é uma das decisões mais importantes para qualquer fabricante de vidro. Com tantas opções no mercado — cada uma prometendo precisão, velocidade e desempenho — pode ser difícil identificar qual equipamento realmente atende às suas necessidades de produção. Neste guia, vamos apresentar os principais fatores e quatro etapas comprovadas para ajudá-lo a comprar o melhor equipamento de corte de vidro para sua oficina ou fábrica.

Princípio Básico de Funcionamento

É usado principalmente para carregamento automático de vidro. Depois de colocar o vidro na posição designada e dar o sinal de carregamento, o braço grande gira cerca de 95 graus por meio do mecanismo de tombamento e toda a máquina começa a se mover para frente. Quando o dispositivo de indução no braço pequeno toca o vidro, toda a máquina para de andar e o vidro é sugado pela ventosa através do sistema de vácuo no vidro, o motor de elevação do braço pequeno levanta o vidro para cima e para trás cerca de 80 mm. O motor ambulante recua e o braço grande cai. Quando o braço de trazer está no lugar, a ventosa sob o vidro começa a soprar. Quando o braço pequeno cai, o vidro cai na roda do transportador. Finalmente, o vidro é transportado para a mesa de corte pela roda transportadora.

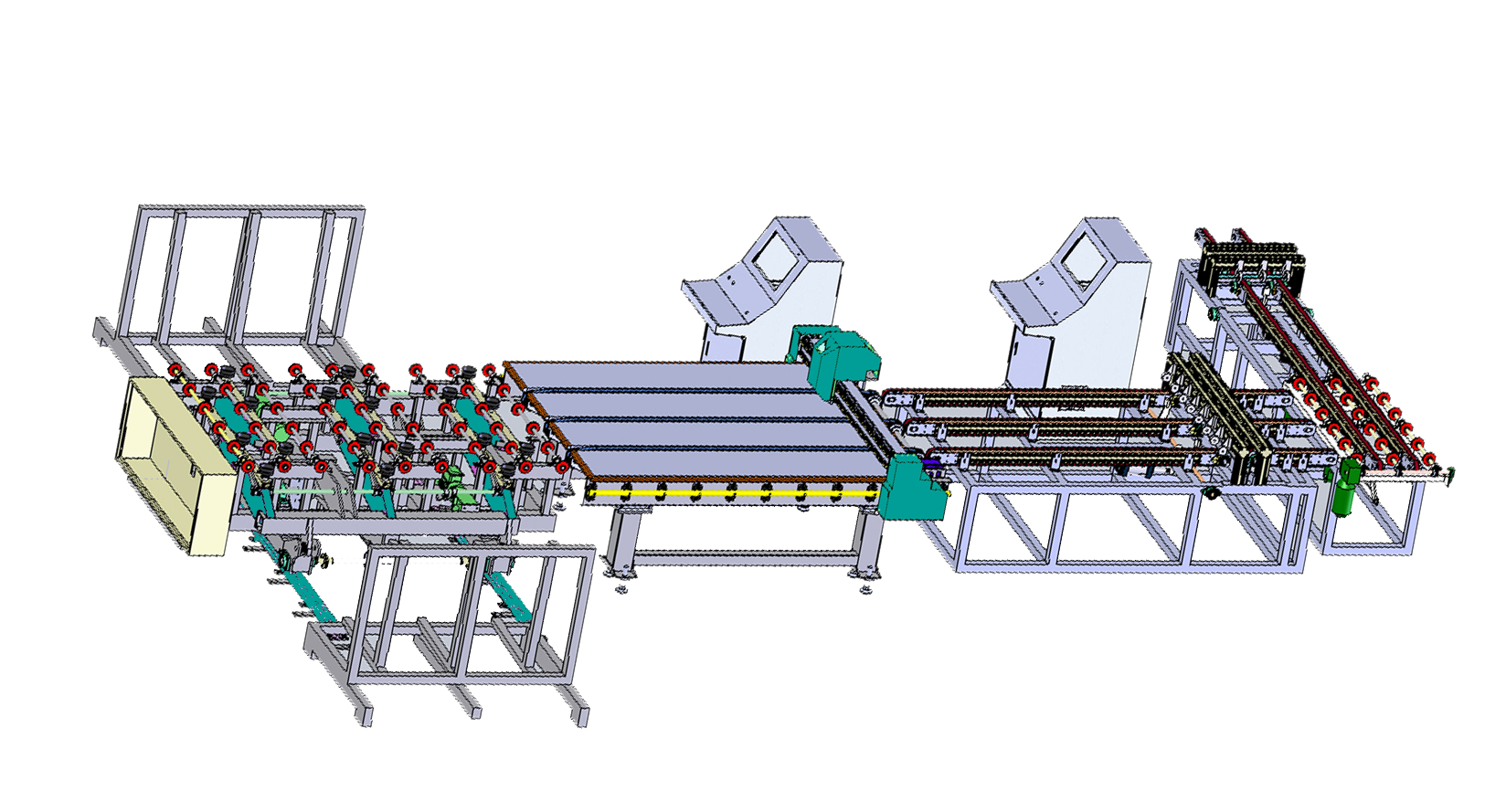

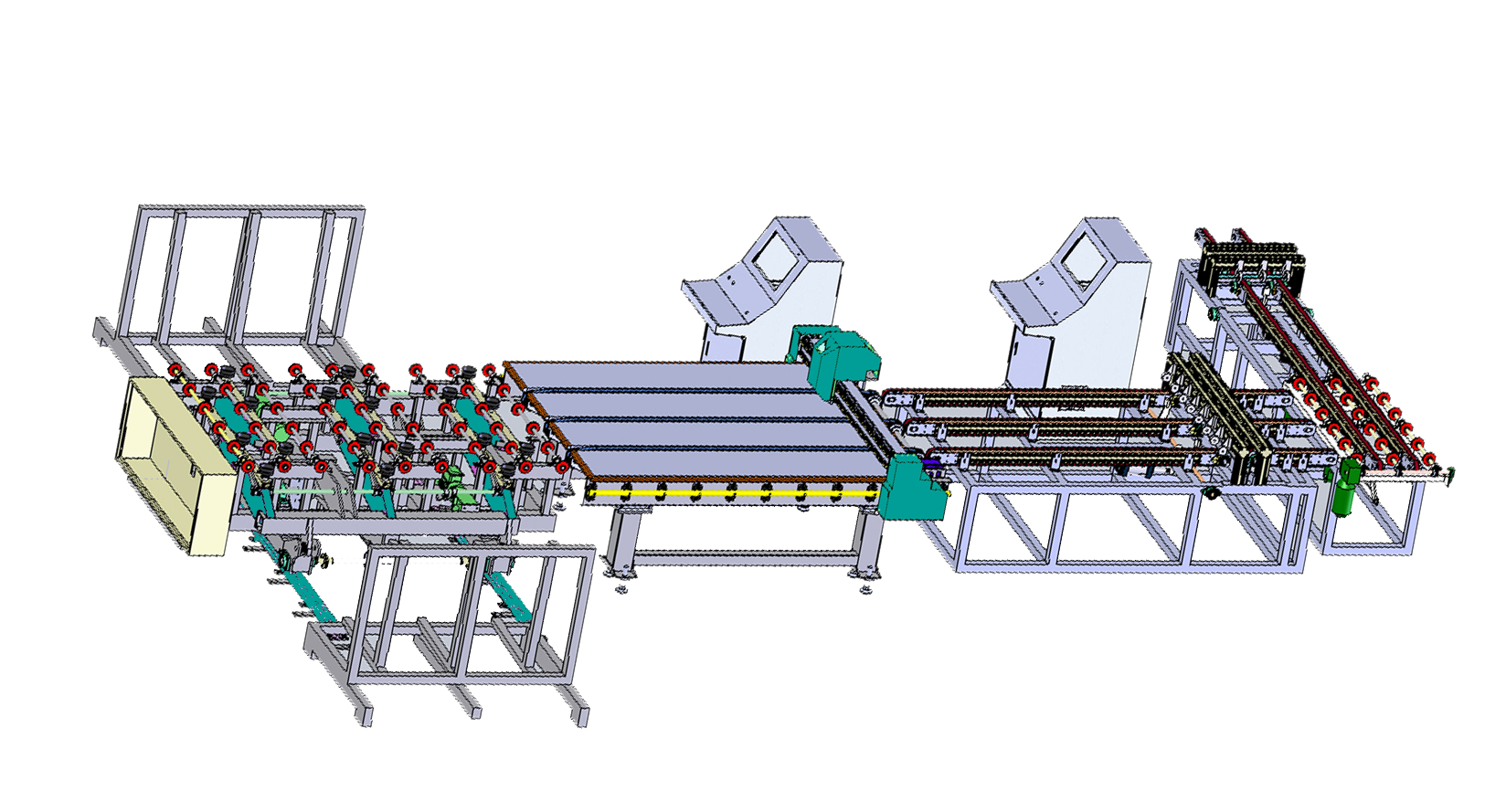

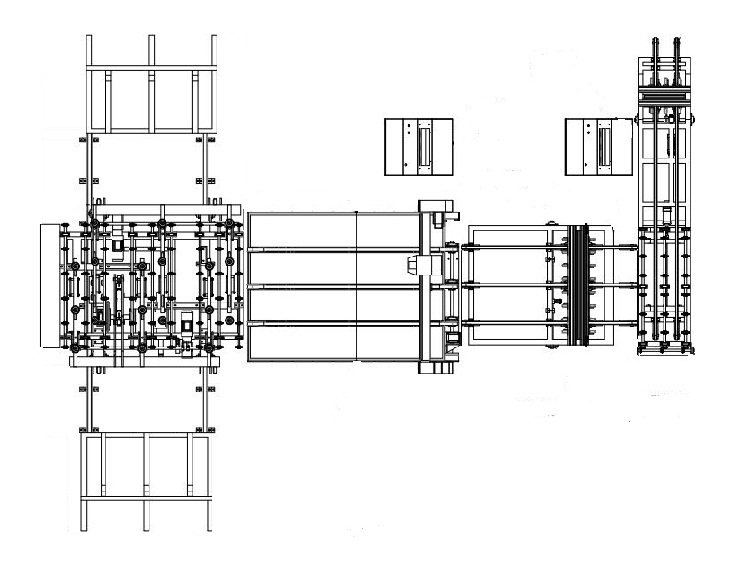

Alimentação de vidro totalmente automática, cortando e quebrando a linha de conexão

Alimentação de vidro totalmente automática, cortando e quebrando a linha de conexão

Alimentação de vidro totalmente automática, cortando e quebrando a linha de conexão

Alimentação de vidro totalmente automática, cortando e quebrando a linha de conexão Etapas de trabalho detalhadas

The whole working process can be accomplished by PLC automatic control or manual control. The manual mode is mainly suitable for equipment adjustment and maintenance.

Each action can be completed independently or can be used for normal work.After giving the loading signal (manual and automatic), the arm turns upward about 95 degrees through the overturning mechanism, and the whole machine starts to move forward.

When the induction device on the arm touches the glass, the whole machine stops walking.The vacuum system works, the glass is sucked by the sucker through vacuum systems. When the vacuum pressure reaches the set pressure, the vacuum pump stops. The sucker's telescopic connecting rod mechanism lifts the glass back and up 80 mm through the arm-lifting motor.

Stopping for about 1.5 seconds to make sure the glass is sucked up, the big arm driven by a motor to reverse the glass to the transmission roller. The suction cup under the glass begins to blow, and the telescopic connecting rod mechanism makes the suction cup and the glass fall at the same time.

When the glass falls on the conveyor roller, the small arm continues to fall, the glass is separated from the suction cup, and the conveyor starts to send the glass sheet to the front end of the loading machine and stop at the signal point.Then the whole frame moves automatically to find the zero position and stops.

Waiting for the signal from the cutting table, the glass can be sent to the cutting table at the same speed as the conveyor belt on the cutting machine. After the glass is sent out,automatically repeat the work cycle. The machine can select any position according to the required glass thickness.

Each action can be completed independently or can be used for normal work.After giving the loading signal (manual and automatic), the arm turns upward about 95 degrees through the overturning mechanism, and the whole machine starts to move forward.

When the induction device on the arm touches the glass, the whole machine stops walking.The vacuum system works, the glass is sucked by the sucker through vacuum systems. When the vacuum pressure reaches the set pressure, the vacuum pump stops. The sucker's telescopic connecting rod mechanism lifts the glass back and up 80 mm through the arm-lifting motor.

Stopping for about 1.5 seconds to make sure the glass is sucked up, the big arm driven by a motor to reverse the glass to the transmission roller. The suction cup under the glass begins to blow, and the telescopic connecting rod mechanism makes the suction cup and the glass fall at the same time.

When the glass falls on the conveyor roller, the small arm continues to fall, the glass is separated from the suction cup, and the conveyor starts to send the glass sheet to the front end of the loading machine and stop at the signal point.Then the whole frame moves automatically to find the zero position and stops.

Waiting for the signal from the cutting table, the glass can be sent to the cutting table at the same speed as the conveyor belt on the cutting machine. After the glass is sent out,automatically repeat the work cycle. The machine can select any position according to the required glass thickness.

Parâmetro técnico

- Tamanho da folha: Tamanho mínimo: 2400*1500 mm (carregamento de um lado)

- Tamanho máximo de carregamento: 6100*3300 mm

- Espessura da folha de vidro: 3 ~ 19 mm

- Profundidade de absorção de trabalho: 700 mm

- Velocidade de caminhada no eixo X: 5-25 m/min (ajustável)

- Velocidade de caminhada do eixo Y: 8-12 m/min (ajustável)

- Velocidade de transporte: 5-25 m/min (ajustável)

- Número de braços flip: 12 braços (carga lateral dupla)

- Número de ventosas de braço único: Três

- Tipo de carregamento: carregamento lateral duplo

- Ciclo de trabalho: 60 S (30 S para cada posição adicional)

- Fonte de alimentação de instalação: AC 380V/50Hz (circunstâncias especiais podem ser ajustadas de acordo com os requisitos do cliente)

- Potência total de instalação: 8-17 kw

- Ar comprimido: 0,6-0,8 Mpa;

- Vácuo: -50-99 Kpa (ajustável de acordo com a espessura do vidro)

- Altura da mesa de trabalho: 900 + 20 mm

- Tamanho da máquina: 4650*2980*900 milímetros

Descrição técnica

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

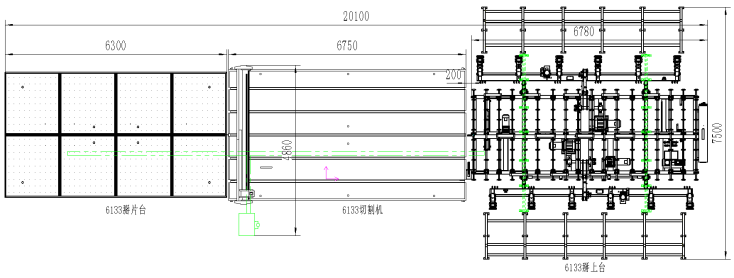

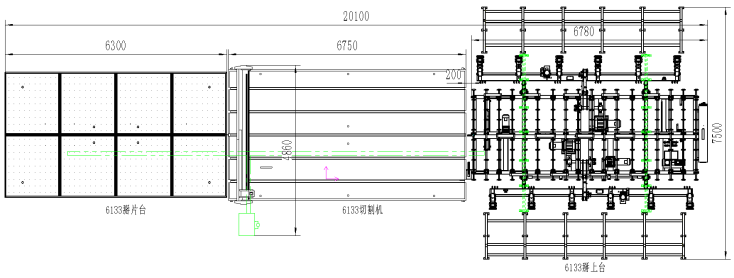

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line Princípio Básico de Funcionamento

It's working principle is to convey the cut glass by conveying belt to worktable, automatically input the position of glass through photoelectric scanning system, and then the cutting head with diamond wheel on the cutter holder moves along X and Y directions respectively by program control, cuc the sheet. CNC motion controller is used in the control part of the machine, and advanced AC servo motor is used in the drive part.

Etapas de trabalho detalhadas

- The chassis material is welded and formed by the national standard manganese-containing section bridge steel (Q345A) after aging treatment. The comprehensive mechanical properties, plasticity and welding properties of this kind of steel are good. The frame is processed as a whole, and the stability and accuracy of the equipment are greatly improved by tempering aging treatment to ensure the stability of the product. After special rust removal process, the surface rust spots and oxide layer are removed. The top coat is sprayed with high-grade epoxy primer and the top coat is sprayed with high-grade automobile paint.

- Through the analysis of professional structure software, the equipment ensures the stability, dynamic balance, mechanical strength to achieve the most perfect match, and ensures that the structure of the table is not deformed.

- The device has one key reset function. It can complete all the preparations before starting automatically by clicking on the touch screen, which greatly improves the work efficiency.

- Reasonable arrangement of integral cables and gas pipes and complete sealing

- High-speed silent linear guide is adopted for guide rail, which has high cutting accuracy and low noise.

- Advanced Japanese Ankawa servo motor is used in the driving part, which makes the equipment reliable, error small and efficient.

- Japanese SMC proportional solenoid valve is used for cutting rice. The pressure is automatically adjusted according to the glass thickness. The cutter head rotates 360 degrees, and the upper and lower buffering cutter cuts (any straight line and all kinds of special shaped glass can be cut accurately).

- The knife head is equipped with knife protection function. If the knife head falls outside the glass or the glass gap, the program stops automatically, effectively preventing damage to parts and glass.

- Double motor high speed drive (large inertia Yaskawa servo) ensures cutting speed and fluency;

- Conveyor device, synchronous automatic transmission device, convenient for glass upper and lower transmission, frequency conversion speed regulation, stable and easy to optimize the transmission speed;

- Positioning device, photoelectric scanning positioning system;

- Compensation function, tool eccentricity compensation, clearance compensation, pitch compensation.

Parâmetro técnico

- Max size: 6100×3300 mm

- Thickness: 3~19 mm

- Cutting accuracy: ±0.30

- Cutting accuracy of special-shaped glass: ±0.35

- Cutting speed: 0-200 m/min

- Conveying speed: 0-25 m/min

- Machine size:6800×4100×1500 mm

- Working table height: 900 mm±20 mm

- Weight: 2600 kg

- Total power of equipment:9-15 kw

Descrição técnica

Software part:

Motion Controller:

Optimization software:

Motion Controller:

- Fast running speed, smooth running, high control accuracy, modular controller structure;

- The man-machine interface is simple and generous, the parameter adjustment is simple, the parameters that need to be modified by operators are less, simple and intuitive, and the requirements for operators are low.

- Pipeline cutting mode, photoelectric positioning cutting mode and direct cutting mode are set freely through options. The automatic cutting mode and air operation mode can be switched at any time during the processing.

- Graphic library nesting programming, select special-shaped from the library, set relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

- Complete storage of glass pressure stock, once the cutting pressure of each specification thickness is input and saved, it can be directly invoked;

- Real-time tracking and displaying of processing path, timely recording of motion coordinates, axis state, I/0 state, automatic recording of fault diagnosis and alarm;

- Receive a variety of processing documents, accept the standard G code of Optima, Super Package Software, AUTOCAD DXF file, the system has its own graphics editing software (exactly the same as Paul's editing method);

- Graphic library nesting programming, selecting abnormal shape from the library, setting relevant parameters, processing quantity, automatic nesting, generating processing trajectory;

- The sorting function of DXF class files, including the nearest point, entry point, or by graphics color clockwise, counterclockwise sorting and other options. Free the switch between single-phase cutting and bidirectional cutting is realized.

- Photoelectric positioning function, according to the actual position and deflection angle, automatically adjust cutting;

- Compensation function: tool eccentricity compensation, clearance compensation, pitch compensation;

- All kinds of protection: including soft and hard limit, cutter pressure limit, external emergency stop control and so on.

Optimization software:

- Importable optimization results done in the Office

- Cutting scheme can be manually created and edited

- With copy and mobile functions

- Manual editing of cutting sequence

- The cutting scheme can be quickly created by X, Y and Z modes.

- Simultaneous optimization of multiple original and small patches

- Optimized typesetting without size limitation

- Optimized Result Rotation, Mirror Management, etc.

- Priority management for small size cutting optimization

- Priority management of original glass sheet optimization

- Template Scanning Function and Scanning Graphics Processing

- Original glass sheet storage Management

- 20 efficient optimization algorithms

- Cutting graphics can be edited

- Label Design and Label Printing(Label-WAY)

- Clear Printing of Optimized Result Report

- Excel Data File Import

- Low-E Glass and Adhesive Glass Cutting Management

- A graphics library containing 350 parametric graphics, including all the commonly used graphics types (Geo-Way)

- Two-Dimensional CAD System with Abnormal Scanning Processing Function (Cad-Way)

- Automatically converting digital signals from CNC systems into graphical forming points

- There are many language choices for the software operation interface, including the Chinese interface.

- Follow up the latest international software development, provide upgraded versions in real time, and achieve the latest functional requirements for customers

Princípio Básico de Funcionamento

Parte elétrica:

、Contadores: Renmin/Zhengtai

、Disjuntor: Renmin/Zhengtai

、Botão: Renmin/Zhengtai

、Válvula solenóide principal: Airtac

、Outros componentes pneumáticos: Deke/Shengguan

、Fã: Liyuan

Parte mecânica;

、Mesa de trabalho: placa de alta densidade à prova d'água

、Tabela: feltro industrial importado (preto)

、Barra de quebra: madeira maciça (cor natural)

Nota: Em função da data de entrega e do aperfeiçoamento técnico, a produtora reserva-se o direito de substituir as peças adquiridas da mesma marca.

、Contadores: Renmin/Zhengtai

、Disjuntor: Renmin/Zhengtai

、Botão: Renmin/Zhengtai

、Válvula solenóide principal: Airtac

、Outros componentes pneumáticos: Deke/Shengguan

、Fã: Liyuan

Parte mecânica;

、Mesa de trabalho: placa de alta densidade à prova d'água

、Tabela: feltro industrial importado (preto)

、Barra de quebra: madeira maciça (cor natural)

Nota: Em função da data de entrega e do aperfeiçoamento técnico, a produtora reserva-se o direito de substituir as peças adquiridas da mesma marca.

Etapas de trabalho detalhadas

- Função de pré-lavagem;

- Posicionamento preciso automaticamente para 3 DGUs de passo lateral ou 4 IGUs de passo lateral;

- O enchimento automático de gás argônio pode definir o valor do gás e exibir o processo de arquivamento on-line com alta concentração de gás.

Parâmetro técnico

- Barra de quebra: tipo 3+1

- Tamanho da mesa: 6300*3500 mm

- Espessura do vidro: 3-19 mm

- Potência: 8kw

- Altura da mesa: 900 + 20 mm

Descrição técnica

Esboços de design

Linha de conexão automática da mesa de quebra de vidro flutuante a ar

Linha de conexão automática da mesa de quebra de vidro flutuante a ar

Linha de conexão automática da mesa de quebra de vidro flutuante a ar

Linha de conexão automática da mesa de quebra de vidro flutuante a ar