La diferencia entre el tamiz molecular tipo A y el desecante tipo B para vidrio aislante.

As we all know, the air mainly contains nitrogen, oxygen, carbon dioxide, and some rare gases and other gases and impurities. Among them, nitrogen (N2) accounts for about 78%, oxygen (O2) accounts for about 21%, and the remaining 1% contains about 0.03% Carbon dioxide (CO2), about 0.94% rare gases (such as argon Ar, krypton Kr, xenon Xe, helium He, neon Ne, radon Rn, etc.); other gases and impurities account for about 0.03%, such as ozone O3, nitric oxide NO, nitrogen dioxide NO2, water vapor H2O, etc.

The molecular diameters of some common gases are: He (helium) 0.26nm, H2 (hydrogen) 0.289nm, CO2 (carbon dioxide) 0.33nm, Ar (argon) 0.34nm, O2 (oxygen) 0.346nm, N2 (nitrogen) 0.364nm, CO (carbon monoxide) 0.376nm, CH4 (methane) 0.38nm, HCHO (formaldehyde) 0.45nm.

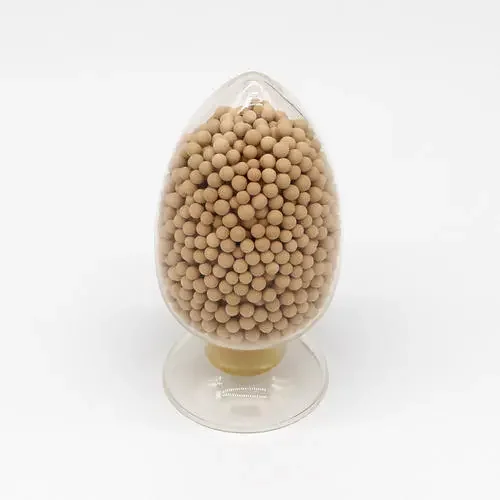

Figure 1 The 3A molecular sieve for insulating glass

When the 3A molecular sieve is in contact with air, it only absorbs the gaseous water molecules in the air and does not absorb other components in the air. It is the most ideal drying material for insulating glass.

What is a 3A molecular sieve for insulating glass

A molecular sieve (also known as synthetic zeolite) is a kind of aluminosilicate microporous net-like crystal material, composed of SiO2 and Al2O3 tetrahedrons, with uniform pore size (about a few angstroms) and a huge specific surface area. There are metal cations (such as Na+, K+, Ca2+, etc.) in the molecular sieve lattice to balance the excess negative charges in the tetrahedron. Different types of molecular sieves have different pore sizes or shapes and can be used to separate various molecules. Water is a very polar molecule. Type A molecular sieve has a very high affinity with water, and is often used as an excellent adsorbent.

The lattice pores of the 3A type special molecular sieve for insulating glass is about 3 angstroms (1?=0.1nm), which is the smallest pore among the commonly used molecular sieves. When it is in contact with air, it can only absorb gaseous water molecules in the air, but not Other components in the air (the content of helium and hydrogen in the air only accounts for about 0.007%, which can be ignored). Any other molecular sieve with an adsorption pore size larger than 3A will adsorb oxygen, nitrogen, and other gases in the air, and this adsorption capacity will be very sensitive due to small changes in temperature.

There are several common specifications of 3A molecular sieves used for insulating glass on the market:

1) The machine is used for molecular sieves filling and aluminum spacer strips bending with a diameter of 0.5-0.9mm;

2) 1.5-2.0mm diameter products for manual molecular sieves filling and aluminum spacer strips dismantling;

3) Other diameters: 1.0-1.5mm; 1.3-1.8mm; 1.8-2.2mm; 2.0-2.5mm, etc.

Figure 2 The several common specifications of 3A molecular sieves used for insulating glass

Desiccant other than 3A molecular sieve

At present, some insulating glass manufacturers on the market do not use 3A molecular sieves, some use 4A molecular sieves, and some use type B desiccants.

4A molecular sieve lattice pores are about 4 angstroms. Although 4A has a strong adsorption capacity for water, it will also absorb part of the nitrogen and other inert gases in the air, and as the ambient temperature rises and falls, it will adsorb and absorb nitrogen. Desorption: When the temperature decreases slightly, the 4A molecular sieve will adsorb the air in the insulating glass, resulting in a vacuum state; when the temperature rises, the 4A molecular sieve releases the air into the insulating glass spacer layer, causing the air in the insulating glass to expand. With the change of temperature difference between day and night and the change of seasons, insulating glass is easily distorted and broken due to expansion and contraction, and its life is shortened; sudden breaking of insulating glass may cause major safety accidents. Therefore, using a non-3A molecular sieve as a drying agent for insulating glass is strictly forbidden.

The definition of Class B desiccant in the industry standard is a spherical desiccant made of attapulgite as the main material. The author analyzes and believes that the common type B desiccants currently on the market are divided into 4 types: a. It is made of only roasted or unfired clay, with poor drying power, low adsorption capacity, low-temperature rise, and high dew point; b. plus Zeolite powder is used as a mineral raw material. Zeolite is mainly used in detergents and has a certain temperature rise, but the dew point control is very poor, the lowest is -30℃, and the service life is short; c. It is made of calcium chloride and clay, and the temperature rise is better.

The pore size of type B desiccant is generally about 20 angstroms. In addition to adsorbing moisture in the air, it also adsorbs most inert gases such as oxygen, nitrogen and carbon dioxide; when the ambient temperature rises, the desiccant releases the adsorbed nitrogen and oxygen gases, Causing the internal pressure of the insulating glass to be stronger than the outside pressure, the insulating glass will be convex; when the ambient temperature is lowered, the desiccant will adsorb nitrogen, oxygen and other gases into the desiccant cavity, making the external pressure stronger than the internal pressure of the insulating glass, and the convexity disappears or the concave is concave. When the glass reaches the critical point of fatigue under long-term action, the insulating glass will burst, causing great safety hazards.

When the temperature is low or high, the adsorption capacity of the B type desiccant will be very low, which will affect the dew point of the insulating glass and make the insulating glass prone to fogging.

Figure1 The adsorption function of different desiccants

| Desiccant type | Aperture | Adsorbable substance | Non-adsorbent |

| 3A desiccant | 3 | Water | Everything else |

| 4A desiccant | 4 | Water、Nitrogen | Krypton, SF6 solute |

| Type B desiccant | ≥20 | All inert gases | Substances larger than other pores |

| Silica gel or alumina | 200-300 | All | None |

The difference between type A molecular sieve and type B desiccant

Genuine 3A type molecular sieve for insulating glass has a pH value of 8-9, which is weakly alkaline. It will not corrode auxiliary materials for insulating glass such as aluminum spacer strips and sealant. The type B desiccant is mainly processed from attapulgite and calcium chloride. Because calcium chloride is corrosive, it will be strongly alkaline when it meets water, with a pH of 11-13, when it meets water. After the molecules are adsorbed for a period of time, the skin will fall off and corrosive substances will flow out, which will corrode the aluminum strip and the sealant. Another important difference is hydrolysis. Although type B desiccant has a low adsorption capacity, its pore size is large, and the temperature requirement for hydrolysis and absorption is also low. Generally, when the sun is exposed to more than 30-40 degrees Celsius in summer, the type B desiccant will absorb the water in the stomach. When the molecules spit out, the water molecules will adhere to the inner surface of the insulating glass, causing the insulating glass to fog. For type A molecular sieves, the temperature conditions for hydrolysis and absorption generally need to be above 150°C to spit out the water molecules adsorbed in the molecular sieve cavity. This temperature has exceeded the limit of human survival.

Table 2 The comparison of desiccants for insulating glass currently on the market

| Category | Appearance | Energy-saving destruction | Life of insulating glass | Safety impact |

| 3A molecular sieve | No effect | No damage | Life span of more than 20 years | No safety hazard |

| Calcium oxide desiccant | The aluminum bar is corroded with powder, and the glass edge is corroded | The damage is not obvious | The aluminum bar is corroded badly, and the glass life is short | There is a safety hazard |

| Attapulgite desiccant | The aluminum bar is severely corroded, and the glass is crystallized | Destruction of butyl rubber and Low-E glass, condensation | Sealant aging affects the life of glass | The glass falls off, there is a great safety hazard |

The main application areas of type A molecular sieve

3A molecular sieve-drying, dehydration and purification of various liquids (such as ethanol); various air and refrigerants; natural gas, methane gas; unsaturated hydrocarbons and petroleum cracked gas, ethylene, acetylene, propylene, butadiene, etc.

4A molecular sieve-daily chemical detergent; environmental protection-industrial and agricultural, civil water and sewage treatment; water treatment-instead of sulfonated coal, hard water softener; metallurgical industry-separating agent, separation and extraction of potassium and rubidium in brine , Cesium, etc., used in the process of enrichment, separation and extraction of metals; natural gas drying; petrochemical industry-adsorbents, catalysts, desiccants; automotive brake systems and other fields.

5A molecular sieve-main applications: desulfurization and carbon dioxide removal; nitrogen-oxygen separation, nitrogen-hydrogen separation; production of oxygen, nitrogen, and hydrogen; petroleum dewaxing; separation of normal hydrocarbons from branched hydrocarbons and cyclic hydrocarbons.

13X molecular sieve-main applications: gas purification, removal of water and carbon dioxide in air separation devices; drying and desulfurization of natural gas, liquefied petroleum gas, and liquid hydrocarbons; deep drying of general gases.

For more information about LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.