La línea de producción de vidrio aislante súper grande completamente automática pasó con éxito la inspección de aceptación en Foshan.

On January 8, 2022, at Yaobo (Liqing) Glass Technology Co., Ltd., Foshan City, Guangdong Province, China, under the witness of General Manager Mr.Han and General Manager Yaobo Luohan of LIJIANG Glass Automation Equipment Co., Ltd., as well as many glass industry experts and engineers, The fully automatic super-large insulating glass production line produced by LIJIANG Glass successfully passed the acceptance inspection in Foshan and was officially put into production.

The whole process of this type of insulating glass production line produced by LIJIANG Glass is highly automated, and the number of posts is small. It has obvious advantages in terms of product specifications and production efficiency. This fully automatic super-large insulating glass production line can not only process two pieces of super-large insulating glass at the same time, which improves the processing efficiency but also adopts the plate pressing technology of German Bystronic. The work has realized the production of super-large insulating glass of 3.3*8 meters. In addition, the proportion of inert gas charged at one time on the 3.3*8 meter ultra-large glass line can reach more than 90%, which makes the filling process of insulating glass more energy-saving and environmentally friendly. Thanks to Mr. Han's team for creating such an excellent machine for us. Liqing Glass will also deeply cultivate the high-end customized market of home improvement doors and windows, continue to strive for progress, and contribute to the Chinese glass industry. "

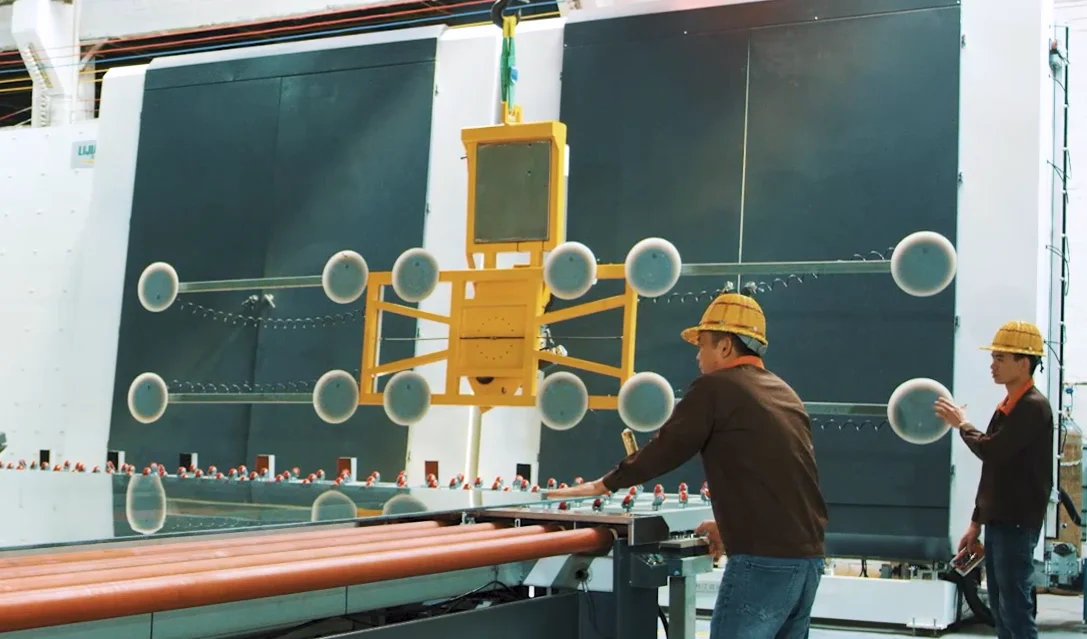

Figure 1 The automatic super-large board insulating glass production line 1

LIJIANG Glass's fully automatic super-large insulating glass production line and the conscientious working attitude of LIJIANG Glass employees have not only been well received by domestic and foreign customers but also highly valued by Jinan Science and Technology Bureau, Industry and Information Bureau, Intellectual Property Office, and Association for Science and Technology. After winning the "High-tech Enterprise", LIJIANG Glass has been successively selected as the "Specialized, Specialized and New" SMEs in Jinan and Shandong Province, and awarded the "Jinan Gazelle Enterprise", "Enterprise Science and Technology Association" and "Jinan Expert Workstation" and won the "Industrial Support". Special funds for development” awards, etc.

Figure 2 The automatic super-large board insulating glass production line 2

LIJIANG Automation Equipment Co., Ltd. has never stopped exploring and innovating. In 2020, the LIJIANG Glass team has positioned itself as the goal of making super-large board hollow lines. By benchmarking against the world's top manufacturers, the person in charge of the LIJIANG Glass Technology Department leads the technology. The team decomposed the super-large board production line with a processing capacity of 8 meters into two plate presses and realized the technical idea of precise and synchronous pressing of servo screws. In the design process, various difficulties were overcome, from solving the load-bearing problem of super-large board glass, inflating Difficulty, glass lifting and adsorption, glass conveying challenges, and other links were overcome one by one, and finally achieved a breakthrough in the fully automatic super-large insulating glass production line. Through the unremitting efforts of the LIJIANG Glass people, this technical achievement obtained the patent for the double-filled double-plate pressing insulating glass production line for insulating glass in May 2021 (patent number: ZL 2021 2 0372439.2). This is not only a breakthrough in Jinan LIJIANG Glass's plate pressing technology but also an affirmation of the automation level of international insulating glass processing equipment technology.

Figure 3 The double-filled double-plate pressing insulating glass production line 1

Chinese high-quality machine, made by LIJIANG Glass. LIIANG Glass will live up to expectations, continue to work hard in the glass deep processing industry, forge ahead, and be a professional and innovative in the glass machinery industry.

For more information about Jinan LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.