Máquina de lavar vidro para venda

Máquina de lavar e secar vidro vertical

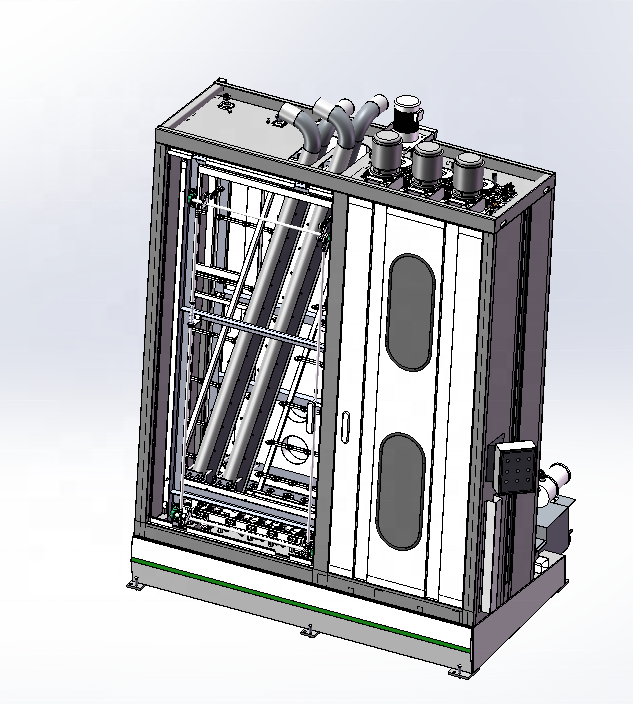

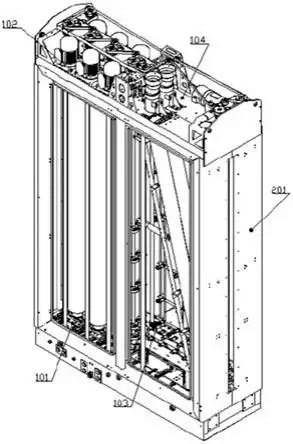

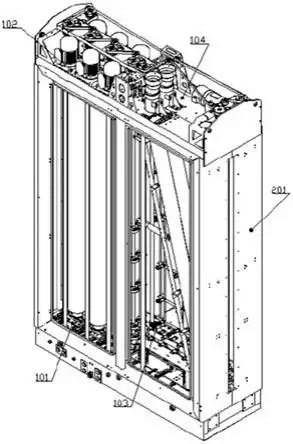

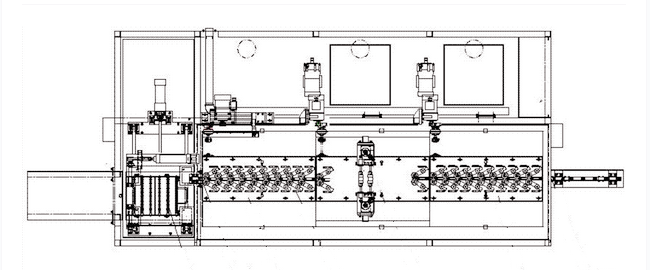

LIJIANG Glass - Tipo: Máquina vertical de lavar e secar vidro LJLQ-2000

Princípio Básico de Funcionamento

The overall structure of the LJLQ-2000 vertical glass washing and drying machine is composed of four sections: inlet section, air-drying section, and outlet section. It is mainly composed of four major mechanisms: conveying, cleaning, strong wind, and inspection. It has the characteristics of strong decontamination ability, cleanliness, and good air-drying effect.

Know More

Know More

Etapas de trabalho detalhadas

Características Estruturais

Saber mais

- O rolo da escova na parte de limpeza é transportado por uma correia independente do motor. A escova é feita de material resistente a ácidos e alta temperatura de alta qualidade, que tem bom efeito de limpeza e longa vida útil.

- Adota sistema de transmissão preciso e regulação de velocidade de conversão de frequência, que pode ser operado diretamente no painel para ajustar a velocidade de limpeza de forma arbitrária.

- Os rolos de borracha de transporte de alta qualidade são densamente arranjados, o que pode processar diferentes tamanhos de vidro. Combinado com transmissão de engrenagem, a transmissão de vidro é mais estável.

- Utilizando um eficiente sistema de limpeza e secagem ao ar, vidros de diferentes espessuras podem ser limpos e secos automaticamente; é limpo com uma escova, seco com um rolo de esponja de alta qualidade e depois seco com ar quente uma vez para garantir que o efeito de limpeza do vidro seja limpo e brilhante, sem deixar vestígios de manchas de limpeza.

Saber mais

Parâmetro técnico

Parâmetros:

Saber mais

- Tamanho máximo do vidro: 2000 mm*2500 mm

- Tamanho mínimo do vidro: 2500 mm*3000 mm

- Direção de trabalho voltada para o equipamento

- Velocidade de lavagem: 2-10 m/min

- Espessura do vidro: 3-15 mm

- Espessura do vidro isolante: ≤40 mm

- Abastecimento de água: 0,5 toneladas/dia de água circulante, condutividade ≤40μS

- Velocidade de lavagem: 2-10 m/min

- Altura de trabalho: 580 mm

- Potência: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, conforme DIN 40040

- Humidade relativa do ar: ≤ 75%, conforme DIN 40040

Saber mais

Descrição técnica

Máquina de lavar e secar vidro vertical

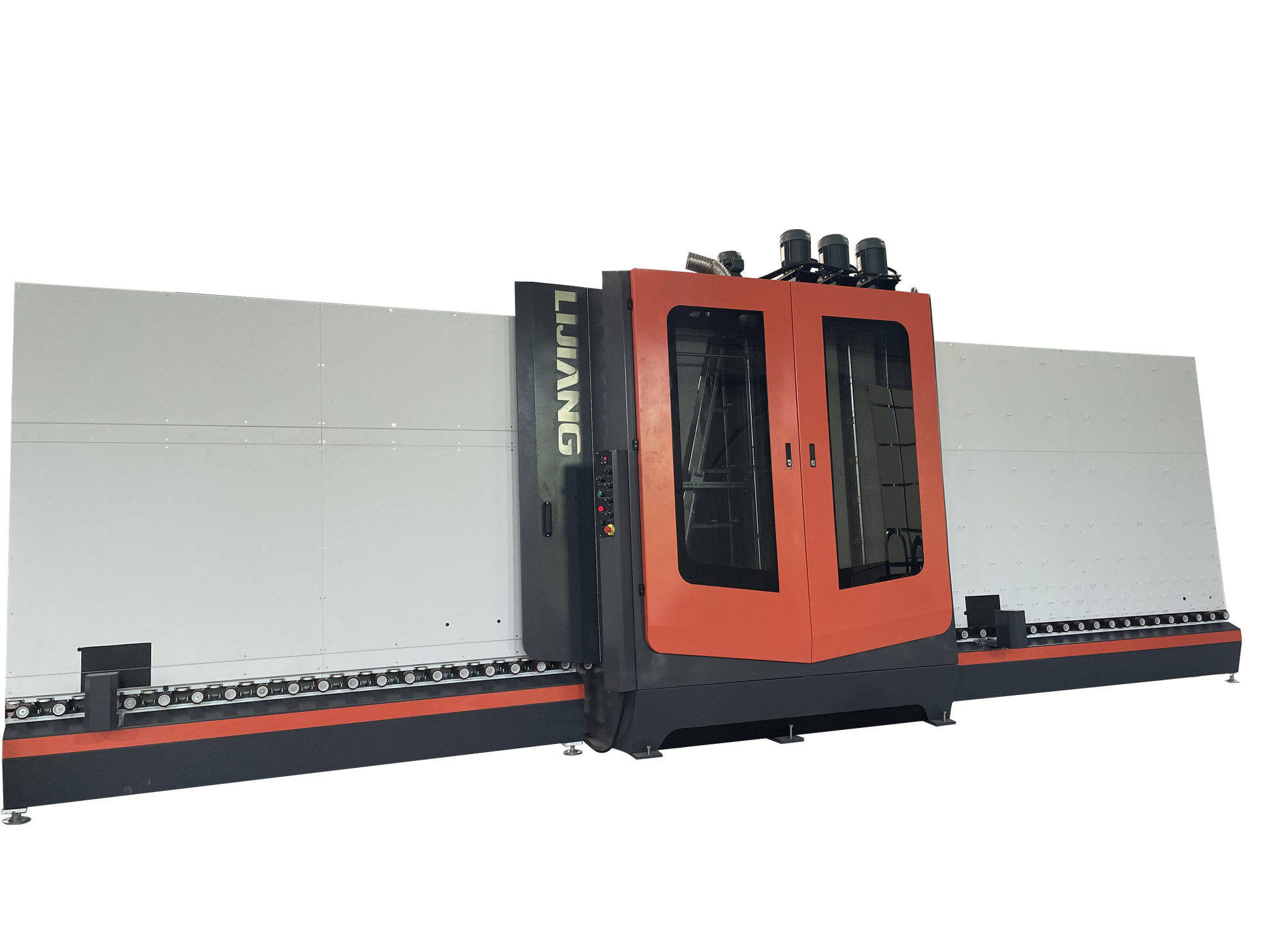

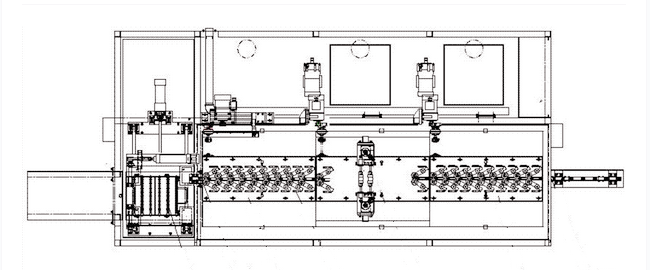

LIJIANG Glass - Tipo: Máquina de lavar e secar vidro vertical LJLQ-2500

Princípio Básico de Funcionamento

LJLQ-2500 glass washing and drying machine could wash max glass of 2500 mm*3500 mm, more large size and less size can be optional.

Know More

- Self-Diagnosis system with touch screen on computer.

- Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input.

- Rotate speed of brush frequency control. (optional)

- Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19 mm.

- High speed cleaning ( max 14 m/min), Low noise ( max 70 dB), high availability working. (25 second /unit)

- Automatic detection of Low-E glass and alarm for coating in reverse. (optional)

- Structure stepped and three-layer I.G. unit available. (optional)

- Precision of plate press: ±0.3 mm

Know More

Etapas de trabalho detalhadas

Características estruturais

Saber mais

- A máquina de lavar vidro pode limpar vidro plano comum ou vidro revestido com uma espessura de 3~12mm;

- A área de limpeza usa 3 pares de escovas ou opcional 4 pares de escovas (ou escovas macias importadas, revestimento ou LOE especial), duas ou quatro limpeza de água;

- A máquina adota uma estrutura vertical inclinada, o vidro plano é colocado no rolo transportador, passa pela seção de alimentação, seção de limpeza e secagem e chega à seção de descarga para concluir a tarefa de limpeza do vidro;

- A área de limpeza e o tanque de água são feitos de aço inoxidável e materiais resistentes à corrosão; a faca de vento inclinada com vento forte pode secar a superfície do vidro;

- A seção de descarga é equipada com lâmpadas de inspeção para verificar a qualidade de limpeza do vidro. A máquina é fácil de operar e os botões de operação estão concentrados na mesa de operação.

Saber mais

Parâmetro técnico

Parâmetros:

Saiba mais

- Dimensões máximas do vidro: 2000 mm * 2500 mm

- Dimensões mínimas do copo: 2500 mm * 3000 mm

- Direção de trabalho voltada para o equipamento

- Velocidade de lavagem: 2-10 m/min

- Espessura do vidro: 3-15 mm

- Espessura do vidro isolante: ≤40 mm

- Abastecimento de água: 0,5 toneladas/dia de água circulante, condutividade ≤40μS

- Velocidade de lavagem: 2-10 m/min

- Altura de trabalho: 580 mm

- Alimentação: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, de acordo com a norma DIN 40040.

- Umidade relativa do ar: ≤ 75%, de acordo com a norma DIN 40040.

Saiba mais

Descrição técnica

Benefits & Advantages

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More

Máquina de lavar e secar vidro horizontal

LIJIANG Glass - Tipo: Máquina de lavar e secar vidro horizontal LJWQ-1800

Princípio Básico de Funcionamento

Máquina de lavar e secar vidro horizontal LJWBQJ1800 usada para lavar e secar as superfícies superior e inferior do vidro float comum e vidro baixo e de alta qualidade, é composta de segmento de entrada, segmento de secagem ao ar de lavagem e segmento de saída. Esta lavadora de tipo econômico sempre é usada para processamento de vidro simples ou vidro isolante arquivado.

Saber mais

Saber mais

Etapas de trabalho detalhadas

Structural Characteristics

1. Aluminum alloy assembled structure, no scrap concept, permanent use,high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift:350 mm,easy to clean and maintain;

6. Three pairs of brush(Ø 150 mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display, the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10. Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11. Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12. Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

Know More

1. Aluminum alloy assembled structure, no scrap concept, permanent use,high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift:350 mm,easy to clean and maintain;

6. Three pairs of brush(Ø 150 mm)Stainless steel shaft configuration (low-e glass, ordinary coated glass and sunshine coated glass can be washed without damaging the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong wind, good air drying effect, with heating system(with temperature control device, optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and good air drying effect,The whole fan box is installed in the upper part of the workshop, with the air filter screen on the side for easy inspection and cleaning;

9. Main drive for gear transmission, frequency control, digital display, the rotation of the brush roller in the washing section is driven by independent belts of the upper and lower motors respectively, the frequency conversion adjustment speed is stable, the service life is long, realizes the cleaning high request special glass;

10. Mechanical button control, cleaning machine digital display, easy to operate, easy to operate, easy to maintain;

11. Washing machine water tank outside, convenient water tank cleaning, water change, check, so that the washing machine cleaning effect is cleaner.

12. Optional with PLC control, touch screen display.It is convenient for workers to operate and maintain, and can be connected to all manufacturers of edge grinding machines without gap.(purchase separately if necessary)

Know More

Parâmetro técnico

| Item. | Spec. |

| Maximum glass width | 2500 mm (effective maximum: 2650 mm) |

| Minimum glass specification | 400 mm*400 mm (limited to single row on left and right sides) |

| Glass thickness | 3 mm-25 mm (digital display) |

| Speed range | glass thickness within 3-25 mm V max=1-12 m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25 mm |

| Total power | 42 KW(water-bearing wind heating: 15 KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length*width*height) | approximately 6260 mm*4800 mm*3100 mm |

| Weight | 3940 kgs |

Know More

Descrição técnica

Benefits & Advantages

The Imported Components

Using imported frequency converter and PLC control system, the speed of entering and exiting the glass can be adjusted freely, and the processing of clear glass can be maintained at a constant speed for a long time.

The 3 Pairs of Rubber Rollers

3 pairs of rubber rollers are used to press the glass sheets, which can achieve the effect of increasing the pressing strength in sequence, and the glass thickness tolerance is smaller than others suppliers.

The High-power Fan

The washing and drying equipment could be equipped with a high-power fan, the drying effect is better, and the cleaning effect of the glass is fully guaranteed.

The Gradient Pressing Method

According to the direction from the glass input to the output, the glass is gradually pressed by using a gradient pressing method. The pressing effect is better than other suppliers.

Know More

The Imported Components

Using imported frequency converter and PLC control system, the speed of entering and exiting the glass can be adjusted freely, and the processing of clear glass can be maintained at a constant speed for a long time.

The 3 Pairs of Rubber Rollers

3 pairs of rubber rollers are used to press the glass sheets, which can achieve the effect of increasing the pressing strength in sequence, and the glass thickness tolerance is smaller than others suppliers.

The High-power Fan

The washing and drying equipment could be equipped with a high-power fan, the drying effect is better, and the cleaning effect of the glass is fully guaranteed.

The Gradient Pressing Method

According to the direction from the glass input to the output, the glass is gradually pressed by using a gradient pressing method. The pressing effect is better than other suppliers.

Know More

Máquina de lavar e secar vidro horizontal

LIJIANG Glass - Tipo: Máquina de lavar e secar vidro horizontal LJWQ-2500A

Princípio Básico de Funcionamento

A Máquina de Lavar Vidros Horizontal Automática LJWQ-2500A consiste nas seções de entrada, lavagem, secagem e saída. Para obter um bom desempenho de lavagem e secagem rápida ao ar, adota 3 pares de escovas e 2 pares de facas de ar com 1 soprador de ar. Serve para vidro temperado, vidro solar, vidro laminado, vidro Low-e ou qualquer outro processamento de vidro plano.

Saber mais

Saber mais

Etapas de trabalho detalhadas

Structural Characteristics

Know More

- Horizontal structure, simple operation. The machine frame adopts heavy thickness aluminum alloy to avoid to be out of shape when working for a longtime.

- With stainless steel water sink and high pressure pre-spraying (high pressure pump) in loading ( in-feed), the rubber roller can pre-wash automatically to clean out the glass powder or scraps.

- Brush: The top and bottom brushes transmit by 1 motor respectively.

- Water tank (with heater):

- 2 water tanks total, 1 for pre-wash, another for washing section.

- Blower: Low noise and vibration.

- Conveying adopts frequent converter, digital display and convenient operation, which do good to connect with double edging line, hollow glass line, safety glass line, etc. Table rollers adapt superior rubber and transmitted by gear wheel which makes a stable working.

- Side covers and tanks and any other water touched material adopt stainless steel 201.

- Washing and Drying section can be lifted to Max. 400 mm by adjustment on electrical board with 4 legs(corners) increasing through motors and encoder.

- 2 pairs air knives adopt advanced technique device, large power and quick air dry.

Know More

Parâmetro técnico

| Item. | Parameter. |

| Max. width | 2500mm |

| Min. size | 400*400mm |

| Glass thickness | 3~28mm |

| Working table height | 900mm±30mm |

| Blower power | 22kw |

| Total power | 32kw |

| Weight | 3000kg |

| Dimension | 5700*3300*2500mm |

| Low-e require | Yes |

| Water heater | Yes |

| Processing speed | 0.5~12m/min |

| Processing-speed suggestion as follow: | |

| 4mm~8mm thickness, speed suggested to 8-12m/min | |

| 10mm~12mm thickness, speed suggested to 4~6m/min | |

| 15mm~19mm thickness, speed suggested to 2-3m/min | |

| 20mm and more, speed suggested to 0.5-1.5m/min | |

| Item. | Spec. |

| Main machine frame | Aluminum alloy + steel, no deformation. |

| High pressure pump | China famous brand: Shanqing |

| Frequency converter of conveying | China famous brand: Kailida |

| Brush motor | China famous brand: Jinxing |

| Bearing | China famous brand: HRE |

| Electrical Appliance | Schneider |

| Rubber roller | NBR Perduran(sour liquid forbiddion), stainless steel 304 shaft |

| Water tank, sink, side covers, all parts touch water | Stainless steel 201 |

| PLC | Siemens |

Know More

Descrição técnica

Benefits & Advantages

The Aluminum Alloy Structure

The whole cleaning equipment adopts aluminum alloy assembled tripod, which is stable and durable, not easy to change. The surface of the aluminum alloy aluminum profile adopts negative oxidation treatment, which is not easy to be corroded by water.

The Water Tank Adopts #201 Stainless Steel

The water tank, the shield and the place in contact with the water are made of #201 stainless steel, which is harder than #304 stainless steel and contains high manganese. Chromium-rich oxides will be formed on the surface of the steel body to protect the steel body from water rust

The Gear Transmission

The equipment adopts gear transmission as a whole, and the transmission efficiency is high, generally η=0.94~0.99; the transmission ratio has a wide range, especially when planetary transmission is used, the transmission ratio can reach 100-200 (single-stage), which is suitable for deceleration or Speed-increasing transmission; reliable operation and long service life.

The Lifting System

The lifting system is driven by a servo motor, driven by a lifting screw, and combined with a gear drive. It has the characteristics of low friction loss, high transmission efficiency, and high axial rigidity. In addition, the starting torque of ball screw pair is Smaller, there will be no crawling phenomenon like sliding motion, and it can ensure the realization of precise micro-feed and high-speed feed.

The Rubber Roller Transmission

The feeding port and the discharging port of the equipment adopt frequency conversion transmission, and the operation screen is displayed for easy operation. The rubber roller is made of high-quality nitrile rubber, driven by gears, and runs smoothly. It can be connected with edging line, hollow line and laminated line for data connection and unified control.

The Imported PLC Control System

The PLC control system can be equipped with the Taiwan Delta or Germany Siemens control system according to the actual requirements of the customer. The PLC control system can be directly connected to the network, connecting the loading and unloading CNC robots to achieve a smart factory with integrated operation.

Know More

The Aluminum Alloy Structure

The whole cleaning equipment adopts aluminum alloy assembled tripod, which is stable and durable, not easy to change. The surface of the aluminum alloy aluminum profile adopts negative oxidation treatment, which is not easy to be corroded by water.

The Water Tank Adopts #201 Stainless Steel

The water tank, the shield and the place in contact with the water are made of #201 stainless steel, which is harder than #304 stainless steel and contains high manganese. Chromium-rich oxides will be formed on the surface of the steel body to protect the steel body from water rust

The Gear Transmission

The equipment adopts gear transmission as a whole, and the transmission efficiency is high, generally η=0.94~0.99; the transmission ratio has a wide range, especially when planetary transmission is used, the transmission ratio can reach 100-200 (single-stage), which is suitable for deceleration or Speed-increasing transmission; reliable operation and long service life.

The Lifting System

The lifting system is driven by a servo motor, driven by a lifting screw, and combined with a gear drive. It has the characteristics of low friction loss, high transmission efficiency, and high axial rigidity. In addition, the starting torque of ball screw pair is Smaller, there will be no crawling phenomenon like sliding motion, and it can ensure the realization of precise micro-feed and high-speed feed.

The Rubber Roller Transmission

The feeding port and the discharging port of the equipment adopt frequency conversion transmission, and the operation screen is displayed for easy operation. The rubber roller is made of high-quality nitrile rubber, driven by gears, and runs smoothly. It can be connected with edging line, hollow line and laminated line for data connection and unified control.

The Imported PLC Control System

The PLC control system can be equipped with the Taiwan Delta or Germany Siemens control system according to the actual requirements of the customer. The PLC control system can be directly connected to the network, connecting the loading and unloading CNC robots to achieve a smart factory with integrated operation.

Know More