Verre sous vide : une technologie révolutionnaire pour résoudre les problèmes d'économie d'énergie et de condensation des congélateurs de supermarchés

Au quotidien, les réfrigérateurs sont l'équipement essentiel pour garantir la qualité des produits frais. Pourtant, ils représentent une facture d'électricité conséquente, représentant jusqu'à 70 % de la consommation totale du supermarché. Plus problématique encore pour les exploitants, la condensation et la buée sur les portes vitrées des réfrigérateurs sont fréquentes, ce qui non seulement empêche les clients de bien voir les produits et nuit à leur désir d'achat, mais oblige également les vendeurs à les essuyer à plusieurs reprises, ce qui impacte non seulement les ventes, mais augmente également les coûts de gestion. Les solutions traditionnelles de vitrage isolant, et même de vitrage chauffant électrique, n'ont jamais permis de résoudre simultanément les deux principaux problèmes que sont la consommation d'énergie et la condensation. Cependant, l'application mature de la technologie du verre sous vide devrait permettre de résoudre ces deux problèmes majeurs. 1. Les inconvénients cachés des coûts des réfrigérateurs de supermarché

Les réfrigérateurs de supermarchés sont confrontés à deux obstacles techniques majeurs dans leur fonctionnement à long terme, qui se traduisent par de nombreux problèmes de coûts : condensation et buée sur les portes vitrées.

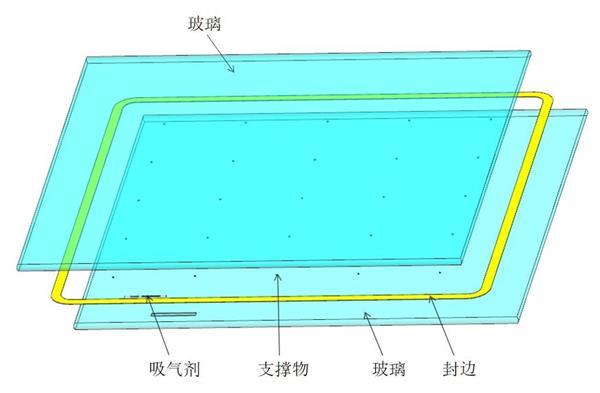

Lorsque l'intérieur du réfrigérateur est à basse température (même jusqu'à -25 °C ou moins) et que l'extérieur est soumis à une température et une humidité élevées (par exemple, une humidité supérieure à 80 % en été), la température de surface du verre ordinaire chute brutalement en dessous du point de rosée et le brouillard d'eau se condense rapidement, brouillant la visibilité des produits. Cela affecte non seulement le choix des clients, mais oblige également le personnel du magasin à essuyer le verre à plusieurs reprises, ce qui augmente les coûts de main-d'œuvre. La consommation énergétique reste élevée. Les portes des réfrigérateurs sont des éléments clés de l'échange thermique. Le coefficient de transfert thermique (valeur U) du verre isolant traditionnel est généralement supérieur à 1,8 W/m²K, ce qui entraîne des fuites d'air froid continues. Le compresseur doit fonctionner à haute fréquence, ce qui consomme beaucoup d'électricité et augmente considérablement la facture d'électricité des supermarchés. Afin de résoudre ce problème de condensation, l'industrie a introduit le verre chauffant électrique, qui augmente la température de surface en chauffant le verre grâce à l'intégration de fils métalliques dans l'intercalaire. Cependant, cette solution pose de nouveaux problèmes : elle consomme davantage d'électricité (une seule porte consomme 1 à 2 kWh par jour), augmente les pertes d'air froid (la température du verre augmente après chauffage et le transfert de chaleur vers l'armoire est renforcé), et même les contraintes causées par les variations de température augmentent le risque d'auto-explosion. Le chauffage électrique du verre semble résoudre le problème de la buée, mais il est en réalité tombé dans un cercle vicieux : « Consommation d'électricité pour résister à la condensation, et la consommation d'énergie augmente lorsque la condensation n'est pas éliminée. » 2. Le principe de « super isolation » du verre sous vide. La principale innovation du verre sous vide réside dans sa structure innovante : une couche de vide (pression d'air inférieure à 0,01 Pa) est construite entre deux plaques de verre trempé. L'intérieur est séparé par des supports de l'ordre du micron, et les bords sont scellés par des joints haute température et des getters pour maintenir le vide. Le vide ne transférant pas la chaleur, le transfert thermique repose uniquement sur un faible rayonnement et des ponts thermiques ponctuels, ce qui lui permet d'atteindre des performances d'isolation thermique 3 à 5 fois supérieures à celles du verre isolant. Prenons l'exemple du verre Landy V de Luoyang Landy : son coefficient de transfert thermique (valeur