Al producir el vidrio aislante, ¿qué tipo de sellador se debe usar para el segundo sello?

When producing the insulated glass, what kind of sealant should be used for the second seal?

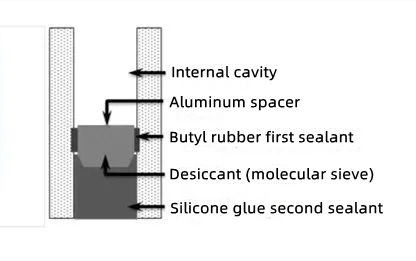

1. Insulating glass is a product that evenly separates two or more pieces of glass at a certain distance,

and the periphery is bonded and sealed, so that a dry gas space is formed between the glass layers. The gas layer can be air or other inert gas. According to the thickness of the gas layer required by the design, insert a spacer frame containing a desiccant between the two pieces of glass, and then perform two seals on the periphery of the glass: the first seal (inner layer seal) is to seal the gap between the spacer frame and each piece of glass The inner layer gap, the standard requires that butyl hot-melt sealant should be used; the second seal (outer layer seal) is to seal the outer layer gap between the perimeter of the two pieces of glass and the spacer frame, and the standard requires that silicone structural sealant be used Or polysulfide sealant.

2. The properties of the three sealants used in the production of insulating glass are different:

① The sealing performance of the butyl hot-melt sealant used in the first seal is better than that of silicone glue and polysulfide glue, but the bonding strength is lower. It is used for inner layer sealing and can make up for the shortage of silicone glue and polysulfide glue is very suitable. No matter what kind of glass curtain wall is used, the inner layer should be sealed with butyl hot-melt sealant.

② The silicone structural sealant used in the second seal has high bonding strength, good UV resistance, and good compatibility with the sealant of the curtain wall panel caulking; while the polysulfide sealant has low bonding strength Higher, but poor UV resistance, easy aging, and incompatible with silicone sealants. Therefore, the norms have strict differences and restrictions on the use of these two sealants.

3. The hollow glass joints of hidden frames, semi-hidden frames, and point-supported glass curtain walls (including hidden frame windows) are exposed outside, exposed to ultraviolet radiation for a long time, and when the glass is subjected to loads such as wind pressure and self-weight, Without frame support, once the sealant fails to bond, the outer glass will be in danger of falling. Therefore, the second seal of the insulating glass must use silicone structural sealant to ensure safety. Due to the poor UV resistance of polysulfide sealant and incompatibility with silicone sealant, it is not allowed to be used for the second sealing of insulating glass of the hidden frame, semi-hidden frame, and point-supported glass curtain wall.

Insulating glass is used for exposed frame glass curtain walls and framed doors and windows. Because the glass is embedded in the curtain wall or door and window frame, it is not exposed to direct ultraviolet rays, and generally does not come into contact with silicone sealant, so polysulfide should be used for the second sealant. Sealant (silicon-type sealant can also be used).

4. Because the insulating glass used for the hidden frame glass curtain wall is subject to various loads, the size of the glue joint must be determined after structural calculation.

5. Relationship between sealing quality and curtain wall safety and energy saving:

When the insulating glass is used as the panel of the hidden frame glass curtain wall (including the hidden frame window), if the two pieces of glass of the insulating glass are not well bonded, the bonding between the outer glass and the inner glass will fail, resulting in serious accidents such as falling off the glass from high altitude.