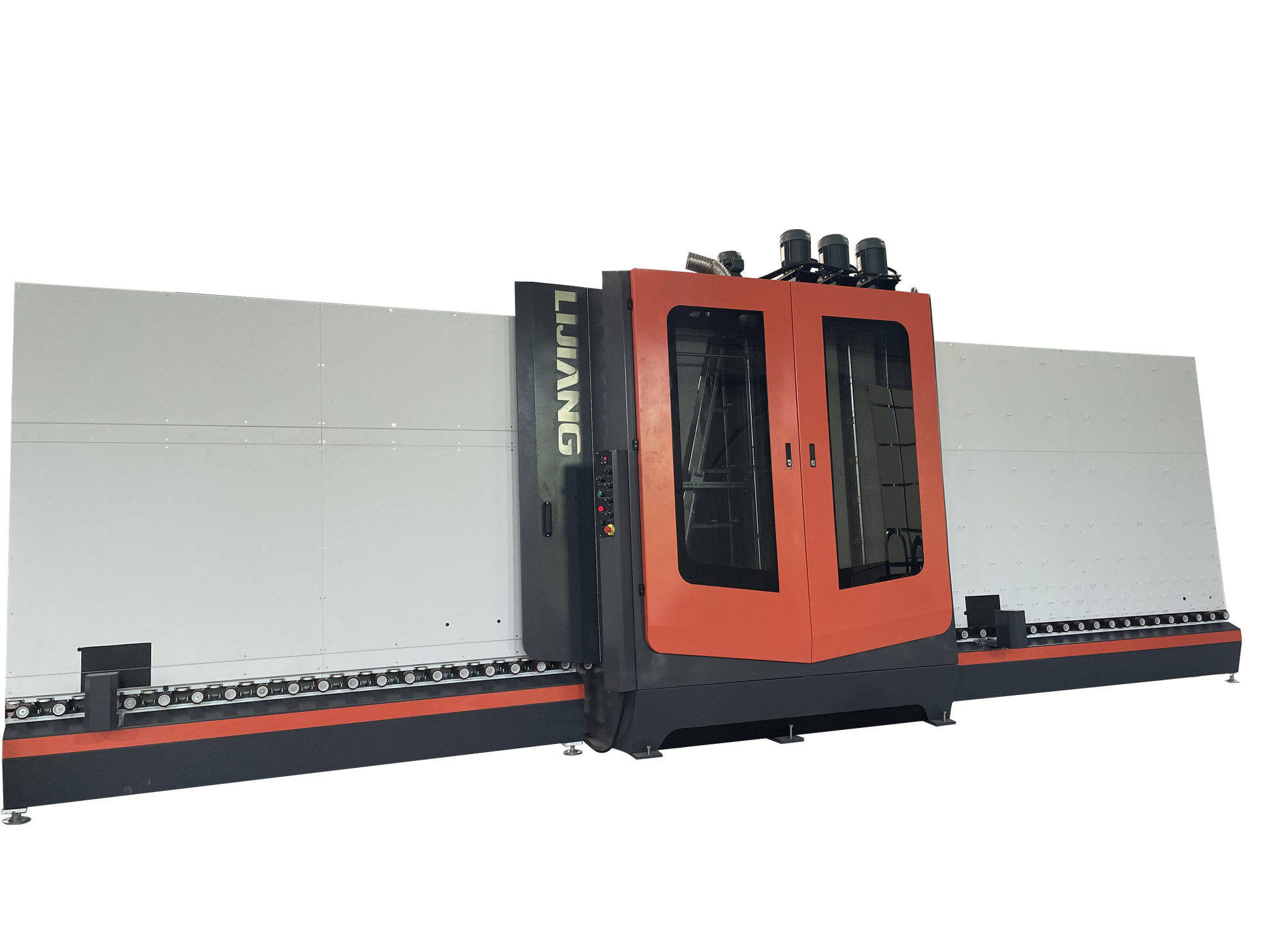

Lavadora y secadora de vidrio vertical

Vidrio LIJIANG

Más detalles de equipos automáticos

Principio de funcionamiento básico

LJLQ-2500 glass washing and drying machine could wash max glass of 2500 mm*3500 mm, more large size and less size can be optional.

Know More

- Self-Diagnosis system with touch screen on computer.

- Stainless steel washer with 8 ( 6 ) brushes, soft brushes from MONFORTS of Germany, hard brushes automatically open when Low-E glass input.

- Rotate speed of brush frequency control. (optional)

- Stainless steel air knife is automatically adjustable according to glass thickness, Max thickness to 19 mm.

- High speed cleaning ( max 14 m/min), Low noise ( max 70 dB), high availability working. (25 second /unit)

- Automatic detection of Low-E glass and alarm for coating in reverse. (optional)

- Structure stepped and three-layer I.G. unit available. (optional)

- Precision of plate press: ±0.3 mm

Know More

Pasos de trabajo detallados

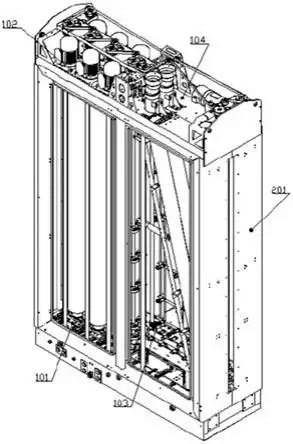

Características estructurales

Saber más

- La lavadora de vidrio puede limpiar vidrio plano común o vidrio revestido con un espesor de 3 a 12 mm;

- El área de limpieza utiliza 3 pares de cepillos u opcionalmente 4 pares de cepillos (o cepillos suaves importados, de recubrimiento o especiales LOE), limpieza con dos o cuatro aguas;

- La máquina adopta una estructura vertical inclinada, el vidrio plano se coloca en el rodillo transportador, pasa por la sección de alimentación, la sección de limpieza y secado y llega a la sección de descarga para completar la tarea de limpieza del vidrio;

- El área de limpieza y el tanque de agua están hechos de acero inoxidable y materiales resistentes a la corrosión; el cuchillo de viento inclinado con viento fuerte puede secar la superficie del vidrio;

- La sección de descarga está equipada con lámparas de inspección para verificar la calidad de limpieza del vidrio. La máquina es fácil de operar y los botones de operación se concentran en la mesa de operaciones.

Saber más

Parámetro técnico

Parámetros:

Saber más

- Tamaño máximo del vidrio: 2000 mm x 2500 mm

- Tamaño mínimo del vidrio: 2500 mm x 3000 mm

- Dirección de trabajo frente al equipo

- Velocidad de lavado: 2-10 m/min

- Espesor del vidrio: 3-15 mm

- Espesor del vidrio aislante: ≤40 mm

- Suministro de agua: 0,5 toneladas/día de agua circulante, conductividad ≤40μS

- Velocidad de lavado: 2-10 m/min

- Altura de trabajo: 580 mm

- Potencia: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, según DIN 40040

- Humedad relativa del aire: ≤ 75 %, según DIN 40040

Saber más

Descripción técnica

Benefits & Advantages

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180 mm + four sprays, the glass is cleaned and the speed is fast (10-12 m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the cleaning box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Know More