Mesa de carga de corte automático de vidrio

Vidrio LIJIANG

Principio de funcionamiento básico

Se utiliza principalmente para la carga automática de vidrio. Después de colocar el vaso en la posición designada y dar la señal de carga, el brazo grande gira unos 95 grados a través del mecanismo de vuelco y toda la máquina comienza a moverse hacia adelante. Cuando el dispositivo de inducción en el brazo pequeño toca el vidrio, toda la máquina deja de caminar y la ventosa succiona el vidrio a través del sistema de vacío en el vidrio, el motor de elevación del brazo pequeño levanta el vidrio hacia arriba y hacia atrás unos 80 mm. El motor ambulante retrocede y el gran brazo cae. Cuando el brazo de tracción está en su lugar, la ventosa debajo del vidrio comienza a soplar. Cuando el brazo pequeño cae, el vidrio cae sobre la rueda transportadora. Finalmente, el vidrio es transportado a la mesa de corte por la rueda transportadora.

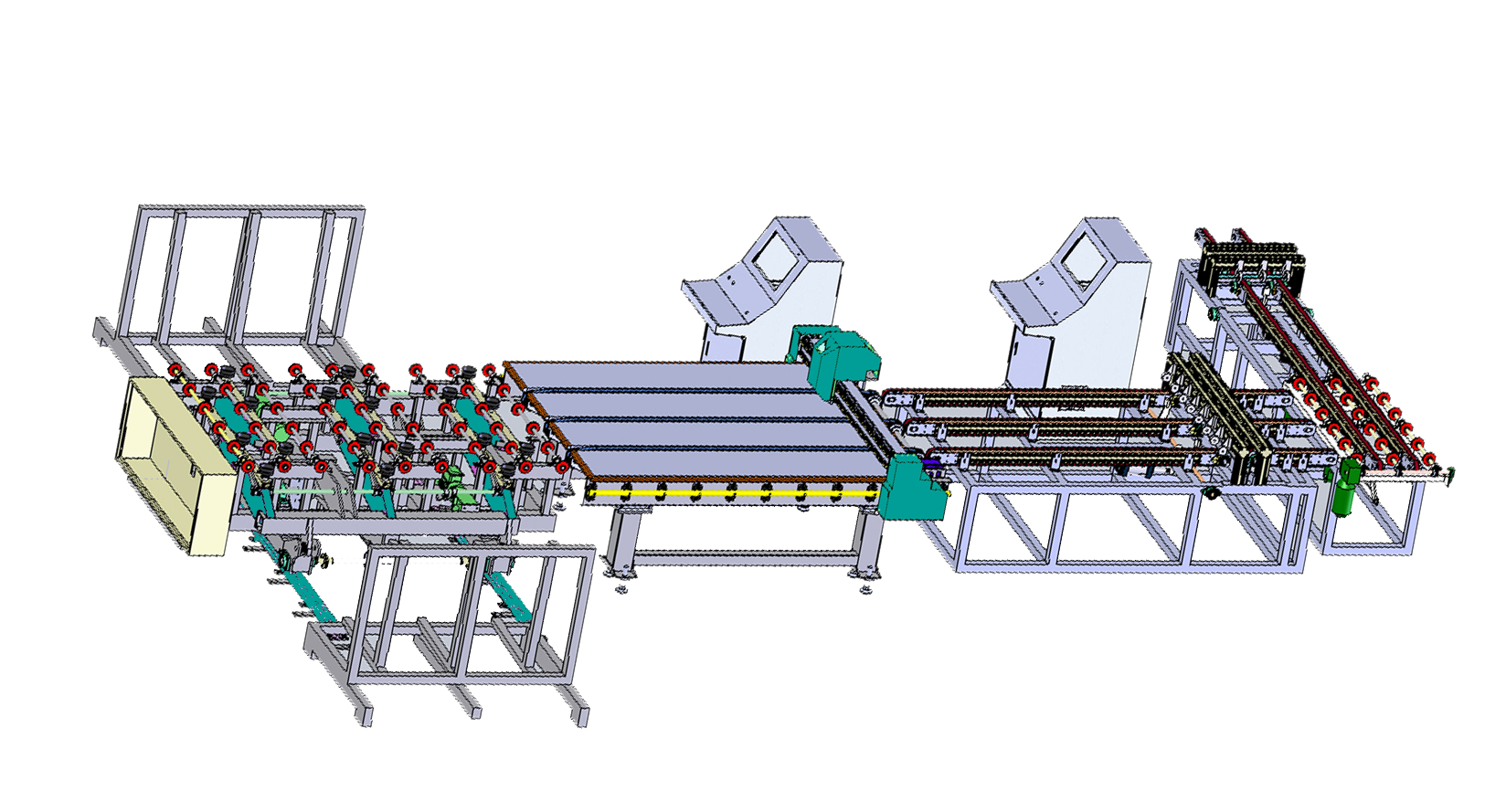

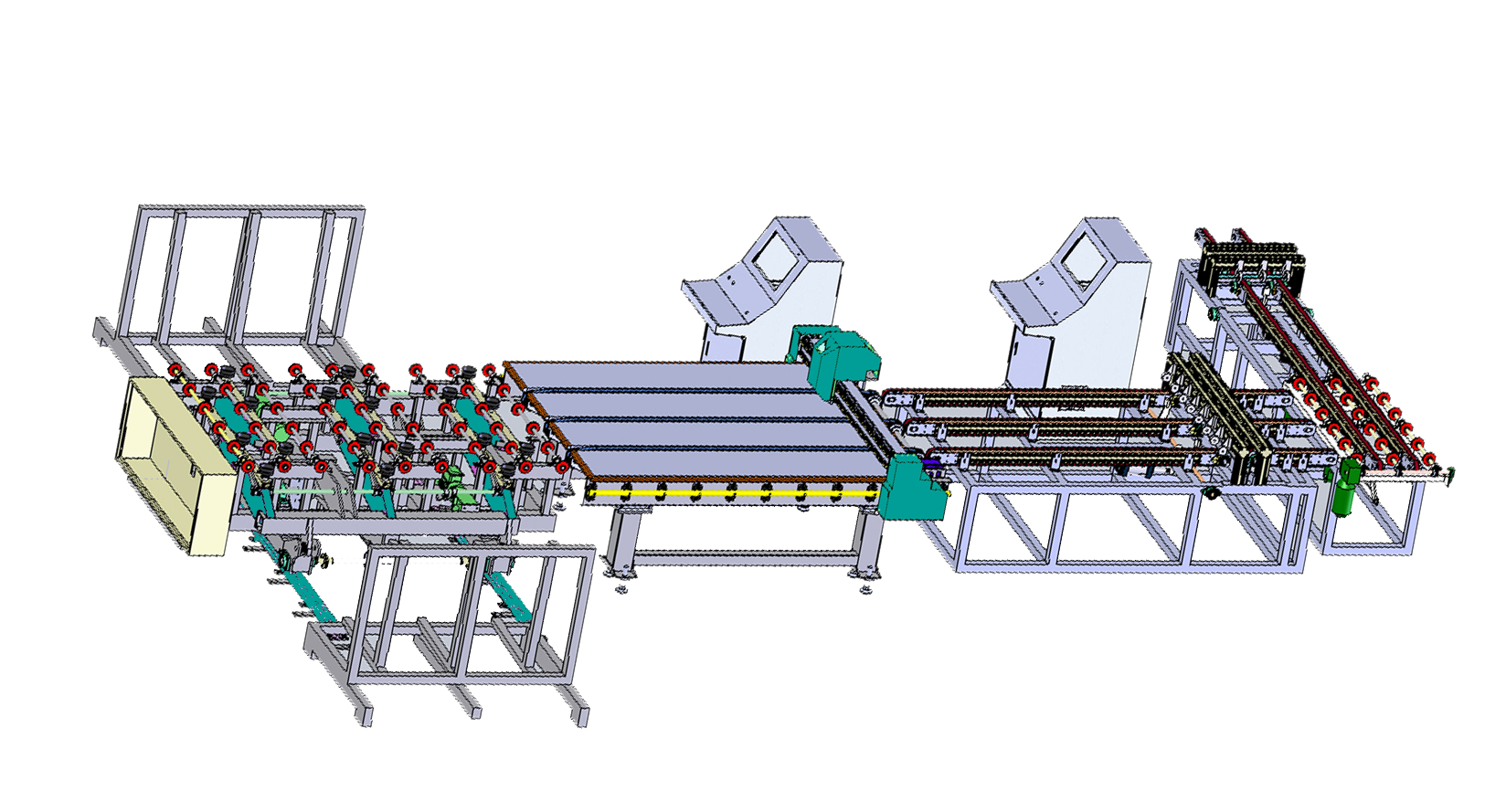

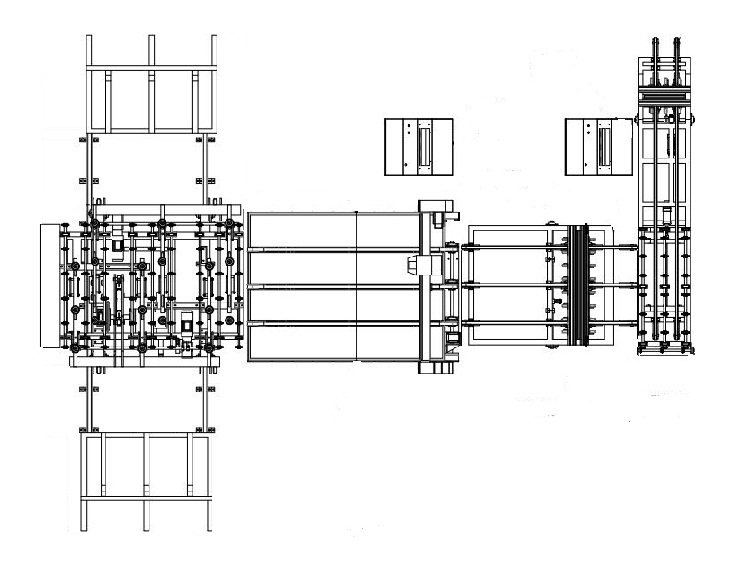

Línea de alimentación, corte y rotura de vidrio completamente automática

Línea de alimentación, corte y rotura de vidrio completamente automática

Línea de alimentación, corte y rotura de vidrio completamente automática

Línea de alimentación, corte y rotura de vidrio completamente automáticaPasos de trabajo detallados

Todo el proceso de trabajo puede realizarse mediante control automático PLC o control manual. El modo manual es principalmente adecuado para el ajuste y el mantenimiento de equipos.

Cada acción se puede completar de forma independiente o se puede utilizar para el trabajo normal. Después de dar la señal de carga (manual y automática), el brazo gira hacia arriba unos 95 grados a través del mecanismo de vuelco y toda la máquina comienza a moverse hacia adelante.

Cuando el dispositivo de inducción del brazo toca el vidrio, la máquina se detiene. El sistema de vacío funciona: el vidrio es succionado por la ventosa. Cuando la presión de vacío alcanza la presión establecida, la bomba de vacío se detiene. El mecanismo de biela telescópica de la ventosa eleva el vidrio 80 mm hacia atrás y hacia arriba mediante el motor del brazo.

Tras detenerse durante aproximadamente 1,5 segundos para asegurar la succión del vidrio, el brazo grande, accionado por un motor, lo dirige hacia el rodillo de transmisión. La ventosa bajo el vidrio comienza a soplar, y el mecanismo de biela telescópica hace que la ventosa y el vidrio caigan simultáneamente.

Cuando el vidrio cae sobre el rodillo transportador, el brazo pequeño continúa cayendo, el vidrio se separa de la ventosa y el transportador comienza a enviar la lámina de vidrio al extremo frontal de la máquina de carga y se detiene en el punto de señal. Luego, todo el marco se mueve automáticamente para encontrar la posición cero y se detiene.

Esperando la señal de la mesa de corte, el vidrio se envía a la mesa a la misma velocidad que la cinta transportadora de la máquina. Tras el envío, el ciclo de trabajo se repite automáticamente. La máquina puede seleccionar cualquier posición según el espesor requerido.

Cada acción se puede completar de forma independiente o se puede utilizar para el trabajo normal. Después de dar la señal de carga (manual y automática), el brazo gira hacia arriba unos 95 grados a través del mecanismo de vuelco y toda la máquina comienza a moverse hacia adelante.

Cuando el dispositivo de inducción del brazo toca el vidrio, la máquina se detiene. El sistema de vacío funciona: el vidrio es succionado por la ventosa. Cuando la presión de vacío alcanza la presión establecida, la bomba de vacío se detiene. El mecanismo de biela telescópica de la ventosa eleva el vidrio 80 mm hacia atrás y hacia arriba mediante el motor del brazo.

Tras detenerse durante aproximadamente 1,5 segundos para asegurar la succión del vidrio, el brazo grande, accionado por un motor, lo dirige hacia el rodillo de transmisión. La ventosa bajo el vidrio comienza a soplar, y el mecanismo de biela telescópica hace que la ventosa y el vidrio caigan simultáneamente.

Cuando el vidrio cae sobre el rodillo transportador, el brazo pequeño continúa cayendo, el vidrio se separa de la ventosa y el transportador comienza a enviar la lámina de vidrio al extremo frontal de la máquina de carga y se detiene en el punto de señal. Luego, todo el marco se mueve automáticamente para encontrar la posición cero y se detiene.

Esperando la señal de la mesa de corte, el vidrio se envía a la mesa a la misma velocidad que la cinta transportadora de la máquina. Tras el envío, el ciclo de trabajo se repite automáticamente. La máquina puede seleccionar cualquier posición según el espesor requerido.

Parámetro técnico

- Tamaño de hoja: Tamaño mínimo: 2400*1500 mm (Carga por un solo lado)

- Tamaño máximo de carga: 6100* 3300 mm

- Grosor de la hoja de vidrio: 3 ~ 19 mm

- Profundidad de absorción de trabajo: 700 mm

- Velocidad de marcha del eje X: 5-25 m/min (ajustable)

- Velocidad de marcha del eje Y: 8-12 m/min (ajustable)

- Velocidad de transporte: 5-25 m/min (ajustable)

- Número de brazos abatibles: 12 brazos (carga lateral doble)

- Número de ventosas de un solo brazo: Tres

- Tipo de carga: Carga lateral doble

- Ciclo de trabajo: 60 S (30 S por cada posición adicional)

- Fuente de alimentación de la instalación: CA 380 V/50 Hz (las circunstancias especiales se pueden ajustar según los requisitos del cliente)

- Potencia total instalación: 8-17 kw

- Aire comprimido: 0,6-0,8 Mpa;

- Vacío: -50-99 Kpa (regulable según espesor del vidrio)

- Altura de la mesa de trabajo: 900 + 20 mm

- Tamaño de la máquina: 4650*2980*900mm

Descripción técnica

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line