Maquinaria de vidrio LIJIANG se presentará en Glasspro India 2025: Liderando el futuro del procesamiento inteligente de vidrio

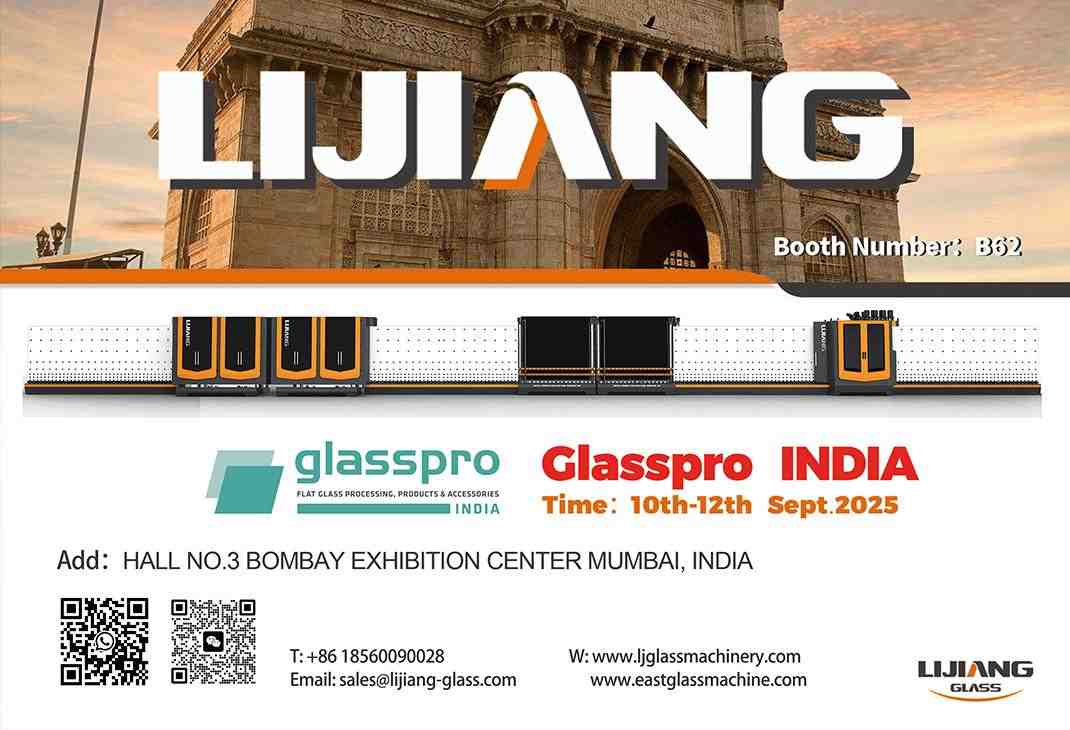

Glasspro India 2025 – International Exhibition for Flat Glass Processing Products and Accessories will be held from September 10–12, 2025 at the Bombay Exhibition Center, Goregaon East, Mumbai, India. As one of the most influential glass industry events in South Asia, the exhibition will gather glass machinery manufacturers, raw material suppliers, and professional buyers from across the globe.LIJIANG Glass Machinery will participate as a key exhibitor, presenting its latest innovations and intelligent solutions for flat glass processing.

LIJIANG’s Exhibition Highlights

- Automatic Glass Cutting Machine – CNC-controlled for high-precision straight and shaped cutting.

- Insulating Glass Production Line – Highly automated, meeting energy-efficient building glass needs.

- Glass Washing Machine – Efficient cleaning and drying, ensuring premium glass quality.

- Glass Grinding & Polishing Machine – Suitable for straight edge, round edge, bevel, and more.

- Automatic Glass Sealing Robot – Enhances IGU sealing speed and consistency.

With its strengths in smart manufacturing, energy efficiency, and stable performance, LIJIANG equipment has been widely applied in architectural glass, automotive glass, and home appliance glass industries worldwide.

Why Choose LIJIANG Glass Machinery?

- Global Experience – Exported to Europe, Middle East, Southeast Asia, India, and beyond.

- Complete Solutions – Covering cutting, washing, edging, and insulating glass production equipment.

- Smart Technology – Continuous innovation in automation and digitalized glass production.

- Localized Service – Expanding service networks in India with responsive technical support.

Exhibition Dates: September 10–12, 2025

Venue: Bombay Exhibition Center, Goregaon East, Mumbai, IndiaLIJIANG Glass Machinery warmly welcomes global clients and partners to join us at Glasspro India 2025 and explore the future of glass processing together!