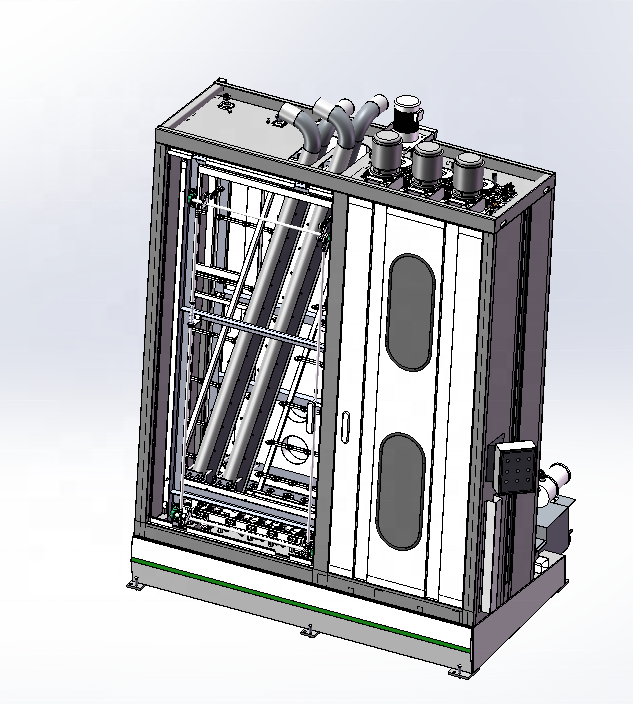

Lavadora y secadora de vidrio vertical

Vidrio LIJIANG

Más detalles de equipos automáticos

Principio de funcionamiento básico

The overall structure of the LJLQ-2000 vertical glass washing and drying machine is composed of four sections: inlet section, air-drying section, and outlet section. It is mainly composed of four major mechanisms: conveying, cleaning, strong wind, and inspection. It has the characteristics of strong decontamination ability, cleanliness, and good air-drying effect.

Know More

Know More

Pasos de trabajo detallados

Características estructurales

Saber más

- El cepillo cilíndrico en la parte de limpieza es transportado por una correa independiente del motor. El cepillo está hecho de material resistente a los ácidos y a altas temperaturas de alta calidad, que tiene un buen efecto de limpieza y una larga vida útil.

- Adopta un sistema de transmisión preciso y una regulación de velocidad de conversión de frecuencia, que se puede operar directamente en el panel para ajustar la velocidad de limpieza arbitrariamente.

- Los rodillos de goma transportadores de alta calidad están densamente dispuestos y pueden procesar diferentes tamaños de vidrio. Combinado con la transmisión de engranajes, la transmisión de vidrio es más estable.

- Usando un sistema eficiente de limpieza y secado al aire, el vidrio de diferentes espesores se puede limpiar y secar automáticamente; se limpia con un cepillo, se seca con un rodillo de esponja de alta calidad y luego se seca con aire caliente una vez para garantizar que el efecto de limpieza del vidrio sea limpio y brillante sin dejar rastros de manchas de limpieza.

Saber más

Parámetro técnico

Parámetros:

Saber más

- Tamaño máximo del vidrio: 2000 mm x 2500 mm

- Tamaño mínimo del vidrio: 2500 mm x 3000 mm

- Dirección de trabajo frente al equipo

- Velocidad de lavado: 2-10 m/min

- Espesor del vidrio: 3-15 mm

- Espesor del vidrio aislante: ≤40 mm

- Suministro de agua: 0,5 toneladas/día de agua circulante, conductividad ≤40μS

- Velocidad de lavado: 2-10 m/min

- Altura de trabajo: 580 mm

- Alimentación: 3P 380V 50Hz

- Temperatura ambiente: 10°C-30°C, según DIN 40040

- Humedad relativa del aire: ≤ 75 %, según DIN 40040

Saber más

Descripción técnica