Dobladora automática de espaciadores de aluminio y vidrio aislado

Vidrio LIJIANG

Más detalles de equipos automáticos

Principio de funcionamiento básico

General Performance

Optional Performance

- Adopts the servo control feeding system, the size of aluminum spacers could be adjusted with an accuracy of 0.1 mm/m;

- CNC Bending angle control system with adjustable accuracy of 0.1°;

- Sets up four groups of aluminum spacers and stainless steel spacers storage units;

- Aluminum spacer bars with multiple sizes could be selected at will;

- Automatically adjust the bending speed according to the size of the aluminum spacer or stainless steel spacer to avoid the deformation of the large spacer and ensure the high speed and continuity of the small frame;

- Automatic continuous connection of spacer, cutting spacer, avoidance of spacer joint;

- No material prompt, sleep prompt, fault prompt, work prompt, unreasonable data refuse processing and prompt support arc-shaped aluminum spacer and special shaped aluminum spacer bending;

- USB function, which could read EXCEL directly;

Optional Performance

- Could connect with ERP system;

- Could optional the function of automatic printing code, automatic printing label, bending the stainless steel spacer, bending the warm edge spacer, bending the stainless steel composite warm edge strips, bending the glass fiber warm edge strips, and bending the pure opaque steel strips.

Pasos de trabajo detallados

Pasos operativos

- Encienda la alimentación, encienda el interruptor de funcionamiento en la consola de control y presione la bomba de aceite para arrancar.

- Ajusta el trazo. Preste atención a ajustar la carrera antes de su uso; y se debe establecer un espacio cuando la máquina dobladora sube y baja hasta el fondo. El ajuste sin espacio provocará cierto desgaste en el equipo de la máquina dobladora.

- Selección de la muesca de la dobladora. La base de selección es: el espesor de la placa de vidrio es aproximadamente 8 veces el ancho. Por ejemplo, si el espesor de la placa de vidrio es de 5 cm, entonces la muesca debe ser de 40 cm.

- Ajuste manual o eléctricamente el tope detrás de la máquina dobladora.

- Presione el interruptor del pedal para realizar la flexión.

- Durante el procesamiento, se debe observar en todo momento el estado y el efecto del procesamiento del vidrio para evitar fallas en el equipo o productos defectuosos.

- Cuando la máquina dobladora deje de funcionar, apague el interruptor de funcionamiento de la mesa de operaciones, luego apague la alimentación y limpie la superficie de trabajo de la máquina dobladora para que quede limpia y ordenada para el próximo uso.

Parámetro técnico

| Item. | Spec. |

| Max. Bending Size | 1800*2000 mm (in once)/ 2500*4000 mm(in twice) |

| Min. Bending Size | 150*300 mm |

| Aluminum Spacer Width | 5.5-26.5 mm |

| Spacers Racks | 4 |

| Spacer Size Error | ±0.5 mm |

| Angle Error | ±1° |

| Conveying Speed | 1250 mm/s |

| Air Pressure | ≥0.65 MPa |

| Voltage | 380 50Hz 3P |

| Total Power | 2.5 Kw |

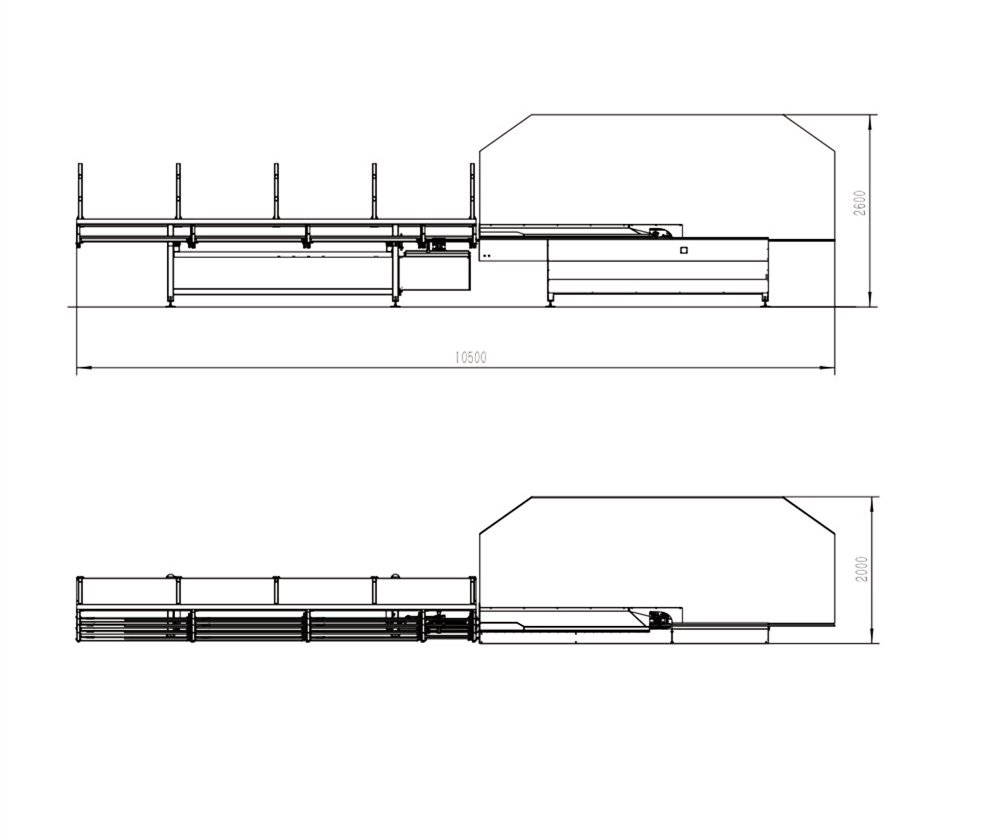

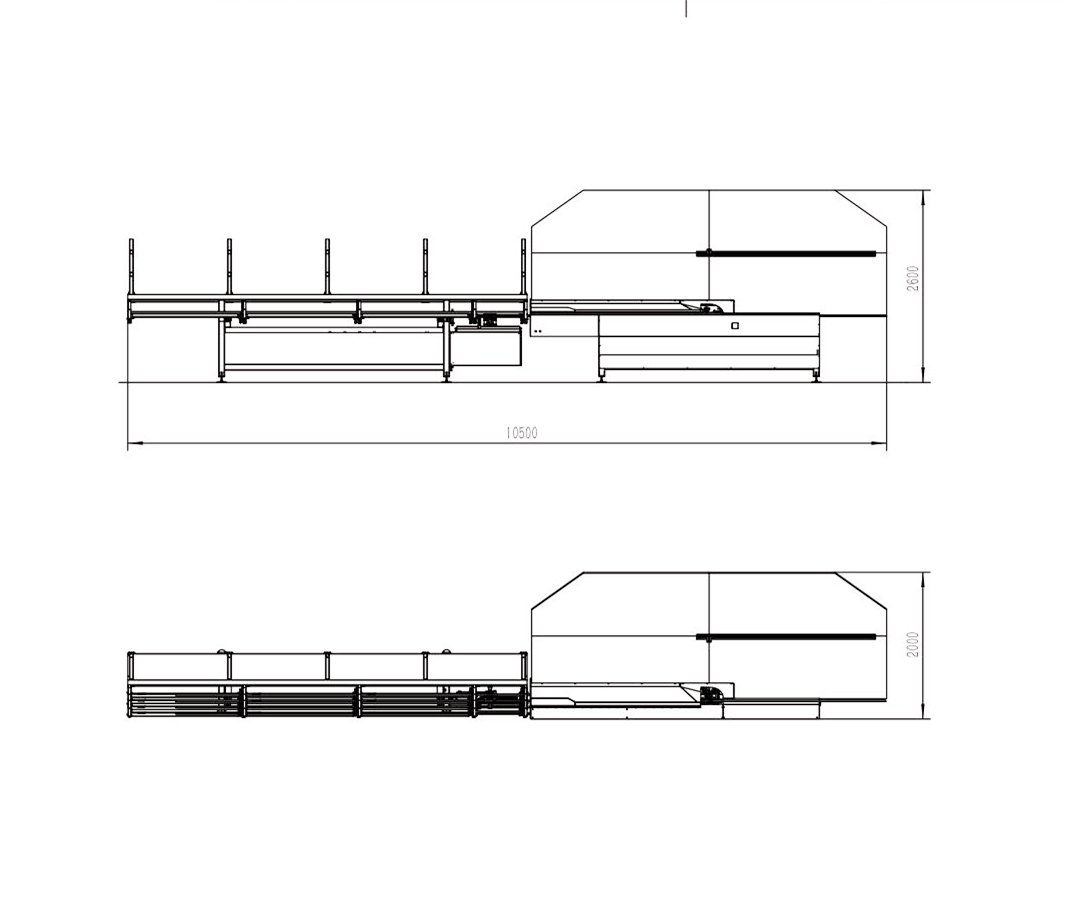

| Dimension(L*W*H) | 10500 mm*2200 mm*2600 mm |

| Weight | 1580 kg |

Descripción técnica

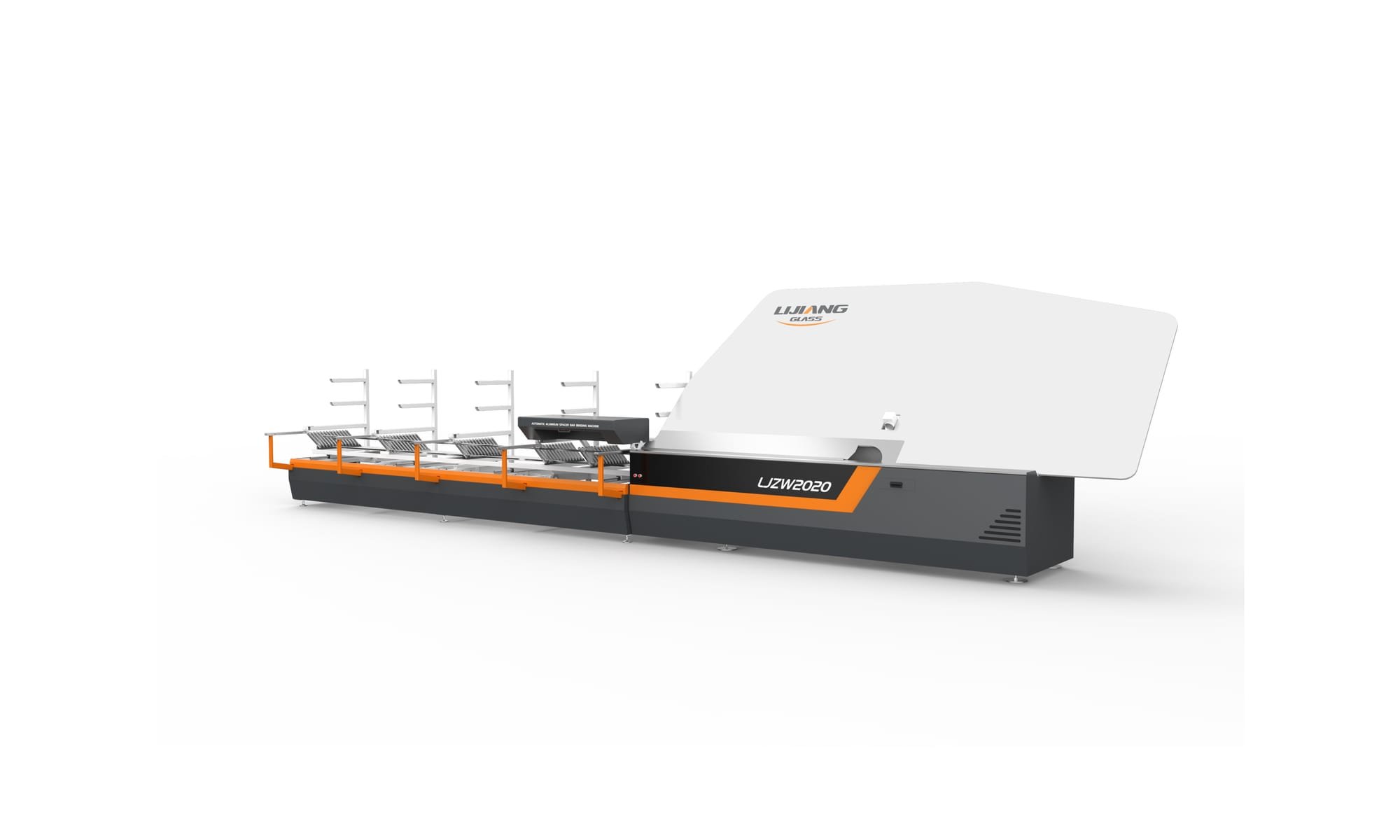

Máquina dobladora de espaciadores de aluminio para vidrio aislante LJZW2020

Máquina dobladora de espaciadores de aluminio para vidrio aislante LJZW2020 Máquina dobladora de espaciadores de aluminio para vidrio aislante LJZW2020A

Máquina dobladora de espaciadores de aluminio para vidrio aislante LJZW2020A