Equipo automático de robot de sellado de vidrio aislado

Vidrio LIJIANG

Más detalles de equipos automáticos

Principio de funcionamiento básico

- Adopta el sistema de control servo Yaskawa de Japón, completamente automático y de alta eficiencia;

- Función de memoria automática, sin necesidad de ingresar parámetros repetidamente;

- Reparación automática de esquinas de vidrio con raspador y rodillo;

- La sección de transporte del equipo se puede dividir en cuatro secciones y el vidrio se puede almacenar previamente;

- Mida automáticamente el tamaño del vidrio y la profundidad del vidrio, ajuste la velocidad de sellado;

- Adopte la correa de distribución, la transferencia suave y la posición precisa;

- Cada función automática es con operación manual;

- Podría recubrir el doble acristalamiento, vidrio moldeado, vidrio escalonado, triple vidrio.

- Un juego de bomba de refuerzo controla dos grupos de selladores;

- Función de descarga de sellador de sincronización automática;

- El sistema de mezcla de sellador adopta una estructura antibloqueo y es fácil de limpiar.

Pasos de trabajo detallados

Equipment preparation: a. Make sure the power connection of the sealing line is normal, and confirm that the required air source and glue supply system are working properly. b. Check whether all components and sensors of the sealing line are intact, and perform necessary maintenance and cleaning.

Set parameters: a. On the control interface of the sealing line, set relevant parameters, such as glass plate size, sealing speed, sealing width, sealing thickness, etc. Set parameters according to product requirements and process specifications. b. If using two-component glue, you need to set the glue ratio and mixing time.

Start the sealing robot equipment: a. Press the start button to start the sealing robot equipment. Ensure the safety of the insulating glass production line and wait for the sealing robot equipment to enter normal working conditions.

Automatic conveying of glass plates: a. Place the glass plate to be sealed on the conveyor belt or transmission mechanism to ensure that the position and positioning of the glass plate are accurate.

Automatic sealant sealing application: a. The sealing line will automatically apply sealant evenly to the edge of the glass plate or the parts that need to be sealed according to the set parameters. Ensure that the sealing robot equipment works stably and the glue is sprayed evenly.

Glass plate fixing: a. After the sealant is sprayed, the sealing line will fix another glass plate to be sealed on the glass plate that has been coated with sealant. Make sure the glass panels are aligned accurately and sealed tightly.

Sealant sealing and compression: a. The insulating glass sealing robot machine will perform a certain pressure treatment on the two glass plates to ensure a tight combination of the sealant and the glass plates. Set appropriate pressure and duration based on product requirements and equipment capabilities.

Set parameters: a. On the control interface of the sealing line, set relevant parameters, such as glass plate size, sealing speed, sealing width, sealing thickness, etc. Set parameters according to product requirements and process specifications. b. If using two-component glue, you need to set the glue ratio and mixing time.

Start the sealing robot equipment: a. Press the start button to start the sealing robot equipment. Ensure the safety of the insulating glass production line and wait for the sealing robot equipment to enter normal working conditions.

Automatic conveying of glass plates: a. Place the glass plate to be sealed on the conveyor belt or transmission mechanism to ensure that the position and positioning of the glass plate are accurate.

Automatic sealant sealing application: a. The sealing line will automatically apply sealant evenly to the edge of the glass plate or the parts that need to be sealed according to the set parameters. Ensure that the sealing robot equipment works stably and the glue is sprayed evenly.

Glass plate fixing: a. After the sealant is sprayed, the sealing line will fix another glass plate to be sealed on the glass plate that has been coated with sealant. Make sure the glass panels are aligned accurately and sealed tightly.

Sealant sealing and compression: a. The insulating glass sealing robot machine will perform a certain pressure treatment on the two glass plates to ensure a tight combination of the sealant and the glass plates. Set appropriate pressure and duration based on product requirements and equipment capabilities.

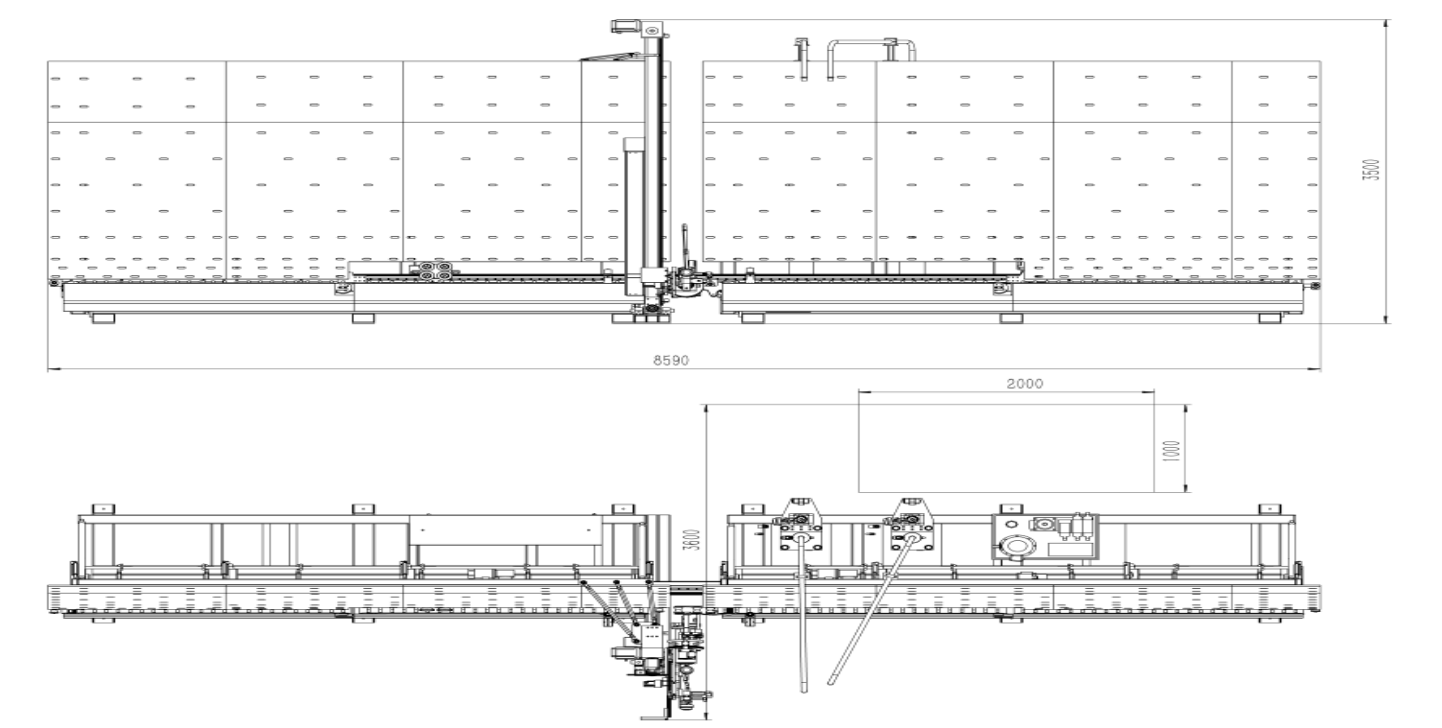

Parámetro técnico

| Item. | Spec. |

| Max. Glass Size | 2000*3000 mm/2500*4000 mm/3300*7000 mm |

| Min. Glass Size | 400*300 mm |

| Glass Thickness | 12-56 mm/12-56 mm/12-80 mm |

| Working Speed | 5-40 mm |

| Air Pressure | 0.6-0.8 MPa |

| Squeeze Pressure | <35 MPa |

| Voltage | 380V 50Hz 3P |

| Power | 15 Kw/15 Kw/20 Kw |

| Overall Dimension(L*W*H) | 3700*2500*3000 mm/8700*2500*3500 mm/ 15000*2500*4300 mm |

| Weight | 4300 kg/5000 kg/7000 kg |

Descripción técnica

Equipo de robot de sellado de vidrio aislado automático LJTJ2030/LJTJ2540 2

Equipo de robot de sellado de vidrio aislado automático LJTJ2030/LJTJ2540 2