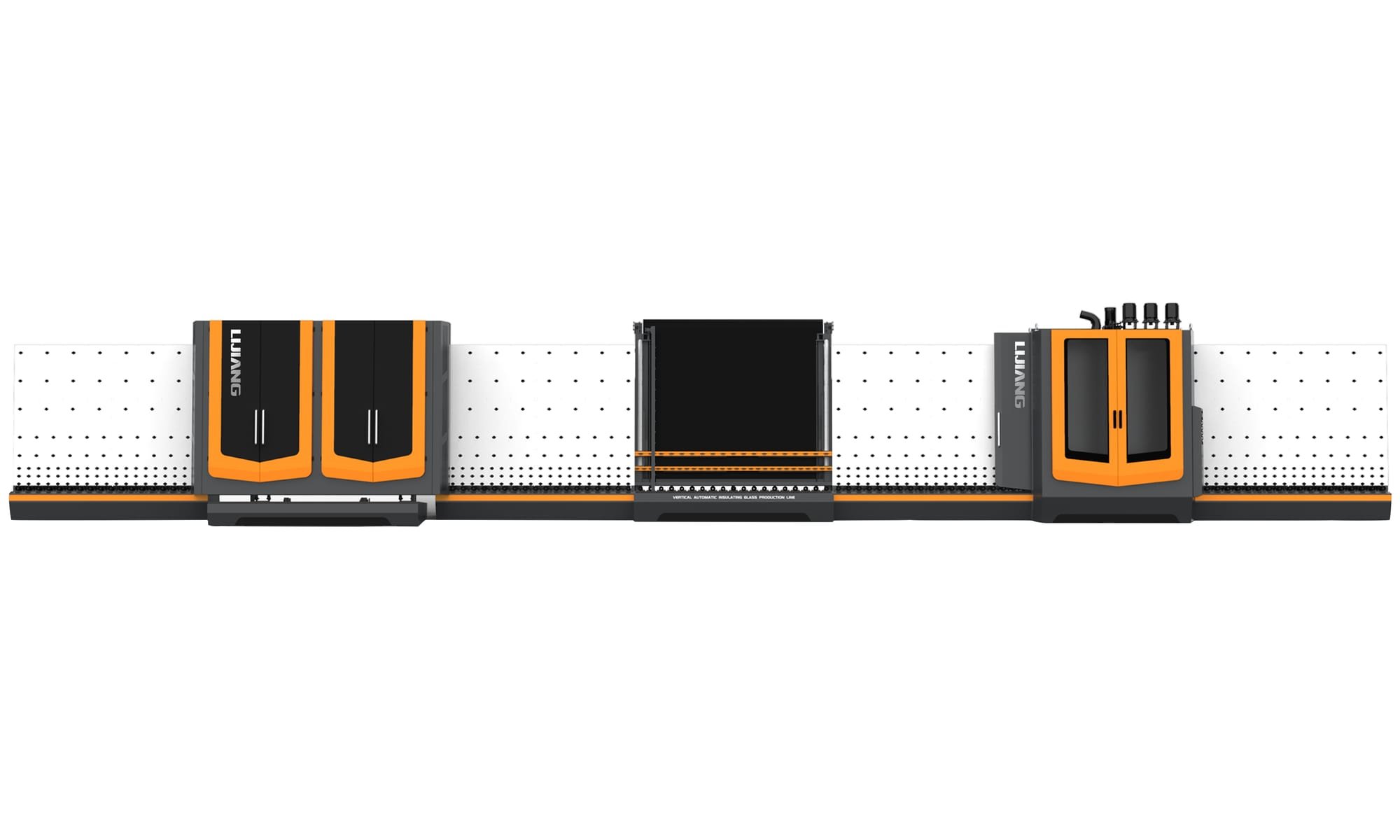

Línea de producción automática de vidrio aislante vertical

Vidrio LIJIANG

Más detalles de equipos automáticos

Principio de funcionamiento básico

- Sistema de control PLC Siemens de Alemania, interfaz de pantalla táctil para operación táctil con los dedos

- Identificación automática de vidrio revestido y vidrio Low-E;

- 3 pares de cepillos suaves pueden lavar vidrio de baja emisividad en línea y vidrio de baja emisividad fuera de línea;

- Las piezas de lavado adoptan material SS y dispositivo a prueba de agua;

- Tanque de agua con control automático de temperatura y sistema de lavado de agua.

- Sistema de calefacción de aire;

- Configuración automática de arranque y parada del ventilador de aire;

- Sistema de reducción de ruido;

- Visualización en línea de la velocidad de lavado;

- Trabajo intermitente inteligente, ahorro de energía;

- Tablero de presión ajustable para mantener recta la superficie de presión de la placa;

- Modo de conexión del enchufe de aviación;

- Aplicable para producir IGU triples e IGU con forma.

Pasos de trabajo detallados

- función de prelavado;

- Posicionamiento automáticamente preciso para DGU de 3 o 4 escalones laterales;

- El llenado automático de gas argón podría establecer el valor del gas y mostrar el proceso de llenado en línea con una alta concentración de gas.

Parámetro técnico

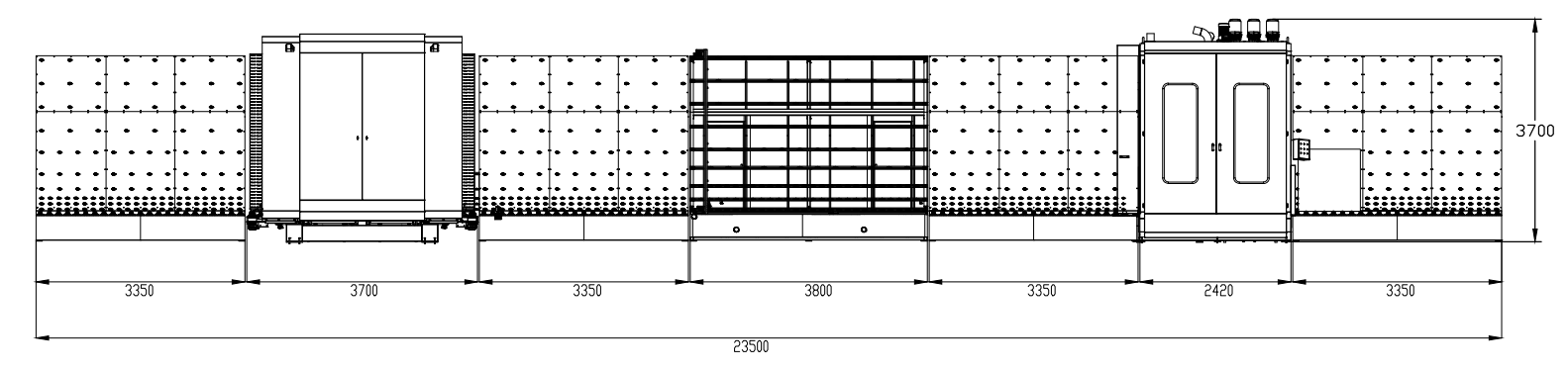

| Unit | LJBZ2030 | LJBZ2030G | LJBZ2535 | LJBZ2535G | LJBZ2535DG | |

| Voltage | 380V 50Hz 3P | |||||

| Total Power | Kw | 39.5 | 36 | 41 | 39.5 | 44 |

| Washing Speed | m/min | 2-10 | ||||

| Maximum Working Speed | m/min | 45 | ||||

| Minimum Glass Size | mm | 450*280 | ||||

| Maximum Glass Size | mm | 2000*3000 2000*3500 (Secondary Tableting) | 2500*3500 2500*4000(Secondary Tableting) 2500*4500(Secondary tablet pressing and auxiliary suction cup mechanism) | |||

| Flat Glass Thickness | mm | 3~15(Could be customized 3~30) | ||||

| Washing Brushes | pieces | 6 | ||||

| Maximum Thickness of Insulating Glass | mm | 60 | ||||

| Total Gas Consumption | L/min | 1200 | ||||

| Conveyer roll Height | mm | 520 | ||||

| Dimension L*W*H | mm | 20200*3500*3200 | 23800*3500*3700 | 27200*3500*3700 | ||

Descripción técnica