Guía de compra de máquinas cortadoras de vidrio automáticas

La Guía de compra de vidrio de LIJIANG está aquí para usted: allí encontrará nuestras recomendaciones para la última pregunta: ¿Qué tipo de máquina cortadora de vidrio automática o línea de corte de vidrio debería comprar? Hay una colección de guías de compra por categoría.

Los pasos de operación correctos de la máquina cortadora de vidrio.

Cuando utilizamos una máquina cortadora de vidrio automática, debemos verificar el vidrio a cortar con anticipación. En cuanto a la apariencia del vidrio, no podemos tener apariencia de manchas blancas y rayones. Solo después de calificar las condiciones más básicas se puede llevar a cabo la producción en masa. Al medir, la primera fila debe ser el objeto de medición y, si es necesario, se debe realizar una inspección completa.

Know More

¿Cuáles son las características de rendimiento de la máquina automática de corte de vidrio?

¿Cuántas características y ventajas tiene la máquina automática de corte de vidrio? Como debe saber un profesional senior en la industria de procesamiento de vidrio, simplemente desmonte todo el equipo de corte de vidrio y analice las características de rendimiento de la maquinaria de corte de vidrio desde la perspectiva mecánica, sistemas eléctricos y de control PLC...

Know More

¿Cómo elegir el equipo de la máquina automática de corte de vidrio?

Con el desarrollo del mercado del vidrio en algunos países en desarrollo, también se han desarrollado maquinaria y equipos de vidrio automatizados. Entre ellos, las máquinas de corte de vidrio han madurado gradualmente y hay innumerables fabricantes. Como empresa de producción de vidrio, ¿cómo debemos elegir el equipo de corte de vidrio que más nos convenga?

Know More

One article unlocks! Various application scenarios of architectural glass cutting table

Don't miss it! This article comprehensively shows how building glass cutting machines display their extraordinary capabilities and complete exquisite cutting in various building scenarios.

Know More

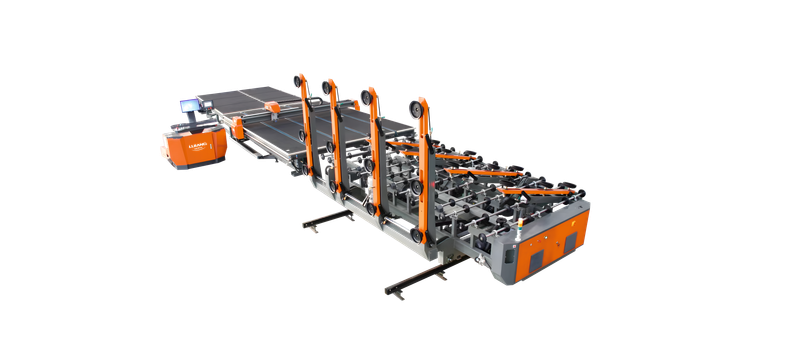

Automatic Glass Cutting Table | An Efficient Solution for Straight and Shaped Cutting of Float Glass

The automatic glass cutting table is a high-efficiency machine for straight and shaped float glass cutting. Its compact design fits workshops and production lines of any size. Equipped with CNC control and precision cutting technology, it handles glass from 2–19 mm thick with ±0.15 mm accuracy, ensuring smooth edges and precise dimensions. With automatic loading, layout optimization software, and fracture detection, it boosts production, lowers labor costs, and reduces waste. Ideal for architectural, appliance, curtain wall, or decorative glass, it offers a stable, efficient, and low-maintenance cutting solution.