How to optimize the layout of facilities for insulating glass production workshop.

Safety glass is a deep-processing product of ordinary flat glass. The most widely produced and used safety glass today mainly includes tempered glass, insulating glass, bulletproof glass, etc. There are various types and different production processes. At present, the safety glass production enterprises in some developing countries are still mostly small and medium-sized, and most of them are order-based production models. Many enterprises are limited by insufficient funds and talents, lack scientific management methods, and cannot improve product technology. Some facility layouts designed only based on production experience have become a bottleneck in improving the production efficiency of enterprises.

1. Current situation of enterprise production workshop layout

Taking the production workshop of a safety glass manufacturing enterprise in the service of LIJIANG Glass as an example, the layout of the workshop is mainly based on industry habits and the experience of engineers and enterprises, which is highly subjective and lacks a reasonable scientific analysis process. The layout of the production workshop currently exists a certain question, the main products produced by this enterprise are toughened glass and insulating glass, insulating glass is a reprocessed product of tempered glass, and the process flow is glass raw material storage, cutting, edging, drilling, tempering, and insulating.

2. Workshop layout optimization based on SLP system

2.1 Division of work units in the production workshop

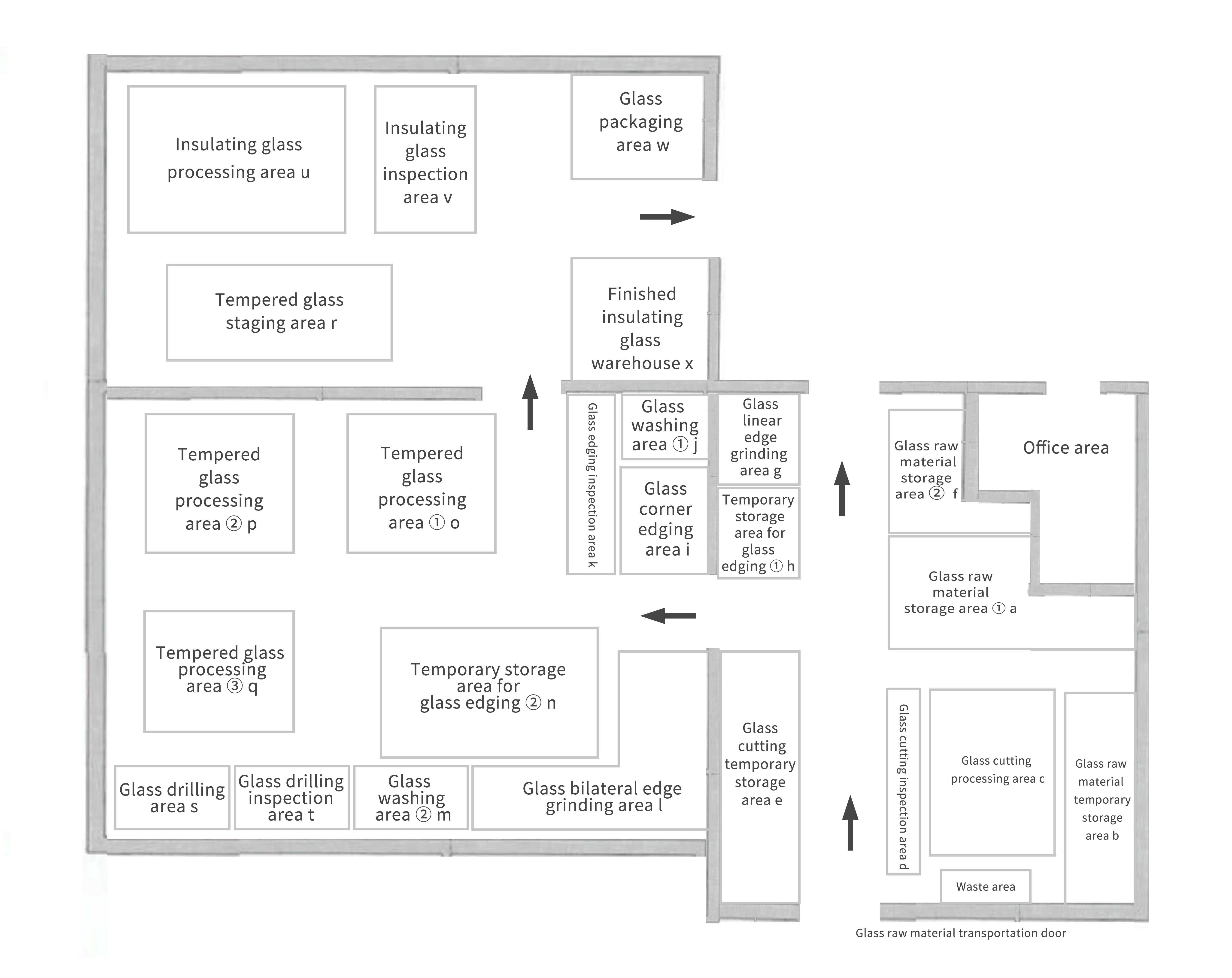

According to the product production process and the existing equipment and workshop area, the production workshop of this enterprise is divided into 24 main production sections, which are: raw material storage, raw material temporary storage, slicing, slice inspection, slicing temporary storage, raw material storage 2, straight line Edge grinding, edge grinding temporary storage 1, four corners edge grinding, clearing. Washing 1, edging inspection, bilateral edging, washing 2, edging temporary storage 2, tempering 1, tempering 2, tempering 3, tempering temporary storage, drilling, drilling inspection insulating, insulating inspection, packaging, warehouse.

2.2 Introduction to SLP logistics analysis methods

The SLP logistics analysis method is a stochastic planning method. It mainly plans the parameters such as the location, quantity, and path of each node in the logistics system to achieve the purpose of improving the efficiency of logistics operations. The core idea of this method is to reduce logistics costs and improve service levels through reasonable planning on the premise of meeting customer needs.

The practical application of the SLP logistics analysis method mainly includes the following steps:

- Step 1 : analyze the nodes in the logistics system. These nodes can be designated facilities, such as warehouses, distribution centers, etc., or temporary nodes, such as a certain area or road segment. Through the analysis of nodes, information such as the number, location, and capacity of nodes can be determined.

- Step 2 : analyze the route in the logistics system. The path is the line connecting each node, which determines the transportation route and transportation mode of the items in the logistics system. In the SLP logistics analysis method, the shortest path algorithm is usually used to calculate the path.

- Step 3 : Analyze the capacity in the logistics system. Capacity determines the storage and transportation capabilities of each node. In the SLP logistics analysis method, the linear programming method is usually used to optimize capacity allocation.

- Step 4 : analyze the random factors in the logistics system. There are many random factors in the logistics system, such as traffic congestion, weather changes, etc., which will affect the logistics operation. In SLP logistics analysis methods, probability theory and statistical methods are usually used to consider these random factors.

2.3 Analysis of the logistics relationship of the operation unit

The production workshop of this enterprise is arranged according to the product, its logistics route is relatively simple, and the monthly equivalent logistics volume of each operation unit is counted to determine the logistics handling route. SLP can divide the degree of logistics interrelationship between operation units into five grades: A, E, I, O, and U. Grade A represents ultra-high logistics intensity; grade E represents high logistics intensity; grade I represents relatively high logistics intensity; grade O Indicates general logistics intensity; grade U indicates negligible handling. According to the proportion of the equivalent material flow, arrange from more to less, compile the operation unit logistics relationship table and the operation unit logistics correlation diagram, which can reflect the use weight and logistics information of each operation unit of the enterprise in the form of charts, which is an intuitive reflection of the enterprise scientific method of production process.

2.4 Analysis of the non-logistics relationship of the operation unit

In the process of facility planning, there are other factors such as the continuity of the process flow, the frequency of personnel contact, the similarity of the nature of the operation, the convenience of material handling, the impact of noise and sanitation, etc. among the various operating units. These factors can be called Non-logistics factors between various operation units. According to the SLP theory, the non-logistic relationship between each operation unit can be divided into six. According to the actual production status of the enterprise, the logistics relationship (m) is slightly greater than the impact of the non-logistics relationship (n), so the relative importance ratio is determined as m:n=2:1

The values of logistics intensity level and non-logistics closeness level are A-4, E-3, I=2, 0=1, U-0, X=-1

According to relation:

TRij=mMRij+nNRij calculates the comprehensive interrelationship value, where TRij is the comprehensive interrelationship between two operating units, MRii is logistics correlation, and NRij is non-logistics correlation.

Take m=2, n=1, and correspondingly transform into six grades of A, E, I, O, U, X, and the TRij value between each grade gradually decreases. According to this method, the statistical calculation is carried out, the comprehensive relationship level is determined, and the comprehensive correlation diagram of each operation unit can be made. This is the basis for the arrangement of facilities after comprehensive consideration. It not only combines logistics analysis but also combines the influence of non-logistics factors, which can scientifically effectively link facility and workforce planning.

The connection of these factors in the production line can be represented by the non-logistics correlation diagram of the operation unit, which is a supplement to the logistics analysis and allows the consideration of the facility planning to be more comprehensive.

2.5 Production workshop layout plan

According to the comprehensive analysis results of the workshop operation unit, combined with the actual material import and export positions of the glass deep processing production workshop, the layout scheme is obtained as shown in Figure 1.

Figure 1 The glass processing production workshop layout plan

3. Conclusion

LIJIANG Glass used the SLP method to conduct qualitative research on the layout of its production workshop by analyzing the production status and workshop layout status of a safety glass company within one month of production orders and proposed a feasible layout plan. Among them, the layout planning of the workshop can use the automaitc glass intelligent storage system to organize and cache the glass before insulating, and meet the requirements of automatic pairing and output of insulating glass A/B pieces, and input scattered glass into the roadway for fast and accurate detection and intelligent system. Comparing and optimizing, the film is produced according to the rules of the frame arrangement mode instead of manual matching and ordering, thereby improving the overall production efficiency of the glass deep-processing enterprise.

For more information about Jinan LIJIANG Glass insulating glass processing equipment and insulating glass processing accessories, please click here to learn more.