The Selection of PVB Coating Thickness for Laminated Glass: A Guide for New Practitioners.

Safety, high quality, green, and low-carbonization have become the main tone of development in the new stage. The safety, green, low-carbon, and energy-saving of doors, windows, and curtain walls require further upgrading of their supporting materials. As the most widely used modern surface material in architecture, glass has been highly praised by real estate, owners, and architects in door, window, and curtain wall projects. However, frequent safety accidents such as glass breakage and falling, tempered glass self-explosion, etc. have made the whole society attach great importance to the safety application of glass. For plastic glass, after the inner and outer layers of the glass are damaged, whether there will be more secondary hazards depends on the function of the glass interlayer film. At the same time, safety glass and ultra-clear glass have become the first choice for super high-rise buildings and commercial landmarks, and the "film" between glass and glass has become the key. So, how to choose the thickness of the laminated glass PVB film? Next, LIJIANG Glass will share with you the relevant guidelines for the glass deep processing process:

Figure 1 The PVB coating for laminated glass 1

1. Scope of application:

Applicable to conventional ordinary laminated glass, flat tempered and heat-strengthened laminated glass, bent tempered or bent heat-strengthened laminated glass, and hot-bent laminated glass.

2. PVB selection criteria

2.1 Ordinary laminated glassOrdinary laminated glass means that the substrate of laminated glass is annealed float glass, excluding bulletproof glass, aquarium glass, and multilayer laminated glass.The thickness of ordinary laminated glass PVB is selected according to the following table:

| Glass type | Substrate glass thickness (mm) | PVB film thickness (mm) | |

| Short side≤800mm | Short side > 800mm | ||

| Ordinary laminated glass | ≤6mm | 0.38 | 0.38 |

| 8mm | 0.38 | 0.76 | |

| 10mm | 0.76 | 0.76 | |

| 12mm | 1.14 | 1.14 | |

| 15mm, 19mm | 1.52 | 1.52 | |

Note:

- The thickness of the substrate glass is selected based on the thickness of the thicker substrate in the laminated glass, and the surface quality of the substrate must meet the corresponding float glass standards.

- Bulletproof glass must be inspected and recorded for the record, and its PVB thickness must follow the standard type and cannot be changed.

- Aquarium glass and multi-layer laminated glass need to analyze and scientifically calculate the thickness of PVB film according to the specific situation due to their stress condition and complex structure, so I won’t go into detail here.

2.2 Flat-tempered and heat-strengthened laminated glass

Tempered or heat-strengthened interlayer products, due to the inevitable glass wave and bow deformation during the tempering process, the gaps between the glass caused by this deformation will be filled by PVB film.The standard for deformed interlayer should not exceed 3‰.The selection of PVB thickness for flat-tempered and heat-strengthened laminated glass follows the rules in the table below:

Types of laminated glass | Substrate glass thickness (mm) | PVB film thickness (mm) | ||

Short side≤800mm | 800mm short side≤1500mm | Short side > 1500mm | ||

| Flat-tempered, heat-strengthened laminated | ≤6mm | 0.76 | 1.14 | 1.52 |

| 8~12mm | 1.14 | 1.52 | 1.52 | |

| ≥15mm | 1.52 | 2.88 | inated glass equipment should be used Carry out glass PVB coating. | |

Note:

- For flat-tempered and heat-strengthened laminated glass, if the difference in thickness between the two pieces of glass is more than 3mm, this structure is not recommended due to an unreasonable stress structure. If you insist on using it, the thickness of PVB must be increased by 0.38mm based on the corresponding regulations.

- For single-piece tempered or heat-strengthened laminated glass, due to the unstable factors of thermal cracking and the unreasonable stress structure, it is not recommended to use this structure. If you insist on using it, the thickness of PVB must be increased by 0.38mm based on the corresponding regulations, and you will not be responsible for the breakage of non-tempered or heat-strengthened glass.

- For special-shaped tempered and heat-strengthened laminated glass, since the edge of the special-shaped glass will cause large deformation, the thickness of PVB must be increased by 0.38mm based on the corresponding regulations.

- For flat-tempered and heat-strengthened laminated glass, when the high side and wide side of the glass are both greater than 800mm, and the ratio is close to 1, it is difficult to control the glass waveform when tempering or heat-strengthening glass of this size, and large deformation will occur, PVB thickness must be increased by 0.38mm based on the corresponding regulations.

- The thickness of the substrate glass is selected according to the thickness of the thicker sheet in the laminated glass substrate.

2.3 Bending tempered, heat-strengthened laminated glass and hot-bending laminated glass

Curved tempered laminated glass is increasingly used in buildings due to its unique structural form and good safety performance, but it also brings many problems. A lot of curved tempered laminated glass has the phenomenon of glue opening and air bubbles at the edge soon after the project is completed, which has brought huge losses to both the manufacturer and the owner.Bending tempered and heat-strengthened laminated glass has radians in the glass itself, and its radian error and tempering deformation determine that the thickness of the PVB film in the middle is thicker than that of ordinary laminated glass, and the minimum thickness is 2.28mm.The selection of bent tempered, heat-strengthened laminated glass, and heat-bent laminated glass PVB follows the rules in the table below:

| Types of laminated glass | Substrate glass thickness (mm) | PVB film thickness (mm) | |

| Curvature radius R>3m | The radius of curvature R≤3m | ||

| Heat-tempered, heat-strengthened laminated glass | ≤8mm | 2.28 | 3.04 |

| ≥10mm | 3.04 | 3.04 | |

| Hot bending glass | ≤6mm | 0.76 | 1.14~1.52 |

| ≥8mm | 1.14 | 1.52 | |

Note:

- The thickness of the substrate glass is selected according to the thickness of the thicker sheet in the laminated glass substrate.

- Bent-tempered and heat-strengthened glass must meet the corresponding processing requirements for bent-tempered glass.

- The hot-bending glass must meet the corresponding hot-bending glass processing requirements.

PVB laminated film 2023 recommended film brand

Laminated glass has the advantages of strong anti-intrusion performance, explosion-proof, anti-theft, fire prevention, anti-UV, and beautiful appearance, etc. It is suitable for super high and super large construction projects, terminal buildings, venues, commercial centers, and other safety glass.

Figure 2 The PVB coating for laminated glass 2

After analyzing the mainstream film product types in the market, LIJIANG Glass found that each has different advantages and disadvantages. In terms of strength alone, SGP ionomer film laminated glass has higher bending strength than PVB film laminated glass. Ultra-clear glass has higher permeability and visual effect after compounding. At the same time, PVB and SGP films are mainly used for curtain wall glass, while EVA films are mostly used for interior decoration.

Figure 3 The PVB coating for laminated glass 3

Among them, the quality and craftsmanship of the film determine the final quality of laminated glass. At present, the upstream and downstream of the industry present a clear "polarization". The application of intelligent technology has become more popular, and the scale and output value of leading enterprises have steadily increased.In the market, from the appearance (color and pattern) of the film, with the improvement of the laminated glass equipment and the technical level and proficiency of the practitioners, the quality of the film is guaranteed.From the analysis of the yield rate, whether it is processing equipment or employees, the overall level of the industry has improved significantly, and the vast majority of film applications have basic guarantees. The performance scope and items of national standards and inspection standards are aimed at the wide-area concept in the industry. The products of most enterprises can pass the inspection safely, and the gap is not large. The second thing that should be paid attention to in performance is "weather resistance performance". Because of its particularity, it cannot be reasonably detected or evaluated within a certain period, and a more complete market response plan is required in the future.According to the "five elements" of enterprise evaluation, LIJIANG Glass will bring you the recommended brand information about "glass interlayer film" that mainly serves the door, window, and curtain wall industry.

Element 1: Brand effect (brand value)

A brand is to increase market share and reflect the core "values" of high-quality products. Excellent products must have a higher brand effect. Simple "high investment" does not equate to high brand value. The key is to have a professional team and case support.

Element 2: Innovation and research ability (quality craftsmanship)

The material and technology of the film are the core competitiveness, and the production and research and development capabilities become an important "threshold". Specific indicators: product appearance (transmittance, color, etc.), production equipment, technology level, research and development capabilities, and one-time yield. Medium and large-scale manufacturers with advanced production lines have completely outperformed "small factories".

Element 3: Market Positioning (Product System)

The quality requirements of building doors, windows, and curtain walls are increasing day by day. Product positioning is based on the characteristics and needs of glass applications in the project, and the product characteristics of the film are fully utilized. With the help of national standard testing (including weather resistance, etc.), the material, characteristics, and functions must meet the needs of current applications...

Element 4: Sales network (layout capability)

The sales network and channel development are the key links to control the market development, and also undertake the main link between the enterprise and the upstream and downstream, and are the lifeblood of the enterprise's survival. The market of glass laminated film is mainly based on industry and construction, so in cooperation, more outlets are set up in cities and regions where glass deep processing is concentrated.

Element 5: service system (after-sales structure)

The pre-sale, sale, and after-sale services are reflected in the whole life cycle of the building, including the refinement of the building plan in the early stage, the guidance of processing and assembly, and the inspection of the installation and commissioning stage, etc. must form a platform service. To establish a modern data terminal and a front-end service team, it is not only necessary to meet the product structure of the project requirements but also to achieve rapid updates and rapid maintenance.

Figure 4 The PVB coating for laminated glass 3

In the door, window, and curtain wall industry, in addition to focusing on door and window products and curtain wall systems, more attention is also extended to glass products, one of the core accessories. " as the entry point, presenting the market's preferred high-end glass laminated film brands in 2023.

Next, LIJIANG Glass made full use of the "five elements" evaluation system and made comprehensive judgments based on foreign brands, joint venture brands, domestic brands, and the main direction of innovation and research capabilities. Carry out detailed brand recommendations for glass interlayer film, make the industry more interconnected, and improve the brand system of the industrial chain.——Glass Laminated Film PVB——The PVB film is degraded and synthesized under high pressure, and high temperature, and becomes transparent from opaque. Therefore, PVB laminated glass has good safety, sound insulation, and UV resistance, but PVB has poor water resistance, and it is easy to fall off after long-term wet immersion. At the same time, it is often said in the industry that PVB film is not like tempered glass, which will shatter when hit. up. 7-8 years ago, PVB film was mainly imported, and domestic PVB has developed rapidly in recent years.

No 1, DoPont

Manufacturer: DuPont de Nemours, Inc.,

Recommended reason: DuPont is the world's leading supplier of polyvinyl butyral (PVB-) safety interlayers, and is the only manufacturer to provide high-quality PVB-interlayers, available in virgin (Butacite®) or 100% post-industrial recycling ( Butacite® G) material.In architectural applications, DuPont™ Butacite® and Butacite® G PVA interlayers offer similar safety advantages in retaining hazardous shards in the event of glass breakage. They are widely used safety glass interlayers throughout the world and are available in clear, translucent white and several other popular solid shades for aesthetic effect or control of light transmission.

Brand effect: ★★★★★

Research ability: ★★★★★

Project case: ★★★★☆

Sales network: ★★★★☆

Team Service: ★★★★★

Recommended index: ★★★★★

Enterprise Positioning: International

No 2, SekiSui

Manufacturer: Japan Sekisui Chemical Industry Co., Ltd.

Reasons for recommendation: S-LEC™ Film is an interlayer film that is sandwiched between architectural laminated glass and exerts various properties. More and more glass is used in modern buildings. How to use glass to create a safer and more comfortable living space and achieve a richer sense of architectural design is a trend that must be paid attention to as an interlayer film product. In addition to safety interlayers, S-LEC™ Film also has high-performance interlayers with enhanced performance and decorative interlayers. Sekisui's membrane production technology brings more functions to glass and meets the various needs of today's buildings.

Brand effect: ★★★★☆

Research ability: ★★★★★

Project case: ★★★★

Sales network: ★★★★★

Team service: ★★★★☆

Recommended index: ★★★★☆

Enterprise Positioning: International

No 3, Australia Tough Glass

Manufacturer: Australia Tough Glass Co., Ltd.

Reason for recommendation: Tough Glass was established in 2010 and has built an excellent reputation over the years, to now become one of the leading glass processing companies in Australia. Tough Glass is one of the few manufacturers in the industry that has PVB raw material resin powder. Tough Glass continually invest in the latest state-of-the-art production equipment. With increased productivity and quality workmanship combined, and they deliver their products and services to the highest standards of quality in a controlled environment.

Brand effect: ★★★★☆

Research ability: ★★★★

Project case: ★★★★

Sales network: ★★★★★

Team Service: ★★★★

Recommended index: ★★★★☆

Enterprise positioning: domestic

No 4, PFG Glass

Manufacturer: PFG Glass Industries Ltd.

Reasons for recommendation: A brand that focuses on the production, sales, and innovative research and development of polyvinyl butyral (PVB) interlayer films. The company's PVB products are widely used in many fields such as construction, automobiles, photovoltaics, aerospace, and national defense. The brand is committed to serving high, medium, and low-end customers at home and abroad. The production capacity and sales have been growing steadily. The "PFG Glass" brand has been widely recognized by the industry.

Brand effect: ★★★★

Research ability: ★★★★

Project case: ★★★★

Sales network: ★★★★★

Team Service: ★★★★

Recommended index: ★★★★☆

Enterprise positioning: domestic

No 5, Everlam

Manufacturer: Everlam NV

Reason for recommendation: EVERLAM makes high-quality Polyvinyl Butyral (PVB) film for architectural laminated safety glass. Building on its plant’s 25 years’ experience and reputation for consistent quality and its unequalled technical support, EVERLAM is committed to collaborating with customers worldwide to deliver the best PVB interlayer and service support.The company invests heavily in R&D and production capacity and is expanding to become a major player on the architectural laminated safety glass market.

Brand effect: ★★★★

Creation and research ability: ★★★★☆

Project case: ★★★★

Sales network: ★★★★

Team service: ★★★★☆

Recommended index: ★★★★

Enterprise positioning: domestic

No 6, Eastman (Saflex)

Manufacturer: Eastman Chemical Co., Ltd.

Recommended reason: Eastman is a global specialty chemical company that produces a broad range of products found in items people use every day. With a portfolio of specialty businesses, Eastman works with customers to deliver innovative products and solutions while maintaining a commitment to safety and sustainability. Its market-driven approaches take advantage of world-class technology platforms and leading positions in attractive end-markets such as transportation, building and construction, and consumables. Eastman focuses on creating consistent, superior value for all stakeholders. As a globally diverse company, Eastman serves customers in approximately 100 countries. The company is headquartered in Kingsport, Tennessee, U.S.A

Brand effect: ★★★★

Creation and research ability: ★★★★☆

Project case: ★★★★

Sales network: ★★★★☆

Team service: ★★★★☆

Recommended index: ★★★★

Enterprise positioning: domestic

No 7, Genau PVB

Manufacturer: Genau Manufacturing Company LLP (GMC LLP)

Reasons for recommendation: Genau Manufacturing Company LLP (GMC LLP) is the first and only manufacturer of PVB in India. We are the leading experts in this industry and popular as a global producer for the laminated glass applications in photovoltaic, architecture industries.

Brand effect: ★★★★

Creativity and research ability: ★★★★☆

Project case: ★★★★

Sales network: ★★★★☆

Team service: ★★★★☆

Recommended index: ★★★★

Enterprise Positioning: Domestic

Glass interlayer film is often easily overlooked. In the building door, window, and curtain wall industry, most parties and engineering companies only pay attention to glass quality and price. In the past, although the market ignored these small links and only saw the overall project effect there are subtleties in every small link.First of all, the film will affect the look and feel of the facade of the building, mainly including the effect of the glass panel brought by the color, pattern, etc; secondly, the one-time yield of the film and the performance identification of the national standard verification standard are the guarantees of the quality of laminated glass. Prerequisites; Then there is the weather resistance, because the film is a "hidden material", and the weather resistance needs time to test. Once the bubble rebounds or the degumming turns yellow, the laminated glass will not be saved.In addition, LIJIANG Glass will also provide relevant recommendations for glass deep processing practitioners on automatic laminated glass lamination furnaces.

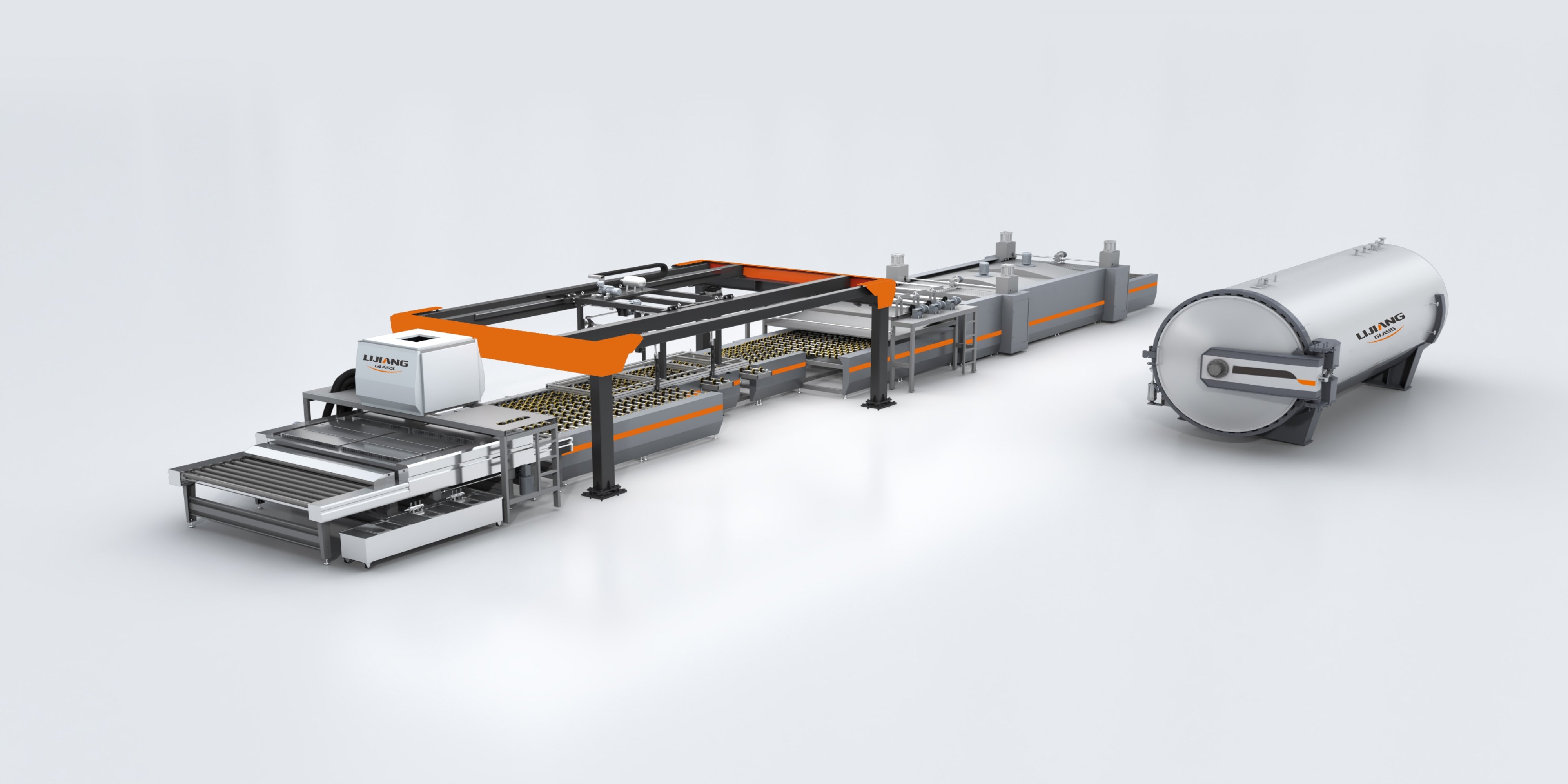

Figure 5 The LIJIANG Glass automatic laminated glass lamination furnaces

Therefore, weather resistance has also become a key criterion to distinguish the quality of products currently on the market, and having enough project cases has become the core support of brand power. In the future, LIJIANG Glass will also conduct in-depth investigations and interviews on the architectural glass industry to learn more about the market brands and corporate performance of the "film" industry chain, display relevant information, and focus on technologies and products in this subdivided field. Organize and analyze the development direction, and provide professional purchase guides and application recommendations for upstream and downstream enterprises.

For more information about LIJIANG Glass insulating glass production line and insulating glass processing equipment, please click here to learn more