Research on energy-saving technology of glass tempering equipment.

The rapid development of science and technology has brought a variety of technologies into the public, and glass tempering technology is one of the representative products. Glass tempering technology can be traced back to around 1930. After more than 80 years of development, related technologies have gradually become mature. Glass tempering is a follow-up process. If there are any problems or defective products in the tempering stage, it will inevitably affect the cost of investment. Therefore, high attention should be paid to the process of glass tempering. To better meet the current needs of the relevant tempered glass production, manufacturers have begun to actively explore energy-saving technologies, combined with the current sustainable development strategy proposed by the country, advocate the use of more ideal key measures, and formulate reliable measures to ensure better production results.

1. The specific method of glass tempering

The glass tempering method is based on the actual need to make a scientific choice, combined with the specific requirements of glass tempering to judge, to ensure that the selected method conforms to the actual situation, and can achieve ideal life, production, and various goals. The most critical point of glass tempering is to reasonably change the mechanical properties of the glass itself and broaden the scope of use. The basic principle of glass tempering is that after the glass is properly heated and cooled, the tensile stress of the glass itself is reflected, and the corresponding compressive stress is generated on the surface to achieve the ideal effect. The whole process of glass tempering, has effectively improved its safety performance and strengthened its strength, and its thermal stability is very ideal, which can meet the actual needs of different aspects of life. Glass tempering methods cover both chemical and physical types. The working principle of physical tempering is to use the heat transfer medium to complete the heating treatment of the glass material, and properly present the state of extremely rapid cooling in the cooling medium, to obtain a more reliable tempering effect. Chemical toughening uses chemical means to change the composition of the glass surface reasonably, so that the compressive stress of the glass itself can be gradually increased, thereby promoting a steady change in its mechanical properties. Compared with physical tempering methods, chemical tempering can effectively consolidate the performance of the glass itself, avoid obvious deformation problems, and be more ideal in quality. However, chemical tempering is less efficient and involves higher costs.

2. Energy-saving ideas for glass tempering equipment

With the gradual increase in people's awareness of energy saving, the process of producing tempered glass should incorporate energy-saving ideas, attach importance to scientific and reasonable energy-saving ideas, and ensure that the glass tempering equipment can meet the ideal energy-saving standards. The heating process is used to make the heat absorption of the glass relatively uniform. To achieve the goal of energy saving, the system can be used to complete basic operations. In work practice, it is necessary to pay attention to scientific energy-saving ideas, steadily improve the production efficiency of glass tempering equipment, and ensure a better energy-saving effect.

2.1 Optimize the structure and process of the heating section

The uniform heating of tempered glass is an important subject, and the heating parameters need to be scientifically controlled. The new generation of glass tempering equipment significantly improves the heating efficiency and reduces the production energy consumption of tempered glass by optimizing the laying structure of machinery and thermal insulation materials and improving the production process.

2.2 Optimize the structural layout of the cooling section

The cooling of glass tempering is an important step, which can have a direct impact on the quality and strength of tempered glass. In the actual research of the new generation of equipment, the change of the tempered cold air temperature field and the blowing field has become the target of attention. Using scientific and reasonable tempering and cooling process separation schemes, with the help of optimizing the structure of the cooling zone, the tempered glass production stage reflects the ideal.

2.3 Optimize heating and cooling control system

With the popularization of laser infrared temperature measurement technology for civilian use, the application of advanced laser infrared temperature measurement technology to the heating control system of glass tempering equipment can realize real-time monitoring of the surface temperature of tempered glass during the production process. On this basis, combined with in-depth research on the parameters of the PID control system, a corresponding and more advanced heating control system has been developed, which not only greatly improves the heating efficiency, but also improves the uniformity of the tempered glass surface temperature during the production process, while effectively reducing production energy consumption, it has laid a solid foundation for the further improvement of tempered glass quality.

3. The energy-saving technology of glass tempering equipment

Today, with the obvious improvement of the technical level, glass tempering technology has been rapidly promoted. With its advantages, it has become the focus of attention. In the current practical application, the horizontal roller-type glass tempering equipment has become the mainstream of the market, which is of great help to the production of tempered glass and reflects extremely high utilization value. In addition to heating larger glass, it can better adapt to the requirements of different products. The glass tempering equipment contains many important components. The basic heating method is full electric radiant heating, and the basic source of heating is electric heating elements. Continuously improving the production process structure and control system level of glass tempering equipment can effectively improve production efficiency, reduce the heat loss of glass tempering equipment itself, and reduce production energy consumption, to achieve the goal of energy-saving and consumption reduction.

3.1 Optimize the combination of thermal insulation materials

Traditional glass tempering equipment chooses at most 1~2 kinds of insulation materials. The main consideration in the selection of insulation materials is to keep the inside of the furnace clean and prevent slag from falling out. For the goal of improving the insulation effect, the thickness of the insulation material is adjusted. However, there are few studies on thermal insulation efficiency. If the insulation material is thickened blindly, the equipment will have a large shape and high cost. Therefore, the thickness of the insulation material should be controlled within an acceptable range, and the insulation effect will be average. To ensure the smooth realization of the energy-saving goal, different thermal insulation materials should be reasonably combined and applied, using the characteristics of the lowest thermal conductivity of different thermal insulation materials in different temperature ranges, select 3 to 5 kinds of thermal insulation materials in the glass tempering equipment. The temperature range of the level in the production process, these kinds of insulation materials are arranged in an orderly manner from the inside to the outside of the tempering equipment, so that the performance of each insulation material can be maximized, which can not only save the number of insulation materials, but also reduce Equipment cost, and effectively control the heat dissipation of the glass tempering equipment itself, reducing production energy consumption.

3.2 Multi-station heating technology in the furnace

This technology has a very obvious utilization value, and the actual energy-saving effect is very significant when it is used in practice. The heating furnace body section of the glass tempering equipment includes several stations determined along the length of the furnace body. Different areas are formed according to specific specifications. The basic operations can be completed within a specific period by swinging back and forth in the area. After a specific temperature, it will be transferred to the subsequent stations in time. The production process of the tempering furnace is significantly different, and the difference in structure is very obvious, but the specific furnace temperature is the same. Multi-station glass tempering equipment needs to reasonably control the temperature difference in the furnace within a specific range to avoid the problem of glass bursting in the tempering furnace. Appropriately reducing heat loss is of great help to scientifically achieve the purpose of energy saving and emission reduction, and also makes the basic results of tempered glass more ideal. The application of multi-station technology in some tempering furnaces with specific structures, such as equipment with a heating section that is much longer than the cooling section, can significantly increase the speed of glass tempering production to about 1 to 2 times, compared to the traditional production process, production energy consumption has been reduced by more than 45%.

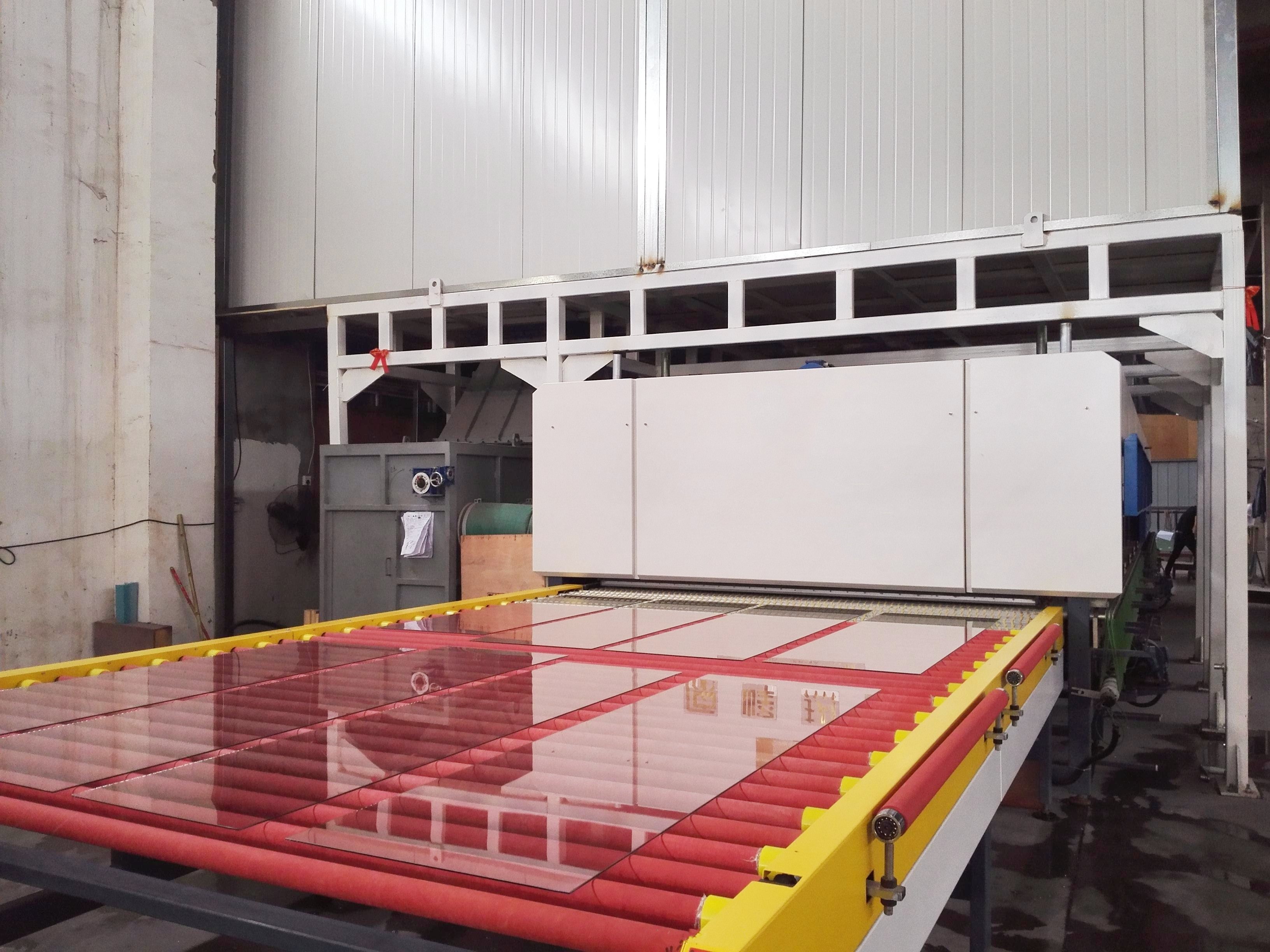

Figure 1 The multi-station heating technology in the furnace

3.3 Thermal Broken Bridge Technology

The components used for heating and convection in the glass tempering equipment, such as furnace wires, heating fans, etc., are placed inside the heating furnace body and fixed on the outer frame of the furnace body through a mechanical connection structure. This connection is equivalent to establishing multiple heat transfer channels inside and outside the furnace body, which leads to the continuous and rapid transfer of heat in the heating furnace body to the outside of the furnace body along with the connecting pieces, which greatly increases the heat loss of the glass tempering equipment. Therefore, in the structural design of glass tempering equipment, the first thing is to minimize the connection channel between the parts in the heating furnace and the external frame. Secondly, for the external connection structure necessary for high-temperature fans and furnace wires, it is necessary to reasonably increase the air partition structure, Parts made of non-metallic materials such as ceramics and other materials with low thermal conductivity, thereby blocking the transfer of heat from the inside to the outside. Compared with traditional tempering furnaces, the application of thermal break bridge technology can significantly reduce the surface temperature of the heating furnace body, reduce heat loss, and reduce production energy consumption by 10%.

3.4 Analysis and optimization of cooling section structure with advanced professional fluid software

With the gradual reduction of hardware requirements for temperature, fluid, and other software and the gradual strengthening of analysis capabilities, with the help of simulation analysis of professional temperature and fluid software, the temperature field and cooling airflow diagram of the entire cooling section are simulated. Multi-layer arc-shaped grid plates are arranged at the junction of the heating section and the cooling section, and the arc-shaped plates of each layer are arranged at equal intervals and in a structure of equal height difference to guide the airflow in the boundary layer of the glass surface in an orderly manner, effectively preventing the disturbance of the cold air to the heating temperature in the tempering furnace overcomes the defect of "inverting air" from the cooling section of the traditional glass tempering equipment to the heating section.

Optimize the blowing angle and the arrangement of the air holes, and at the same time design the cross-section of the bellows into a streamlined structure, which ensures that the blowing quickly tears the hot air boundary layer on the glass surface, improves the blowing efficiency, and accelerates the heat discharge from the glass surface. With these improvement and optimization measures, compared with the traditional tempering furnace, the glass cooling efficiency is significantly improved, which provides a guarantee for the production of high-quality glass tempering and energy saving and consumption reduction, and the energy consumption of the cooling section is reduced by 15%.

3.5 Intelligent Control Technology

To better achieve the purpose of energy-saving and achieve the ideal energy-saving demand, we should pay attention to the application of advanced technology in our work. The application of laser infrared temperature measurement technology in glass tempering equipment provides a technical guarantee for accurate and real-time monitoring of glass surface temperature. Based on this technology, a more advanced temperature control module is adopted, combined with in-depth research on PID parameters in the actual production process, through a reasonable and scientific intelligent control process, according to the actual production process glass varieties, specifications, and equipment loading rate. It is necessary to timely and accurately control the heating time, adjust the healing power of the upper and lower sides of the heating furnace and different areas, and adjust the proportion of fan convection heat transfer in the glass heating process.

The heat absorption is more symmetrical and uniform, which makes the glass layout relatively flat and truly achieves the purpose of ideal and uniform heating. The scientific application of this technology can promote heating efficiency to a new height and level, and harvest more complete energy-saving benefits.

4. The conclusion

To achieve the purpose of energy saving and emission reduction, the manufacturing industry should use high-efficiency and energy-saving technology in the glass tempering production stage, and appropriately use various schemes such as convection heating system and self-heating convection circulation system in the furnace, to make the glass tempering heating more uniform and achieve an ideal Energy saving and consumption reduction goals to ensure that the equipment application results are more significant. This article interprets the energy-saving ideas of glass tempering equipment in detail and further elaborates and analyzes the specific energy-saving technologies, aiming to provide reliable reference opinions for the majority of the industry and provide an effective reference for the long-term development of the glass tempering industry.

For more information about LIJIANG Glass insulated glass production line and insulated glass producing machine, please click here to learn more.