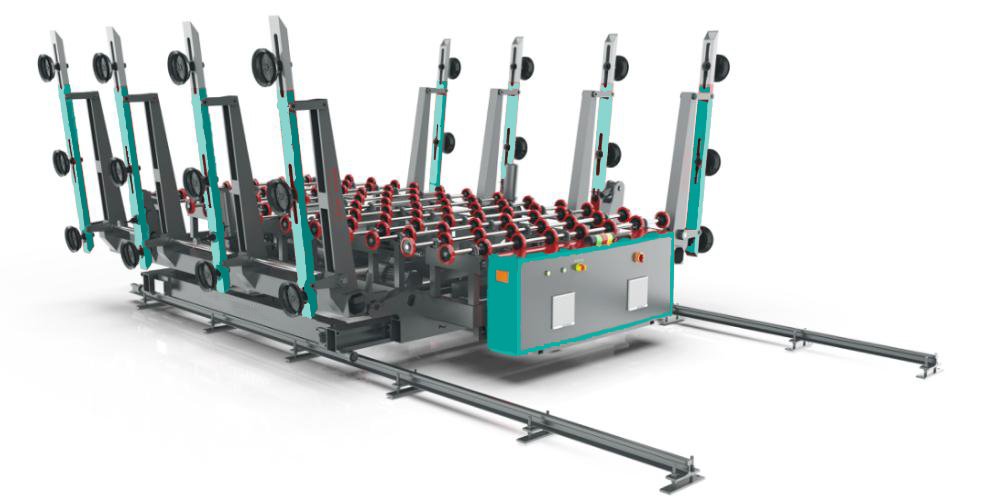

Automatic Glass Cutting Loading Table

LIJIANG Glass

Basic Working Principle

It is mainly used for automatic glass loading. After putting the glass in the designated position and giving the signal of loading, the big arm turns up about 95 degrees through the overturning mechanism, and the whole machine starts to move forward. When the induction device on the small arm touches the glass, the whole machine stops walking and the glass is sucked by the suction cup through the vacuum system on the glass,small arm lifting motor lifts the glass upward and backward about 80 mm. The walking motor retreats and the big arm falls down. When the bring arm is in place, the suction cup under the glass begins to blow. When the small arm falls down, the glass falls on the conveyor wheel. Finally, the glass is conveyed to the cutting table by the conveyor wheel.

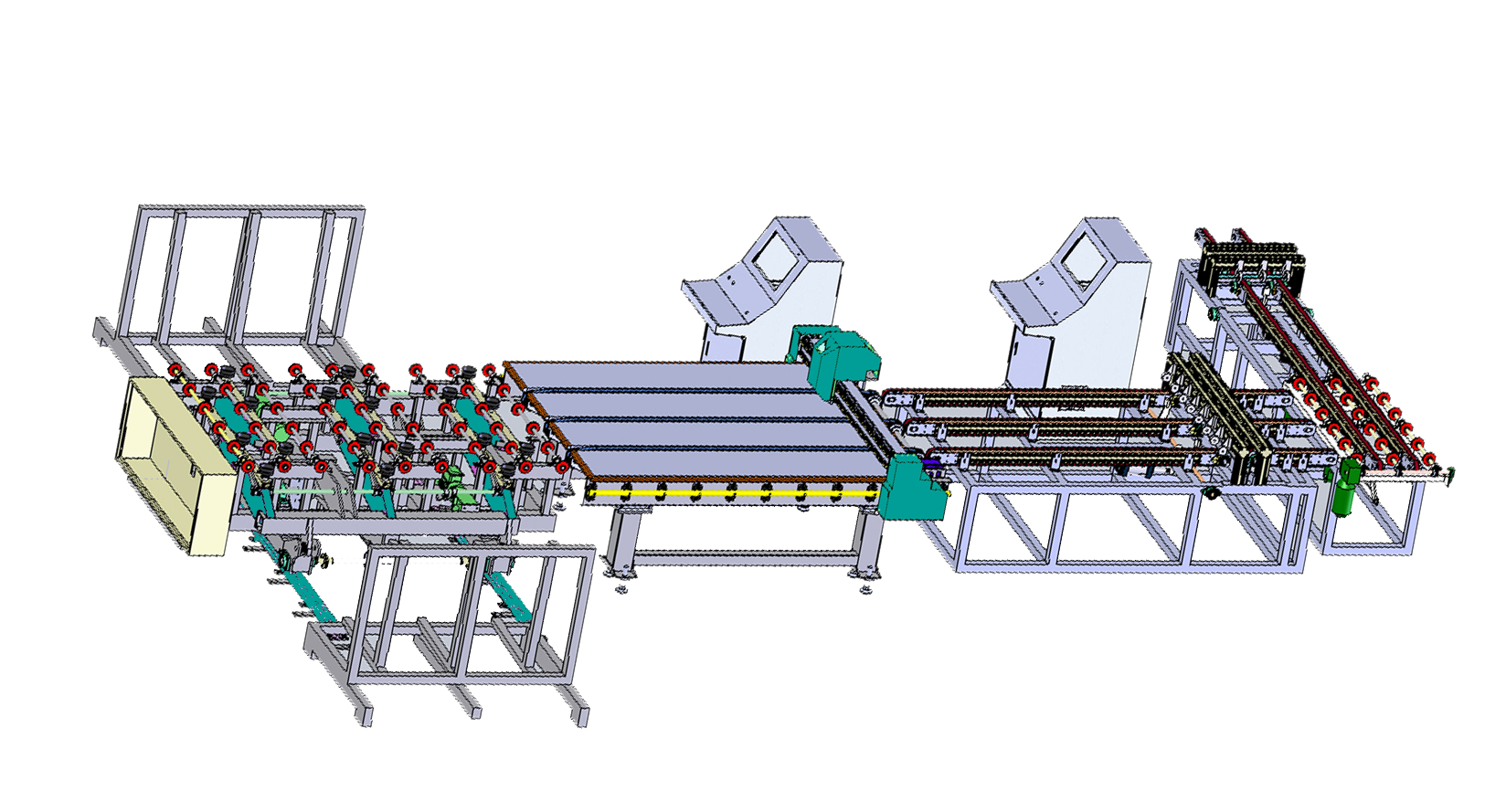

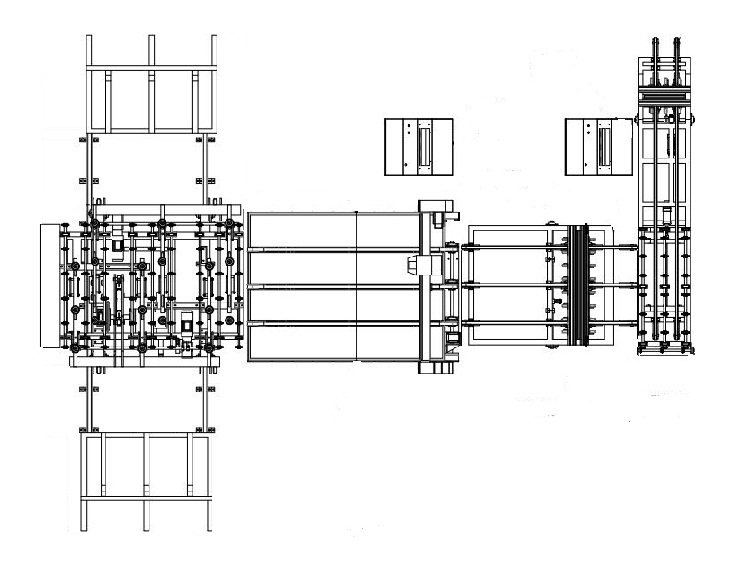

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line Detailed Working Steps

The whole working process can be accomplished by PLC automatic control or manual control. The manual mode is mainly suitable for equipment adjustment and maintenance.

Each action can be completed independently or can be used for normal work.After giving the loading signal (manual and automatic), the arm turns upward about 95 degrees through the overturning mechanism, and the whole machine starts to move forward.

When the induction device on the arm touches the glass, the whole machine stops walking.The vacuum system works, the glass is sucked by the sucker through vacuum systems. When the vacuum pressure reaches the set pressure, the vacuum pump stops. The sucker's telescopic connecting rod mechanism lifts the glass back and up 80 mm through the arm-lifting motor.

Stopping for about 1.5 seconds to make sure the glass is sucked up, the big arm driven by a motor to reverse the glass to the transmission roller. The suction cup under the glass begins to blow, and the telescopic connecting rod mechanism makes the suction cup and the glass fall at the same time.

When the glass falls on the conveyor roller, the small arm continues to fall, the glass is separated from the suction cup, and the conveyor starts to send the glass sheet to the front end of the loading machine and stop at the signal point.Then the whole frame moves automatically to find the zero position and stops.

Waiting for the signal from the cutting table, the glass can be sent to the cutting table at the same speed as the conveyor belt on the cutting machine. After the glass is sent out,automatically repeat the work cycle. The machine can select any position according to the required glass thickness.

Each action can be completed independently or can be used for normal work.After giving the loading signal (manual and automatic), the arm turns upward about 95 degrees through the overturning mechanism, and the whole machine starts to move forward.

When the induction device on the arm touches the glass, the whole machine stops walking.The vacuum system works, the glass is sucked by the sucker through vacuum systems. When the vacuum pressure reaches the set pressure, the vacuum pump stops. The sucker's telescopic connecting rod mechanism lifts the glass back and up 80 mm through the arm-lifting motor.

Stopping for about 1.5 seconds to make sure the glass is sucked up, the big arm driven by a motor to reverse the glass to the transmission roller. The suction cup under the glass begins to blow, and the telescopic connecting rod mechanism makes the suction cup and the glass fall at the same time.

When the glass falls on the conveyor roller, the small arm continues to fall, the glass is separated from the suction cup, and the conveyor starts to send the glass sheet to the front end of the loading machine and stop at the signal point.Then the whole frame moves automatically to find the zero position and stops.

Waiting for the signal from the cutting table, the glass can be sent to the cutting table at the same speed as the conveyor belt on the cutting machine. After the glass is sent out,automatically repeat the work cycle. The machine can select any position according to the required glass thickness.

Technical Parameter

- Sheet size: Min size: 2400*1500 mm (Single Side loading)

- Max loading size: 6100* 3300 mm

- Glass sheet thickness: 3 ~ 19 mm

- Working absorption depth: 700 mm

- X-axis walking speed: 5-25 m/min (adjustable)

- Y-axis walking speed: 8-12 m/min (adjustable)

- Conveying speed: 5-25 m/min (adjustable)

- Number of flip arms: 12 arms (double side loading)

- Number of single arm suckers: Three

- Loading type: Double side loading

- Working cycle: 60 S (30 S for each additional position)

- Installation power supply: AC 380V/50Hz (special circumstances can be adjusted according to customer requirements)

- Installation total power: 8-17 kw

- Compressed air: 0.6-0.8 Mpa;

- Vacuum: -50-99 Kpa (adjustable according to glass thickness)

- Working table height: 900 + 20 mm

- Machine size: 4650*2980*900 mm

Technical Description

- The alarm system: with reliable vacuum detection device, to appear abnormal situation can be automatic alarm and display, can be used to control when abnormal and confirmed The vacuum alarm when abnormal and guarantee under the glass in the vacuum state; When the emergency stop to ensure the vacuum suction cups in a glass in the vacuum state, avoid Avoid glass damage due to abnormal downtime;

- The operation pattern: the device has automatic mode and manual mode two functions for selection, operation convenient and intuitive;

- The operating interface: LCD touch-screen display, Chinese display, convenient operation;

- The main frame, and steel structure all use international quality rectangular pipe compound links and bolt assembly; Rectangular steel tube thickness: over 3-8 mm;

- The material of the machine has been aged, the surface has been rust-removing technology to remove rust spots and surface oxide layer, the bottom layer has been sprayed with high-grade epoxy primer, and the surface has been sprayed with high-gre automobile paint.

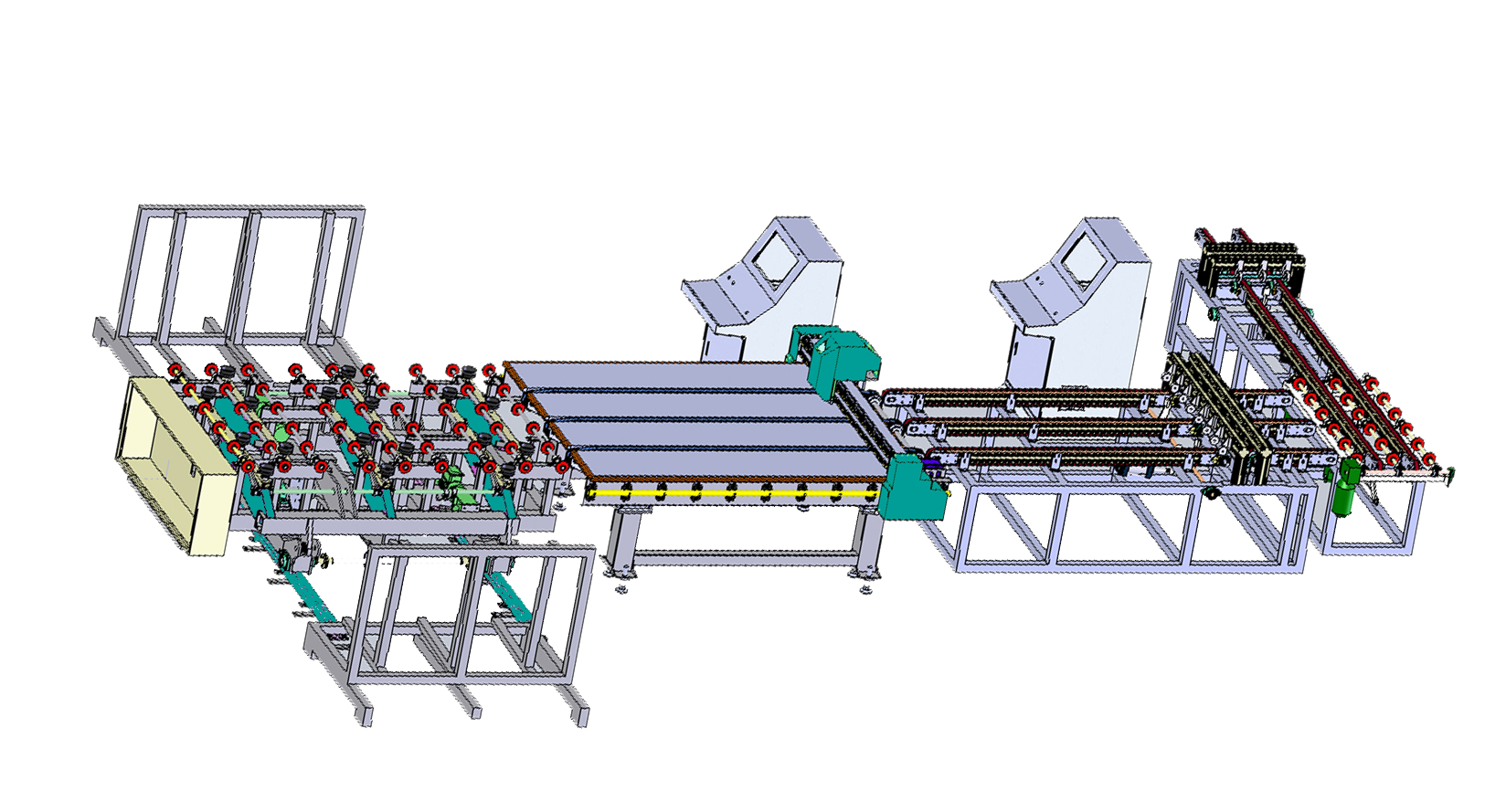

Fully automatic glass feeding, cutting and breaking connection line

Fully automatic glass feeding, cutting and breaking connection line