LJZT02 Manual Insulating Glass Rotated Sealant Spreading Table

LIJIANG LJZT02 Manual Insulating Glass Rotated Sealant Spreading Table is used for fixing and rotating the insulating glass when the processing of insulating glass sealing, easy to operate, simple and flexible...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJZT02 Insulating Glass Two-component Manual Horizontal Rotated Sealant Spreading Table

The insulating glass sealant rotary coating table is a special equipment that seals the outer sealant of insulating glass in a horizontal position and is used in conjunction with Two-component Manual Horizontal Rotated Sealant Spreading Table Coating Equipment. The processing method is to place the two layers of insulating glass installed with aluminum strips on the rotating body. The rotating body is equipped with 4 telescopic support arms to support the glass. The glass is sucked by the suction cup, and the second layer of sealant is applied by rotating. The connector on the processing table fixes the sealant coating tube so that the sealing outlet of the sealant coating tube is against the side wall of the insulating glass for sealant application. When the insualting glass rotates, the insulating glass will push up the sealant coating tube and pass through the connecting piece that can be moved in the moving groove allows the sealant coating tube to move back and forth with the rotation of the insulating glass so that the sealing outlet of the sealant coating tube can always be against the side wall of the insulating glass for the glue coating operation. Continuous without interruption to improve sealant sealng efficiency. After applying sealant, step on the air foot switch and the suction cup will release suction to remove the glass.

Features & Advantages:

- The LJZT02 insulating glass rotary coating table is a workbench used to apply two-component sealant or structural glue during the production of grooved aluminum insulating glass or curtain wall glass.

- The support arm can be telescopically adjusted according to the size of the glass. It has a two-level lifting function and can adapt to different sizes of glass to play a supporting role.

- There is a vacuum suction cup in the support device, so manual support is not required when applying glue; the operator uses a foot switch to control the lifting and rotation of the glass to complete the edge sealing work of the glass. The operation procedure is simple and the use efficiency is high.

- Special equipment for applying secondary sealants on grooved aluminum insulating glass. The worktable can be rotated in 90-degree steps.

- Using advanced indicator lights, knob switches, contactors, and other electrical components, the performance is stable.

Main Technical Parameter

Item. | Spec. |

Air pressure | 0.5~0.8MPa |

Rotation speed | 4r/min |

Power supply | 380V 50Hz |

Total power | 0.37Kw |

Motor power | 0.12Kw |

Operating dimension | 1500*1500mm |

Dimension | 600*550*985mm |

Min. glass size | 175mm*175mm |

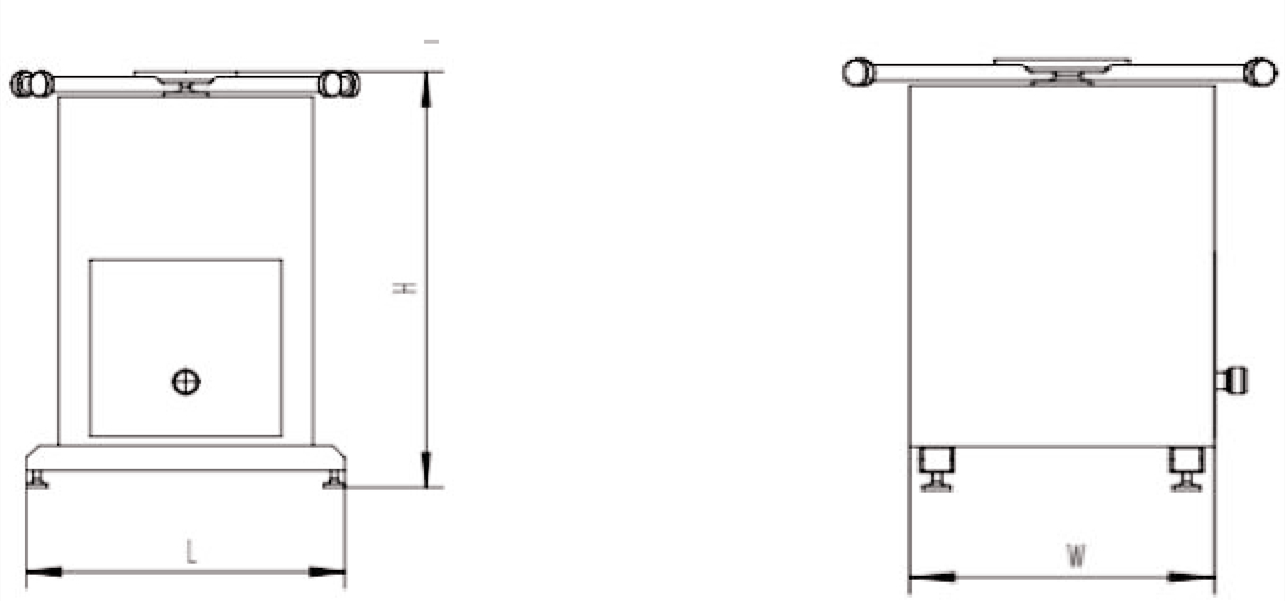

Figure 1 Equipment structure of LJZT02 Insulating Glass Horizontal Rotated Sealant Spreading Table

Figure 1 Equipment structure of LJZT02 Insulating Glass Horizontal Rotated Sealant Spreading Table

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

How to operate the automatic rotating table of insulating glass production equipment

2. After adjusting according to the above procedures, you can proceed with the glue application. After gluing is completed, step on the "lift" switch again to lower the support device and remove the insulating glass.