LJST03 Insulating Glass Two-pump Sealant Spreading Machine

LIJIANG Glass LJST03 Manual insulating glass two-pump sealant spreading machine could adopts anti-back flow control structure to prevent back flow of two-component silicone adhesive, and adopts the mixed rate detector which could control the rate of two kinds of glue...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJST03 Insulating Glass Two-Pump Sealant-Spreading Machine

Product Description

LJST03 Two-pump Insulating Glass Sealant Equipment

Operation method

Operation of a two-component sealant sealing machine

1. Connect the air source

Turn on the source, adjust the pressure-reducing valve to 0.4Mpa~0.6Mpa, and check whether there is air leakage in the system. Then test run the following actions: (1) A pump lifts; (2) A pump inflates; (3) B pump lifts; (4) B pump inflates. Note: When the lifting cylinder is lifted, if the two cylinders are out of sync, please lower it to the origin and then operate again.

2. Place the A and B component glue barrels in place and align them with the axes of the A and B glue pumps.

Take component A as an example:

1) Operate the manual rotary valve to lift pump A to high. During the lifting process, observe whether each pipeline is stretched too tight.

2) Place the glue bucket under the A-pump glue tray, open the glue bucket and the two-component glue machine accessories, turn the plastic bag out of the bucket, and take out the plastic sheet on the glue surface.

3) Slowly lower the pressure plate of pump A. When the pressure plate is put into the bucket, align it with the mouth of the bucket, and open the exhaust port of the pressure plate until the pressure plate touches the rubber surface. When all the gas in the pressure plate is exhausted and a small amount of glue overflows from the exhaust port, the exhaust valve can be closed. (The lift switch remains depressed)

4) Start the machine and try sealing: Turn on the air source switch of the main pump and press the glue gun switch until the air in pump A is exhausted and the glue at the muzzle is continuous.

Use the same method to operate pump B.

3. Sealant sealing operation

1) Loosen the locking screw of the proportional pump on the proportional lever and adjust the inside and outside of the proportional pump to the required ratio. Only when the ratio of glue A and glue B reaches the normal value can the following operations be performed?

2) Set the selection knob to A and B pumps, align the outlet of the glue gun with the middle seam of the two pieces of glass, turn on the glue gun switch, and move the glue gun smoothly at an appropriate speed to fill the glass tank with the two-component glue. good. Close the glue gun when the gluing is complete.

4. Replace the rubber bucket

1) When the glue in the glue bucket is used up, switches A and B should be turned off immediately to stop gluing.

2) Turn on the A (or B) glue pump inflation switch, select the A (or B) glue pump lifting mechanism to the ascending position, and move the knob to slowly lift the pressure plate. At this time, attention should be paid: try not to leave the glue barrel from the chassis until the pressure plate is completely separated from the glue bucket, and turn off the inflation switch of the A (or B) glue pump.

3) Remove the empty bucket, place the new glue bucket in the working position, and repeat operations 3 and 4.

Advantages & Features

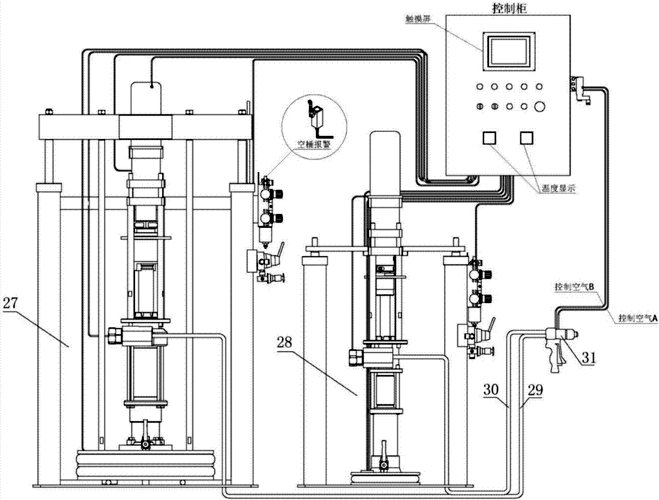

The structural principle of the manual two-component sealant sealing machine

The two-component sealant sealing applicator is composed of A and B glue pumps, a pneumatic system, a lifting mechanism, a frame, etc. They are introduced as follows:

1. Sealant pump:

(1) Components A and B are each equipped with a sealant pump. Driven by their respective pneumatic motors, they make reciprocating motions to suck in and press out the sealing. Sealant pumps A and B are fixed together with the sealant plate respectively, and then connected to the frame to form their systems.

(2) The ratio of components A and B is adjusted through the proportional lever: when adjusted inward, the sealant output of B decreases; when adjusted outward, the sealant output of B increases. By adjusting the proportional lever, the sealant output of B sealant is controlled, thereby controlling the ratio of A and B sealant.

(3) Sealant output: controlled by the air source processor, adjust counterclockwise to increase the sealant output, and adjust clockwise to decrease the sealant output. (This refers to the total sealant output) This sealant pump adjusts the proportion of sealant A and B through a proportional lever. It has the characteristics of flexible operation, stable performance, and a large adjustment range.

2. Lifting mechanism:

Component A and B sealing pumps are each equipped with a set of pneumatic lifting mechanisms. The lifting mechanisms are composed of two parallel cylinders and are fixedly connected to their respective pump bodies through cross beams. One of its purposes is to apply the force of the two cylinders to the rubber surface through the pressure plate. The pressure is adjusted by the pressure regulating valve, generally around 0.3MPa;

Second, when the sealant barrel needs to be replaced, the cylinder can lift the pressure plate. Leave the sealant bucket to replace it with a new one.

Figure 1 Special proportional pump structure of manual two-component sealant sealing machine 1

Figure 1 Special proportional pump structure of manual two-component sealant sealing machine 1

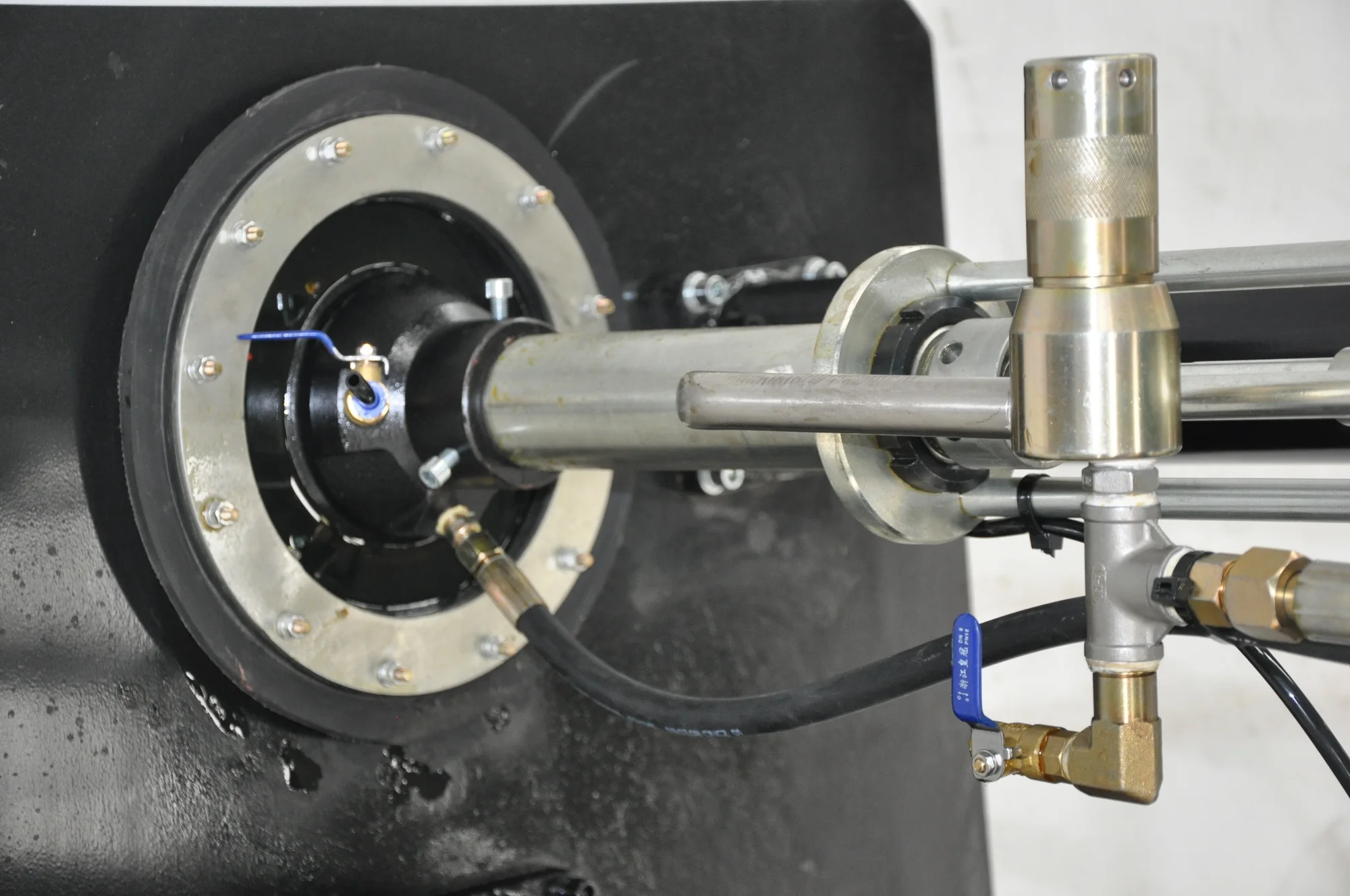

Figure 2 Special proportional pump structure of manual two-component sealant sealing machine 2

Figure 2 Special proportional pump structure of manual two-component sealant sealing machine 2

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Precautions for manual two-component sealant sealing machine

2. Group A and B glue should be kept clean to prevent foreign matter from entering the glue.

3. During continuous operation, the glue gun should generally not stop working for more than 20 minutes at a time. Otherwise, component A glue should be used to flush out all the mixed glue until a single component A glue is discharged from the muzzle.

4. The high-pressure hose must not be forcibly squeezed or bent to prevent it from affecting the normal operation of the system.

5. The glue mixer should always be kept open to ensure good glue dispensing effect. If there is a blockage, soak it in acetone and clean it. It is recommended to clean every 5 sets.

6. When the glue gun has not been used for a long time (more than a week), the gun body should be removed and the residual colloid in the glue gun and glue mixer should be cleaned with solvent.

7. The glue produced by different two-component glue manufacturers contains different amounts of impurities. According to the actual situation, it is recommended to clean the filter screen and one-way check valve of component B once for every two groups.

8. Any failure of the glue gun, pipeline, or entire machine caused by colloid solidification will not be covered by the warranty.

9. Regularly add oil to the oil filling port of each pump. The hollow two-component glue machine should ensure that there is no oil in the oil mist device.