LJSGF01 Manual Insulating Glass Sealant Gun Freezer Equipment

LIJIANG Glass LJSGF01 Manual Sealant Gun Freezer Equipment could storing at low temperature, to prevent the insulating glass sealant solidify, and apply to insulating glass two-component polysulfide sealing and silicone sealant sealing...

- Vendor: LIJIANG Glass

- Shipping:

Learn More

LJSGF01 Insulating Glass Sealant Gun Freezer Equipment

Main Feature

• Storing at low temperature, to prevent sealant solidify inorder to save time and not make any waste fo sealant

• Apply to insulating glass two-component polysulfide sealing and silicone sealant sealing

• Can be effectively reduced waste when cleaning the sealant

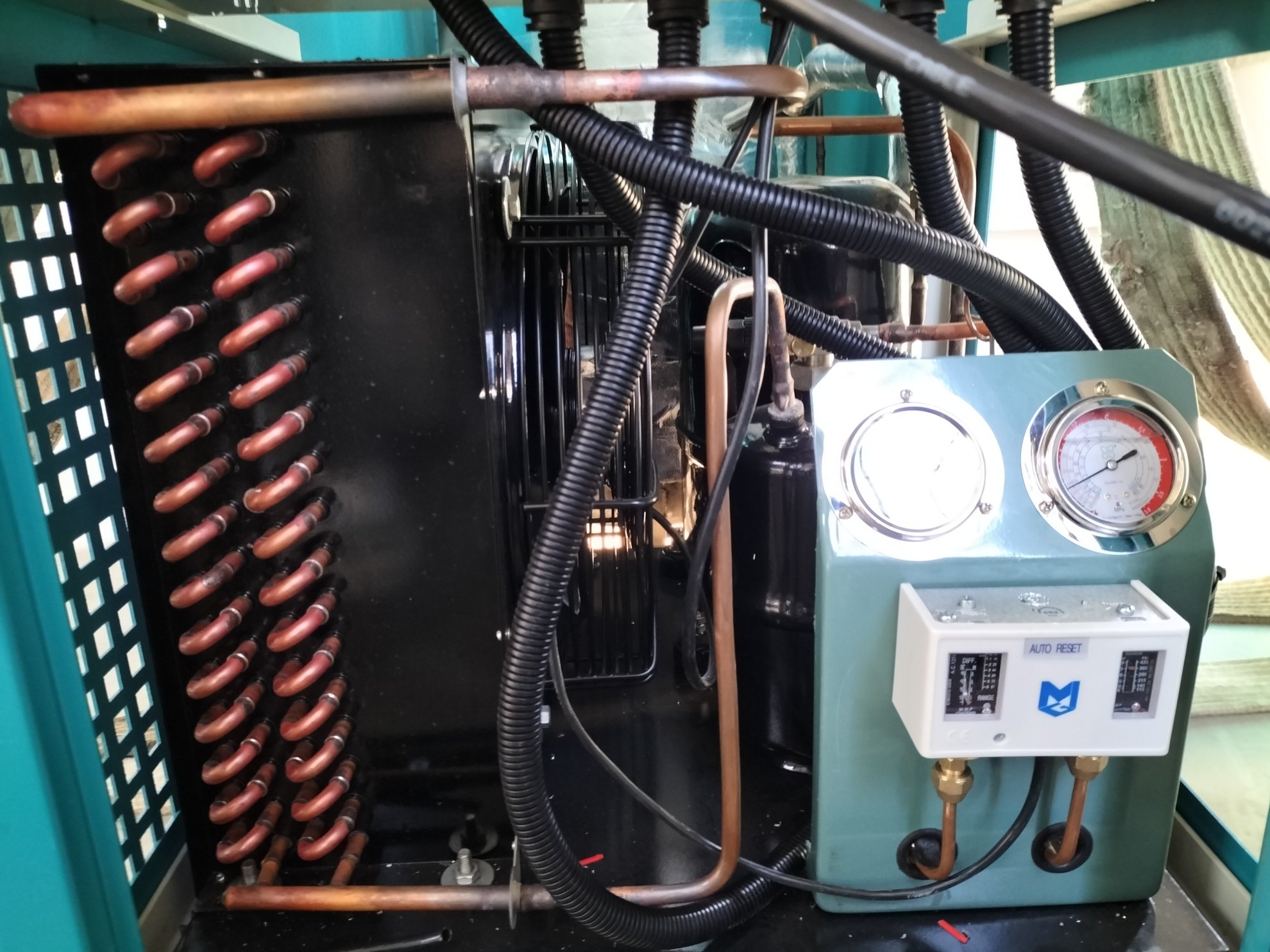

Figure 1 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 1

Figure 1 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 1

Figure 2 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 2

Figure 2 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 2

Figure 3 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 3

Figure 3 LIJIANG Glass Manual Insulating Glass Sealant Gun Freezer Equipment 3

Main Parameter

Item. | Spec. |

Max. refrigerating temperature | 70ºC |

| Min. heating temperature | -40ºC |

| Total power | 3.8Kw |

| Refrigerating | <150min |

| Overall dimension | 1550mm*60mm*1300mm |

Operating Instructions

Operating Instructions for Rotating Gluing Table and Sealing Freezer

1. Turn on the device

- Open the main air valve of the two-component glue machine (the pressure gauge is set to 6 Bar)

- Turn the main switch from "0" to "1"

- Turn on the emergency stop switch with the key

- Press the control switch (Control On)

- Turn Operating Mode to Mixing Switch Seal

- Press the Bydroulil On switch to turn on the hydraulics

- Select the appropriate height by adjusting the pressure gauge of the air pressure equipment. Generally, the position of the glue gun is equal to the height of the rotating sealing table.

- If you use a sealant sealing gun freezer, place the sealant sealing gun in the heating box to heat for 2-3 minutes before using it for better results.

- Use the hydraulic handle to select the flow rate of the sealant, generally 50 Bar. At this time, the two-component glue machine enters the working state of the glue application.

2. Check the semi-finished insulating glass entering the sealing table

- Is there any misalignment between the two pieces of insulating glass?

- Is butyl extruder applied straight?

- Check whether the aluminum frame is installed at an angle

- Is there any dirt or debris between the two insulating glass layers?

- Is there any rebound phenomenon in the aluminum profile spacer frame?

3. Start sealing the two-component silicone sealant

- Turn on the main switch of the rotating sealing table and select the appropriate sealing angle and speed (generally 50% is used)

- Press the left foot switch to raise the rotating sealing table

- Open the sealing gun, start applying the sealant, step on the left foot switch, and rotate according to the set angle and speed.

- After applying the sealant, check the effect of the sealant sealing. If there are any defects, repair or re-seal them.

- After the self-inspection, step on the right foot switch to lower the glue coating table. Use a suction cup to move the finished insulating glass off the glue-coating table (try not to contact the sealing surface with both hands) and place it on the glass shelf. Other parts of the insulating glass must be in contact with the support. The faces are perpendicular, and the two different pieces of insulating glass are separated by foam.

Precautions:

1. The residence time of the mixed sealing in the sealant sealing gun must be controlled within 3-5 minutes, otherwise the buzzer will alarm within a certain period of time

2. Before sealing, check the mixing ratio of the two-component silicone sealant. Squeeze the mixed two-component silicone glue onto a 100mm square, 3mm thick float glass, and then take a piece of the same size and thickness. Press the float glass on the first piece of glass and check the mixed glue effect in a bright place. If there is obvious thread-like white glue or black glue in the mixed glue, it means that the mixing ratio of component A sealant and component B sealant is uneven.

3. Always pay attention to the pressure gauge of the hydraulic mixing ratio equipment. (When the pointer points to the green button, it means safe, and when it points to the yellow or red button, it means danger)

4. Pay attention to the sealant sealing cylinder pressure gauge (component A sealant 6 Bar, component B sealant 4 Bar)

After the work is completed, turn off the manual rotating sealant sealing table equipment, open the sealing gun, and squeeze out all the seal in the sealant sealing gun so that the extrusion pressure is less than 30 Bar. If it will not be used for a long time, first turn on the Operating Mode switch. After the base material is rinsed with Base Purge, open the sealing gun again, extrude all the components A silicone sealant sealing, close the equipment, and continue sealing until the extrusion pressure is less than 30 Bar, then put it into the sealing gun freezer.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.