LJLQ01 Automatic Vertical Glass Washing and Drying Machine

LJLQ01 Automatic Vertical Glass Washing and Drying Machine could wash max glass of 2500 mm*3500 mm, which machine is suitable for deep processing of small format glass, more large size and less size of flat glass washing could be optional.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

KTLQ-01 Automatic Vertical Glass Washing and Drying Machine

Equipment Advantages

Advantages & Benefits

☆The glass washing machine could wash ordinary flat glass or coated glass with a thickness of 3~12mm;

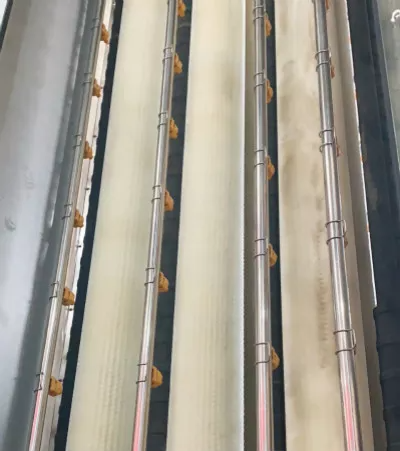

☆The washing area uses 3 pairs of brushes or optional 4 pairs of brushes (or imported soft brushes, coating or LOE special), two or four water cleaning;

☆The machine adopts an inclined vertical structure, the flat glass is placed on the conveyor roller, passes through the feeding section, cleaning and drying section, and reaching the discharging section to complete the glass cleaning task;

☆The washing area and the water tank are made of stainless steel and corrosion-resistant materials; the inclined wind knife with strong wind can dry the glass surface;

☆The discharge section is equipped with inspection lamps to check the cleaning quality of the glass. The machine is easy to operate, and the operation buttons are concentrated on the operating table.

Configuration of three pairs of brushes

Six high temperature resistant wire brushes with diameter of 180mm + four sprays, the glass is cleaned and the speed is fast (10-12m per minute). The first brush is equipped with two bristles and is lifted by a cylinder.

Water rust and corrosion resistant

The parts and screws in the washing box that are in contact with water are made of stainless steel, copper, waterproof aluminum, nylon and other materials. They will not rust after long-term use and are easy to maintain.

High efficiency air knives

Two pairs of stainless steel air knives are equipped with high wind power and good drying effect, with heating system. The unique circulating windshield drying system is energy-saving and low-noise (the wind temperature can reach 40 degrees without heating in winter).

Stainless steel structure

The air-drying box glass support frame is uniformly welded by high-strength stainless steel, and the whole washing parts of glass washing and drying equipment will be used for a long time without rust and will not cause secondary glass pollution.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Common Problems and Solutions during use the Glass Washing and Drying Machine?

A. Check whether the emergency stop is fully opened;

B. If it cannot be turned on, check whether the fuse inside the electrical box is damaged;

C. If it is overloaded, open the power box and press the red button on the heat meter. If the red light goes out, increase the current button of the heat meter appropriately;

2. Not cleaning

A. Check whether the brush has been opened;

B. Whether the water has been boiled;

C. Whether the brush can brush the glass;

D. Whether the brush is worn;

3. The water on the glass does not dry out

A. Check whether the absorbent sponge is adjusted and pressed tightly;

B. Is the red ball valve closed?

C. Whether the fan is turned on and rotating forward;

D. Whether the heating is turned on;

E. Whether the absorbent sponge is damaged;

F. Whether there is oil in the water tank;

4. Leakage phenomenon

A. Check whether there is a ground wire;

B. Open each motor cover to see if any wires are pressed;

C. Check whether the wires inside the rack tube are broken;

5. The water pressure is not good

A. Check whether there is enough water in the water tank;

B. Check whether the water pump is empty;

C. Whether the water tank water inlet is blocked;

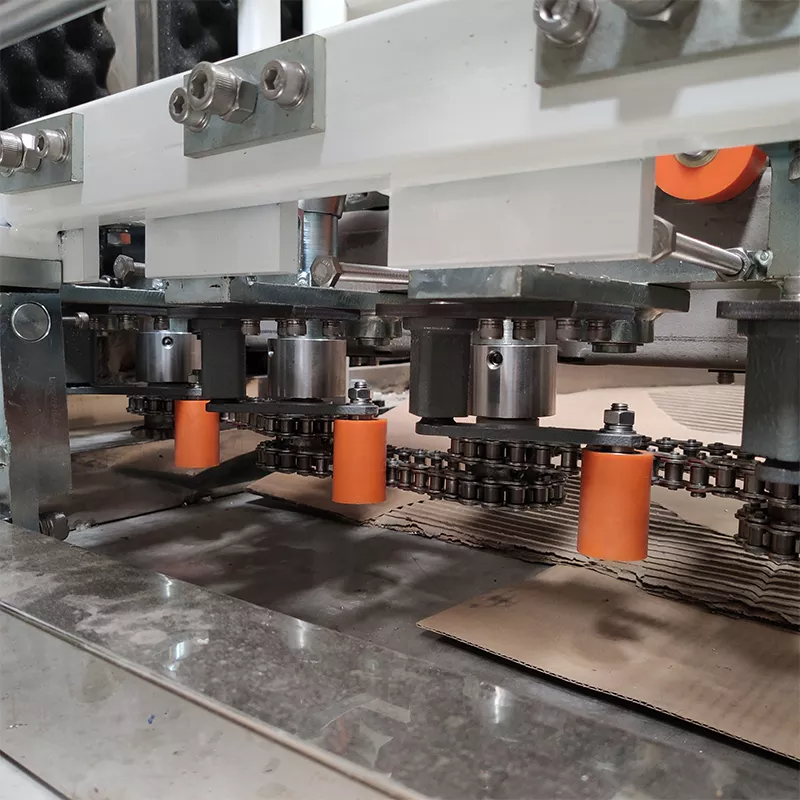

6. The transmission rubber roller does not rotate

A. If it does not rotate at all, check whether the motor is turned on and whether the chain is disconnected;

B. If one of them does not turn, check whether the sprocket screw is locked or the top bar of the lower chain is loosened.

Some Precautions about using Automatic Glass Washing and Drying Machine.

- Pre-spray that is easily overlooked

Regardless of whether horizontal washing or vertical washing is used, the pre-spray device is a very important and easily overlooked place. The pre-spray devices set up by some glass washing and drying machine manufacturers are mostly drilled into stainless steel pipes. In fact, the water spray pressure and water spray volume of this method are not enough. The function of pre-spraying is mainly to remove floating dust and dirt on the glass surface. If the water spray pressure and water spray volume cannot be reached, the glass surface cannot be effectively cleaned, thereby removing the dirt on the glass surface. It enters the glass washing and drying machine with the glass, causing contamination to the roller brush and water tank.

- Regular roller brush maintenance

The key part of glass washing and drying is the roller brush part of the glass washing and drying machine, and regular maintenance of the roller brush is very important. The floating dust, oil stains on the glass surface, and the paper glue of the glass lining paper are easily attached to the bristles of the roller brush, and some are also hidden at the roots of the bristles. If it cannot be cleaned in time, it will contaminate the glass surface being cleaned. Especially for cleaning machines that clean offline Low-E glass, more attention should be paid to regular maintenance of roller brushes. High-pressure water guns can be used for flushing during maintenance. In addition, after long-term use of some vertical glass washing and drying machines, the lower part of the roller brush wears faster than the upper part and also needs to be repaired.

- Re-understand cleaning water

The quality of cleaning water is directly related to the quality of cleaning results. It is not suitable to use tap water, well water, or ordinary purified water to clean glass, because tap water, especially well water, contains a large amount of calcium, magnesium, chlorine, and other ions. The cleaning water should be deionized water with a conductivity of less than 20gS/cm after being processed by water treatment equipment with a deionization function. When processing offline tempered Low-E insulating glass, the requirements for cleaning water are even more stringent. The water in the washing machine water tank should be changed frequently to keep it clean. When changing the water, clean the sediment in the water tank to prevent the water supply pump of the water tank from bringing these sediments to the roller brush.

- Noteworthy air knife design and maintenance

There are many glass washing and drying machines whose air knives cannot completely blow away the water on the glass surface after cleaning the glass, especially when the speed of the glass washing and drying machine is fast. This is mainly a problem with the design, manufacturing, installation, and adjustment of the air knife of the glass washing and drying machine. The key factors are the structure of the air knife of the glass washing machine, the angle between the air knife and the glass, and the wind force of the air knife. In addition, the filter at the fan air inlet should be cleaned in time. Once dust enters the fan, it will be difficult to clean it completely. The glass surface with water blown by the air knife will cause water marks on the glass surface.

During the production process, the cleaning effect of the glass should be checked frequently. A simple and recommended method is to use the mark method, which can visually see the cleanliness of the glass surface.