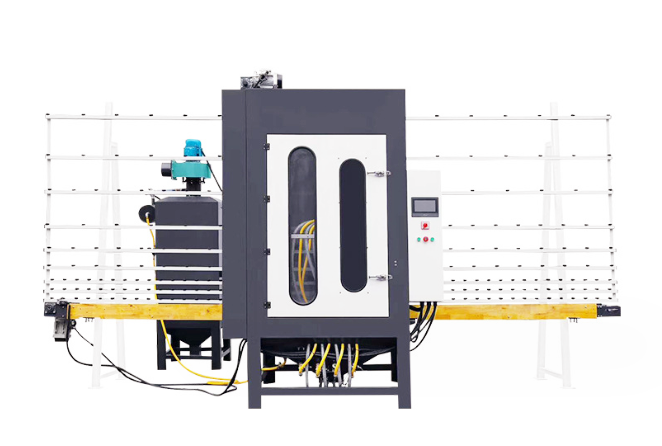

Automatic Vertical Glass Sandblasting Machine

LIJIANG Glass LJPS-1600 / LJPS-2000/ LJPS-2500 Automatic Vertical Glass Sandblasting Machine sucks the sandblasting medium from the sandblasting material box through compressed air, and then sprays it out through the sandblasting gun. When compressed air flows through the sandblasting gun, the air flow speed is accelerated by the shrinkage and expansion of the nozzle, forming a high-speed airflow. Under the action of air flow, the sandblasting medium is accelerated and ejected, impacting the surface of the workpiece for grinding and removing surface dirt. The sandblasting material box and sandblasting pipeline system of the sandblasting machine need to ensure the smoothness and stability of the sandblasting medium to ensure the sandblasting effect.

- Vendor: LIJIANG Glass

- Shipping:

Learn More

Automatic Vertical Glass Sandblasting Machine

Description

LIJIANG Glass LJPS-1600 / LJPS-2000/ LJPS-2500 Automatic Glass Sandblasting Machine designed according to the marketing requirement that is controlled by the PLC, suitable for processing 5-40mm thickness of flat glass to different kinds of frosting patterns. The transmission is controlled by the photo switch and limit switch automatically. Glass is conveyed by the belt, and the guns are driven by a chain so that can be moved up and down for sandblasting (the distance can be adjusted according to the requirement). Stable transmission, high efficiency, and easy maintenance of the chain system. There is a dust-proof cover for the bearing that is onto the drive structure is beneficial to the long period of normal working conditions and daily maintenance. Adopt the PLC for control. The kinds of equipment are with the function of stable running, large-scale function, and easy operation, and can explore the glass position automatically when sandblasting.

Upgrade transmission by frequency conversion control, which can move forward or backward while sandblasting, and with function of gradual Change Sandblasting Processing----Sandblasting depth from shallow to deep.

The equipment has two modes: fully automatic and manual. The machine is equipped with three automatic guns and one manual gun. The lifting of the gun and the transmission of glass are all PLC automatic control by a synchronous belt transmission, the transmission is stable and durable, and the gun lifting device is located outside of the body. Low failure rate. We have modified and upgraded the control program of the machine to facilitate more customers with special requirements.

Figure 1 Automatic Vertical Glass Sandblasting Machine 1

Figure 1 Automatic Vertical Glass Sandblasting Machine 1

Figure 2 Automatic Vertical Glass Sandblasting Machine 2

Figure 2 Automatic Vertical Glass Sandblasting Machine 2

Equipment Structure

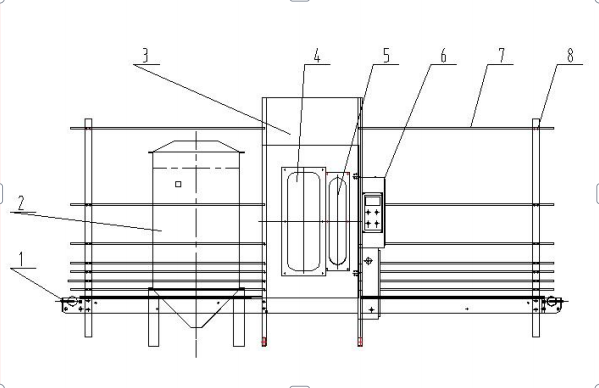

Figure 3 The Equipment Structure of Automatic Vertical Glass Sandblasting Machine

Figure 3 The Equipment Structure of Automatic Vertical Glass Sandblasting Machine

1.Conveyor rail

2.Dust collector

3.Main body

4.Window

5. Window for manual sandblasting

6.Electric box

7. Brush wheel fixed tube

8. Rack

Equipment Specification

| No. | Item. | Specification. | |||

| LJPS-1600 | LJPS-2000 | LJPS-2500 | |||

| 1 | Overall dinension(L*W*H) | 6800*1500*2300mm | 6800*1500*2800mm | 6800*1500*3300mm | |

| 2 | Height of conveyor | 480mm | |||

| 3 | Max Height of glass | 1600 | 2000 | 2500 | |

| 4 | Speed for sandblasting | 28·36㎡/h (use SIC to sand, the quality is better, the height is 2500mm) | |||

| 5 | Air source of exterior | Air output: over 3 lm³/min (It needs storage tamk and compress air cleaner to match) | |||

| 6 | Pressure | 0.6Mpa~0.8Mpa | |||

| 7 | Air compressor | 15kw~22kw 3.6m³ | |||

| 8 | Total power | 3.5kw | |||

| 9 | Machine weight | 1100kg | 1250kg | 1400kg | |

| 10 | Packing size | 2400*1800*2200 | 2800*1800*2200 | 3300*1800*2200 | |

| 11 | Automatic gun | 3 pcs (more automatic gun can be equiped as per customer's) | |||

| 12 | Manual gun | 1 pc | |||

| 13 | Power supply | 380V 50Hz | |||

Main Component

| No. | Item. | Brand. |

| 1 | PLC | Mitsubishi |

| 2 | Touch Screen | MCGS |

| 3 | Encoder | Autonics |

| 4 | Photoelectric Detector | |

| 5 | Intermediate Relay | Omron |

| 6 | Spray Gun,Transmission Stepper Motor 1.8kw | Baishan Motor |

| 7 | Stepper Motor Driver(2 set) | |

| 8 | Spray Gun, Reducer | Kexunda |

| 9 | Transformer | Delixi |

| 10 | Circuit/Breaker/Contactor/Thermal Relay | |

| 11 | Load Switch | Glele |

| 12 | Foot Pedal | Taiwan Tend |

| 13 | Travel Switch | |

| 14 | Blower 2.2kw | Foshan Xieli |

| 15 | Air Hose | ShiQiu |

| 16 | Synchronous Belt | No Interconnecting Type |

| 17 | Spray Gun | Boron Carbide |

Equipment Characteristics

Control by PLC system, easy to oprerate

Adopting stainless steel support frame, sturdy and stable, with long service life.

Glass is transported by belt, using the imported or domestically produced high-quality belts.

Figure 4 Adopts stainless steel support frame

Figure 4 Adopts stainless steel support frame

Adopts red high quality rubber which is long life service time not easy to cause deformation.

Figure 5 Adopts red high quality rubber

Figure 5 Adopts red high quality rubber

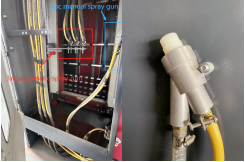

High quality spray gun and nozzle, with long service life. Uniform sand production and good sandblasting effect.

Figure 6 Adopts the high quality spray gun and nozzle

Figure 6 Adopts the high quality spray gun and nozzle

The backing is a special black brush for glass sandblasting.

Touch screen PLC control, using Kunlun touch screen, software operation is simple, easy to use.

Figure 7 Adopts the touch screen PLC control.Each connection switch is clearly marked and clearly.

Figure 7 Adopts the touch screen PLC control.Each connection switch is clearly marked and clearly.

Figure 8 Adopts the marked connection switch.

Figure 8 Adopts the marked connection switch.

Daily Maintenance

1. After the equipment run a certain time, each conveyor belt will be elongate and should be strained promptly to avoid any problem to affect the performance of equipment.

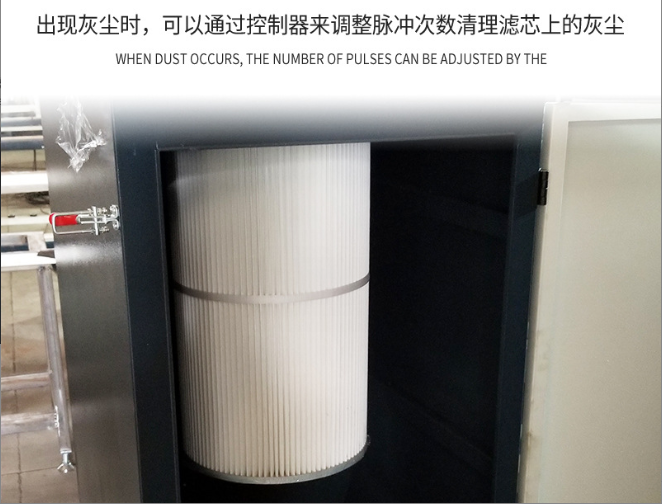

2. It should be add the cerium oxide and clean up the air collector regularly according to the producing condition.

3. Please checks the height of oil level of each motors regularly which if less than 1/3 shouldbe adding the clean normal gear oil. In generally should be change all the lubricating oil of each mechanical driving parts each 6 months, the stepless regulator should adopt the #350 oil.

4. The main drive sprocket and bearing etc. should be change the grease each 3-4months, adopt the ZG-2H lime grease.

5. Each rubber belt will be distortion and ageing because of pulling force when equipment was use longtime. It should be change the belt regularly to avoid any problem affect the efficiency and performance of equipment

6. Please check the inside of equipment regularly, especially the rubber piece use for protecting the spare parts and should change in time if any damage.

7. Please check and clear the filter element of air compressor regularly.

8. Please check and clear the locating switch and encoder regularly.

Services

Pre-Sales Service

1. Free inquiry and consulting support.

2. Free sample-making support.

3. Manufacturing process inspection.

4. Free quotation.

5. Troubleshooting.

After-Sales Service

1. Offering the specifications for the entry-level glass deep-processing machine with 1 years warranty.

2. English software, user manual, and engineer guide.

3. 7/24 technical support by email or call, if you have any problems, we will help you to solve them within 12 hours.

4. During the warranty period, if any part is broken, we will provide it for free.

5. Free remote service and support, if it is necessary, our engineer will come to your country for training.

6. 7 working days to produce the machine, in the meanwhile, we will report the production process in time.

FAQs

1. Is it easy to operate for a beginner?

We provide an English manual or live video guide that will show how to set up and use the machine. Whether you are a beginner or an expert, you can quickly learn to operate. If you still have any problems, please contact us directly via calling or mailing.

2. How to choose the right entry-level glass deep-processing machine?

Yes, to give you a suitable entry-level insulating glass producing machine, please tell me the max working area, materials for processing, and the thickness for the materials to be cut. Then an affordable glass deep-processing machine will be recommended to fit your requirements.

3. If the glass deep-processing machine have any problem after I ordered it, what could I do?

3.1. Free parts will be sent to you in the warranty period if the machine has any problem.

3.2. Free after-sales service life for the machine, please feel free to contact us if you have any problems.

3.3. We will offer 7/24 free service and support by phone, WhatsApp, skype, and mail.

4. What about quality control?

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure it can work very well before being out of the factory. The testing video and pictures will be available before delivery.

5. What about the MOQ?

Our MOQ is 1 set glass deep-processing machine. We could send the glass deep-processing machine to your country port directly, please tell us your port name. There will be the best shipping freight and machine price for you.

6. What about the payment terms?

6.1. 30% by T/T in advance, 70% by T/T before shipping.

6.2. L/C is acceptable, if the amount is big, please issue the draft for our confirmation at first.

7. What about the delivery terms?

We will arrange the delivery on the terms we both agreed upon after the confirmation by the buyer. For standard machines, it would be 7-10 days. For special ordered machines, it would be 15 to 30 days depending on the factory arrangement.

8. What about the packing?

Waterproof plastic film package with foam protection in each corner. Plywood case package with steel belt. It saves space as much as possible for container loading.

9. What about the documents after shipment?

After shipment, we will send original documents to you by DHL which include the packing list, commercial invoice, bill of landing, and other certificates as required by clients.

International Shipping Around the World

All the glass deep-processing machines can be shipped worldwide by sea, by air, or by international express logistics via DHL, FEDEX, UPS. You are welcome to get a free quotation by filling up the form with your name, email, detailed address, product, and requirements, we will shortly contact you with the full information including the most suitable delivery method (fast, secure, discreet) and freight.

Why is glass sandblasting so weak and does not produce abrasives?

1. Blade wear

2. The sand door failed to open successfully

3. The foot switch is not adjusted properly or is damaged.

4. The blade deviates from the track

5. The safety air path is cut off

6. The main pressure regulating valve of the sandblasting machine is damaged.

7. The control pressure regulating valve is damaged.

Method of Exclusion:

1. Turn off the power

2. Check whether the device meets the factory settings

3. Adjust or replace the blade

4. Clean the nozzle or sand box

5. Check whether the passage is smooth

6. Check the sandblasting machine host

7. Check the distance between the glass transfer section and the sandblasting nozzle

The working vision is unclear when glass sandblasting?

1. The vacuum bag is clogged

2. The dust bag is aged and blocked.

3. The sand contains too much dust

4. Compressed air pressure is too high

Method of Exclusion:

1. Vibration sandblasting machine vacuum bag

2. Replace the sandblasting machine dust bag

3. Replace sand material

4. Adjust the pressure to a lower level according to the recommended pressure of the sandblasting machine.